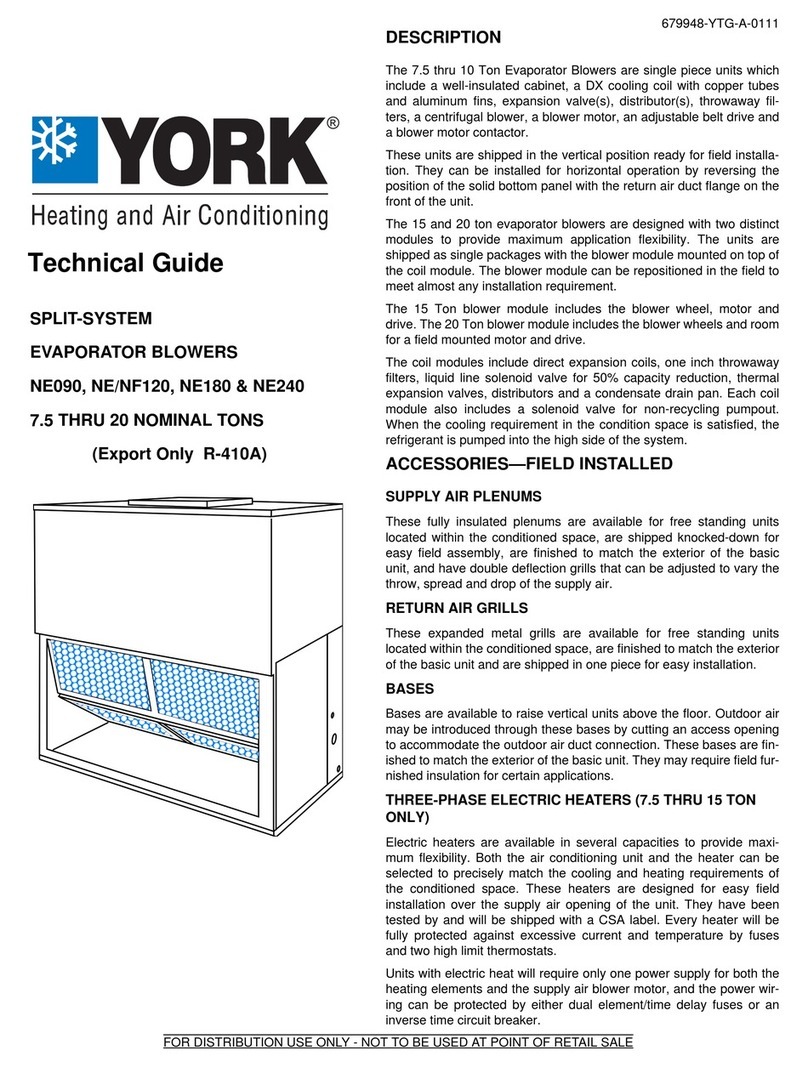

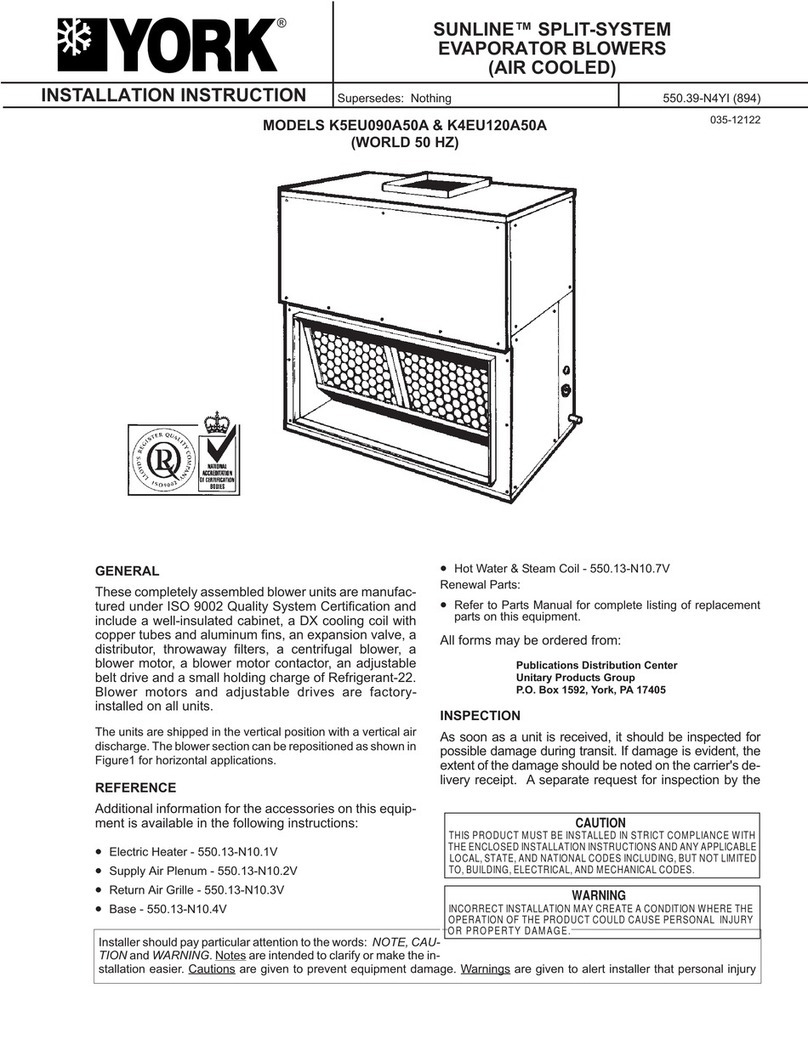

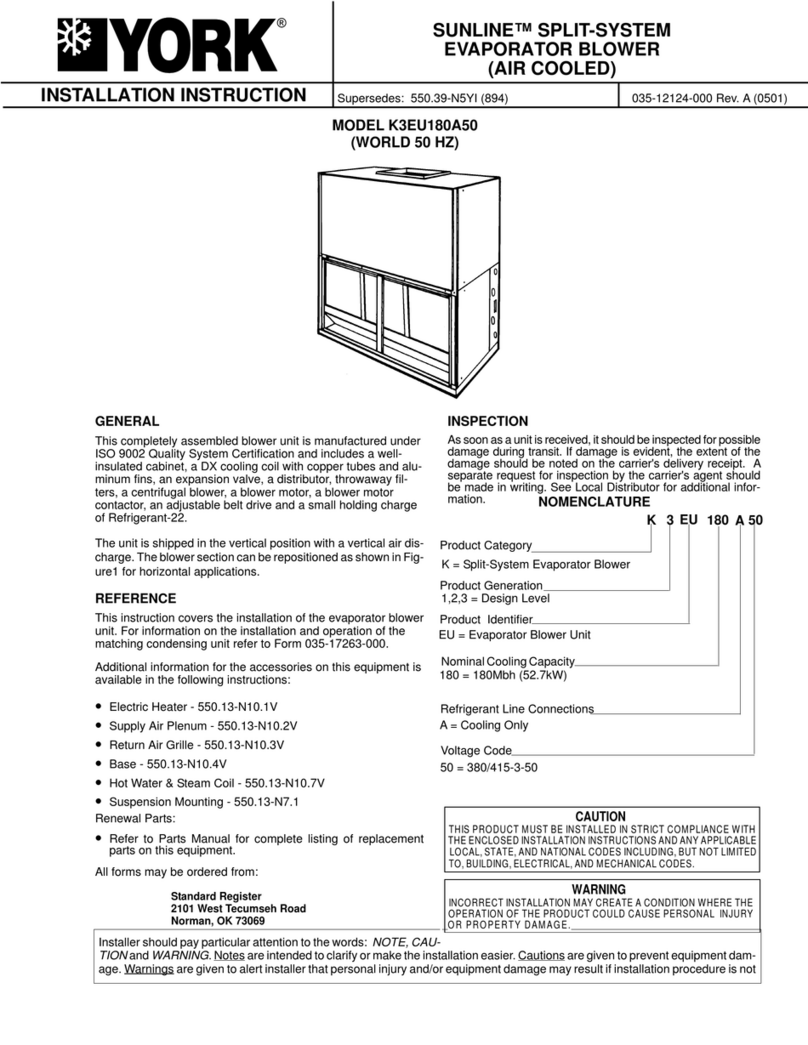

DESCRIPTION

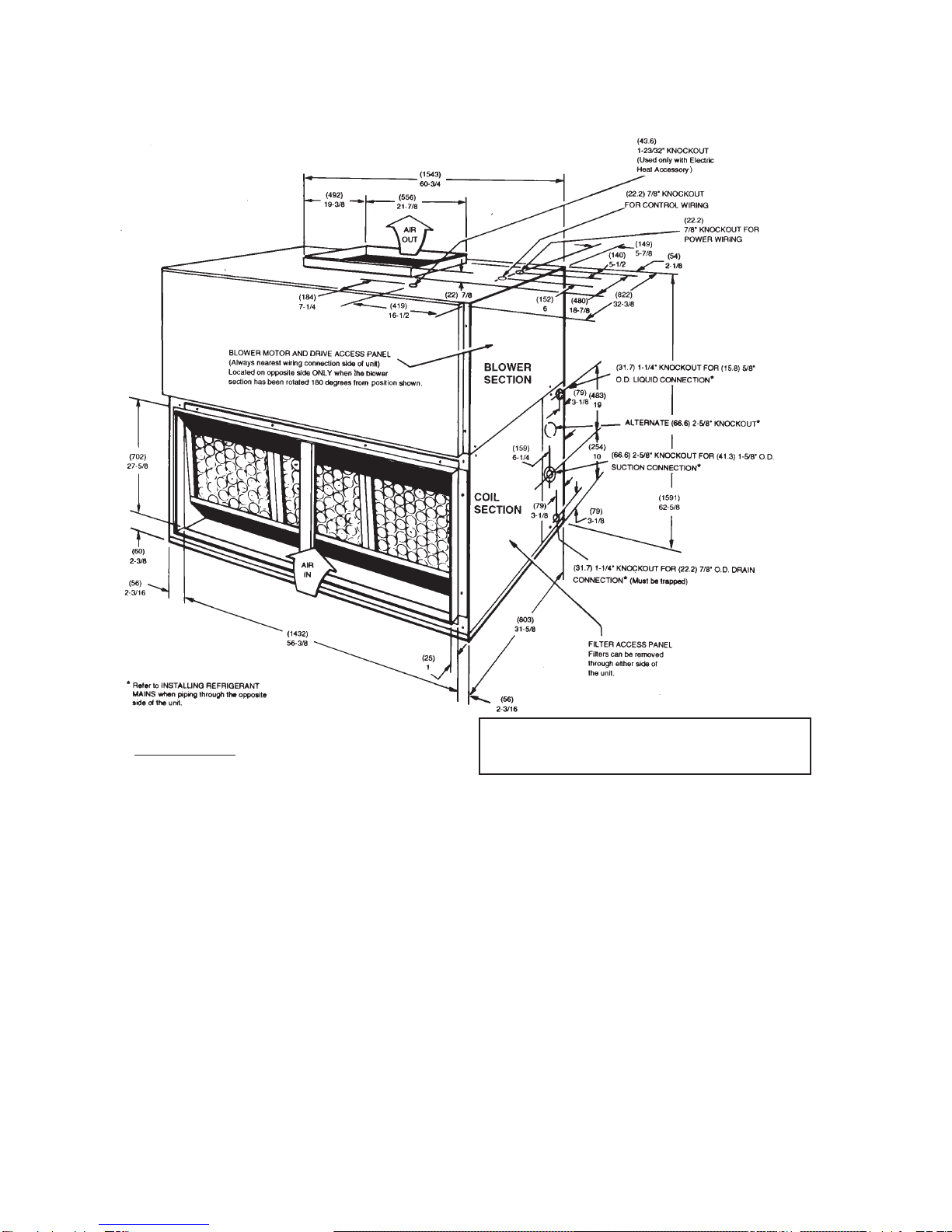

This completely assembled unit includes a well-insulated

cabinet, a DX coil with copper tubes and aluminum fins, an

expansion valve, a distributor, throwaway filters, a centrifugal

blower,ablowermotor,anadjustablebeltdrive,ablowermotor

contactorandasmallholdingchargeofrefrigerant-22.Theunit

ismanufacturedunderISO9002QualitySystemCertification.

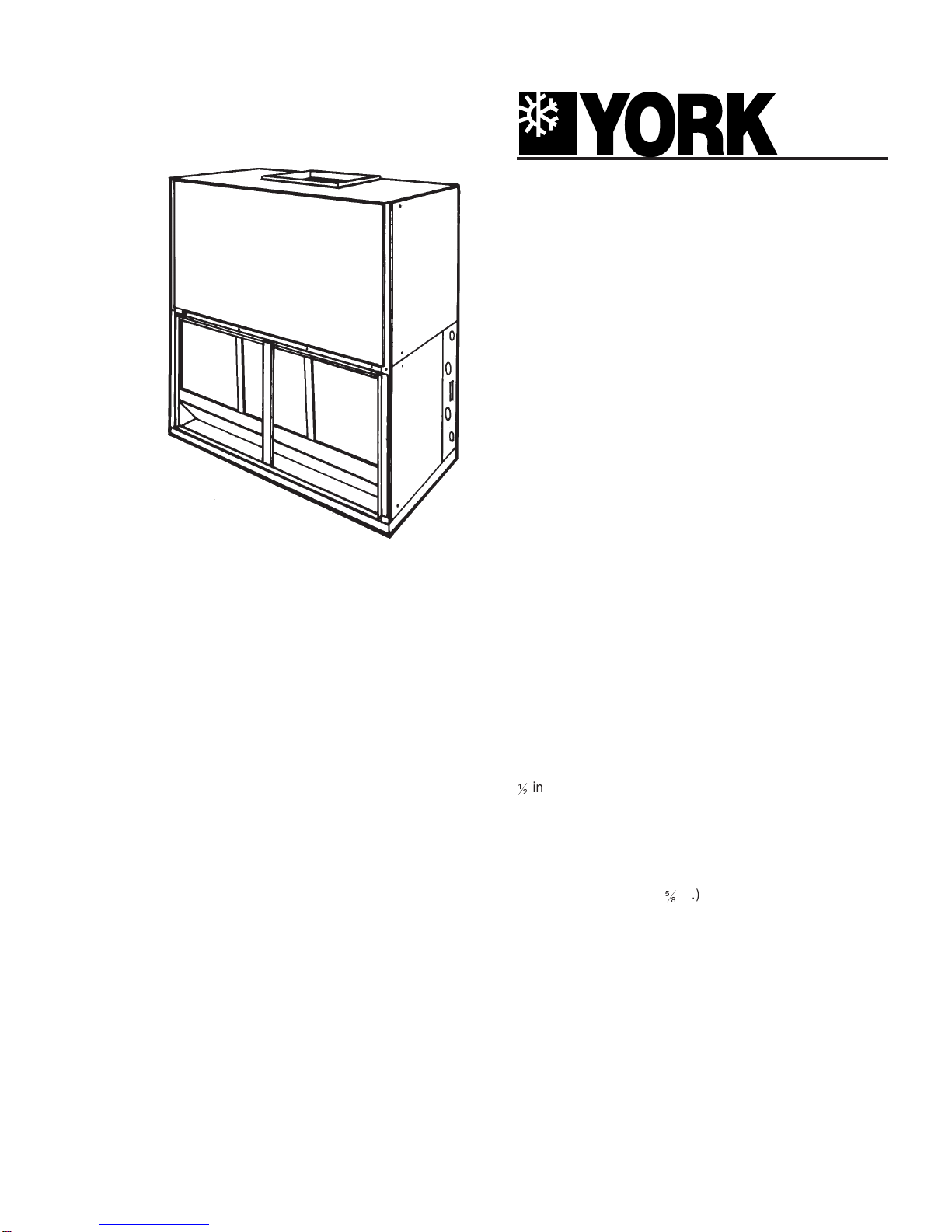

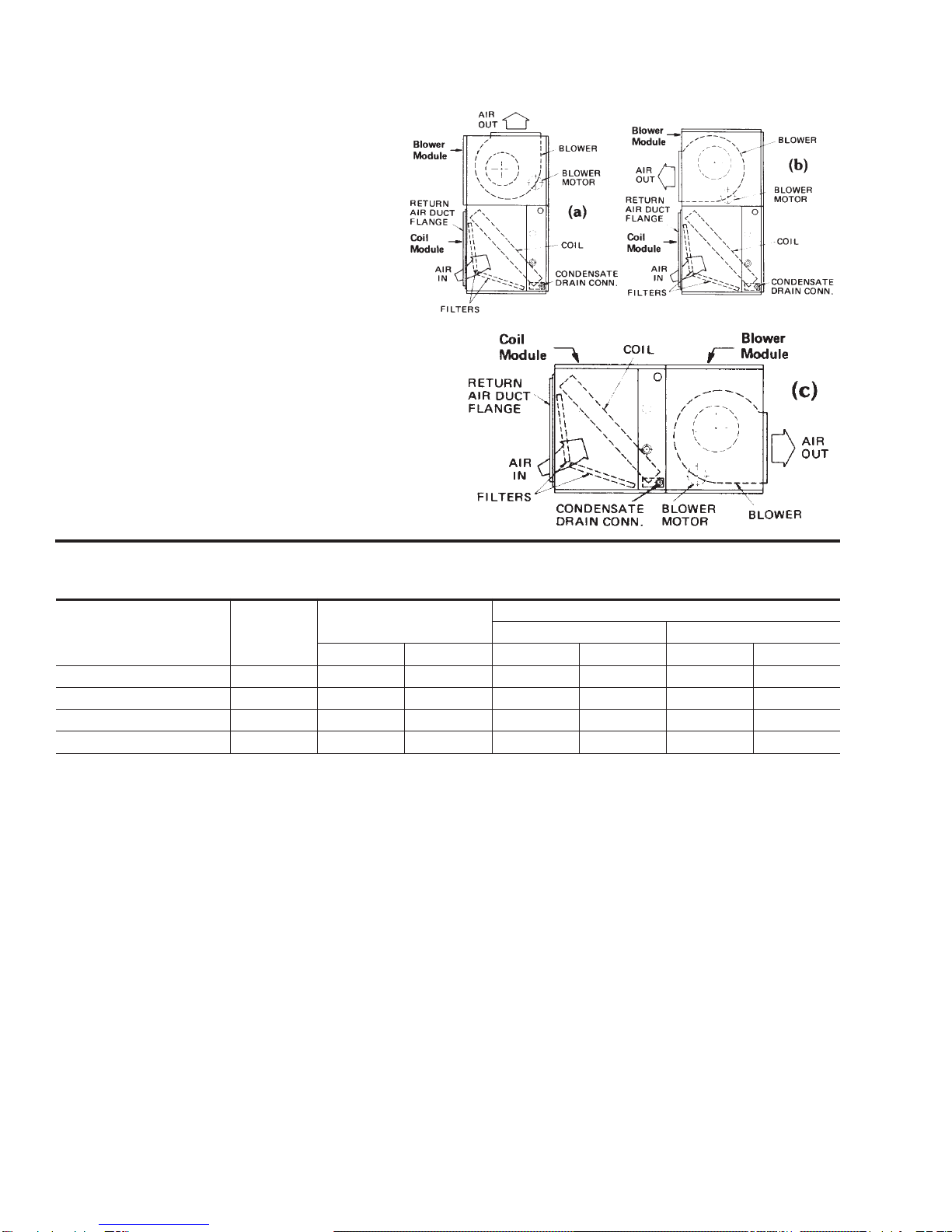

The unit is shipped in the vertical position ready for field

installation. It can be installed for horizontal operation by

reversing the position of the solid bottom panel with the return

air duct flange on the front on the unit.

ACCESSORIES - FIELD INSTALLED

SUPPLY AIR PLENUM - A fully insulated plenum is available

forfreestandingunitslocatedwithintheconditionedspace.Itis

shipped knocked down for easy field assembly, is finished to

match the exterior of the basic unit, and has double deflection

grilles that can be adjusted to vary the throw, spread and drop

of the supply air.

RETURN AIR GRILLE - An expanded metal grille is available

forfreestandingunitslocatedwithintheconditionedspace.Itis

finishedto match theexterior of thebasic unit andis shipped in

one piece for easy installation.

BASE-Abaseisavailabletoraiseverticalunitsabovethefloor.

Outdoor air may be introduced through the base by cutting an

access opening to accommodate the outdoor air duct

connection. The base is finished to match the exterior of the

basic unit. It may have to be insulated in the field for certain

applications.

THREE-PHASE ELECTRIC HEATERS - Electric heaters are

available in four capacities to provide maximum flexibility.Both

the air conditioning unit and the heater can be selected to

precisely match the cooling and heating requirements of the

conditioned space. These heaters are designed for easy field-

installationoverthesupplyairopeningoftheunit.Everyheater

isfullyprotectedagainstexcessivecurrentandtemperatureby

fuses and two high limit thermostats.

Units with electric heat require only one power supply for both

the heating elements and the supply air blower motor. The

power wiring can be protected by either dual element/time

delay fuses or an inverse time circuit breaker.

HOTWATERCOIL-Thisdrainablecoilhastworowsof13mm(

12

in.) copper tubes, eight aluminum fins per 25mm (1 in.), a

casingthatisfinishedtomatchtheexteriorofthebasicunit,but

nowatercontrolvalve.Thecoilslidesoutofthecasingforeasy

fieldinstallation.Itshouldbemountedbetweentheunitcoiland

blower section.

STEAMCOIL-Thenon-freezecoil has one rowof25mm(1in.)

copper tubes, a 16mm (

58

in.) copper tube inside each 25mm

(1 in.) tube to distribute the steam evenly across the entire

length of the coil, eight aluminum fins per 25mm (1 in.), a

casing finished to match the exterior of the basic unit, but no

steam control valve. The coil slides out of the casing for easy

field installation and is pitched in the casing to facilitate

condensate drainage. It should be mounted between the unit

coil and blower sections.

SUSPENSION KIT - Suspension kit 1HH0451 is available for

units installed horizontally. The accessory includes two

channel iron supports and the hardware to secure them to the

topoftheunit.Thehangerrodsmustbesuppliedbythefield.

THERMOSTATS - Wall-mounted thermostats and subbases

(24volt) with system and fan switches are available to control

the operation of these split system air conditioners.

550.39-TG5YI (0601)

SPLIT-SYSTEM

EVAPORATOR BLOWER

K3EU180

15 NOMINAL TONS

SUNLINE 2000

®

(WORLD 50 HZ)