Installation Instructions

Inspection

Upon reception, inspect the equipment and

notify both the carrier and the insurance

company, in writing, of any possible dam-

age.

Environmental protection

Eliminate packing in accordance

with the regulations in force on en-

vironmental conservation.

Installation of indoor unit

Fasten the mounting plate to the wall.

Tighten screws slightly. Level the mounting

plate, and then tighten screws to a maxi-

mum (Fig. 2).

If the tubing goes through the back of the

unit, drill a 50 mm. diameter hole in the wall.

The outer side of this hole should be slightly

below the inner side (Figs. 3 and 7). Install

the through guide.

The refrigerant lines can be installed in dif-

ferent positions (Fig. 6).

Installation of the interconnecting tubing

and wiring, with the central mounting

plate located at the back of the chassis.

Hang the upper part of the unit over the

mounting panel and press forward. Fasten

the indoor unit to the mounting plate per-

manently.

Bend the tubing carefully, without flattening

or obstructing it.

Pass the tubing and cables of the unit

through the hole; and hand the upper part

of the indoor unit on the upper edge of the

mounting plate (see Fig. 2).

Make sure the unit is installed properly,

moving it first to the left and then to the

right.

Condensed water drain

The drain pipe of the unit is flexible and

can be placed in different positions. The

drain line should include an elbow (U-

shaped) (Fig. 4). Connect a plastic con-

densed water drain pipe with a 12 mm. in-

ner diameter.

The drain pipe should be fastened to the

cooling lines with vinyl tape (see Fig. 6).

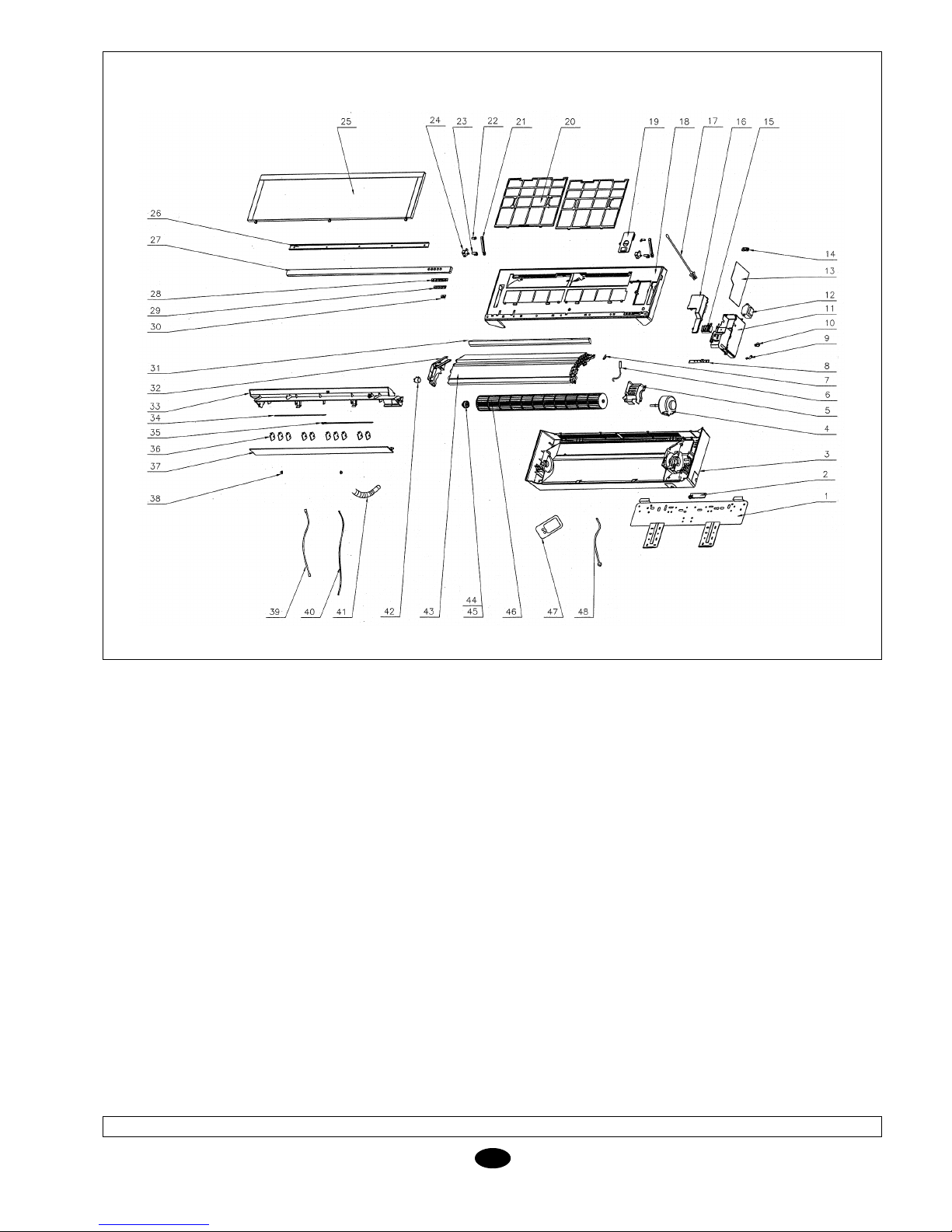

Typical installation (Fig. 1)

This illustration shows, in general, a typical

installation of this equipment.

After carrying out a drain test, apply vinyl

tape, ref. 3, joining all tubing.

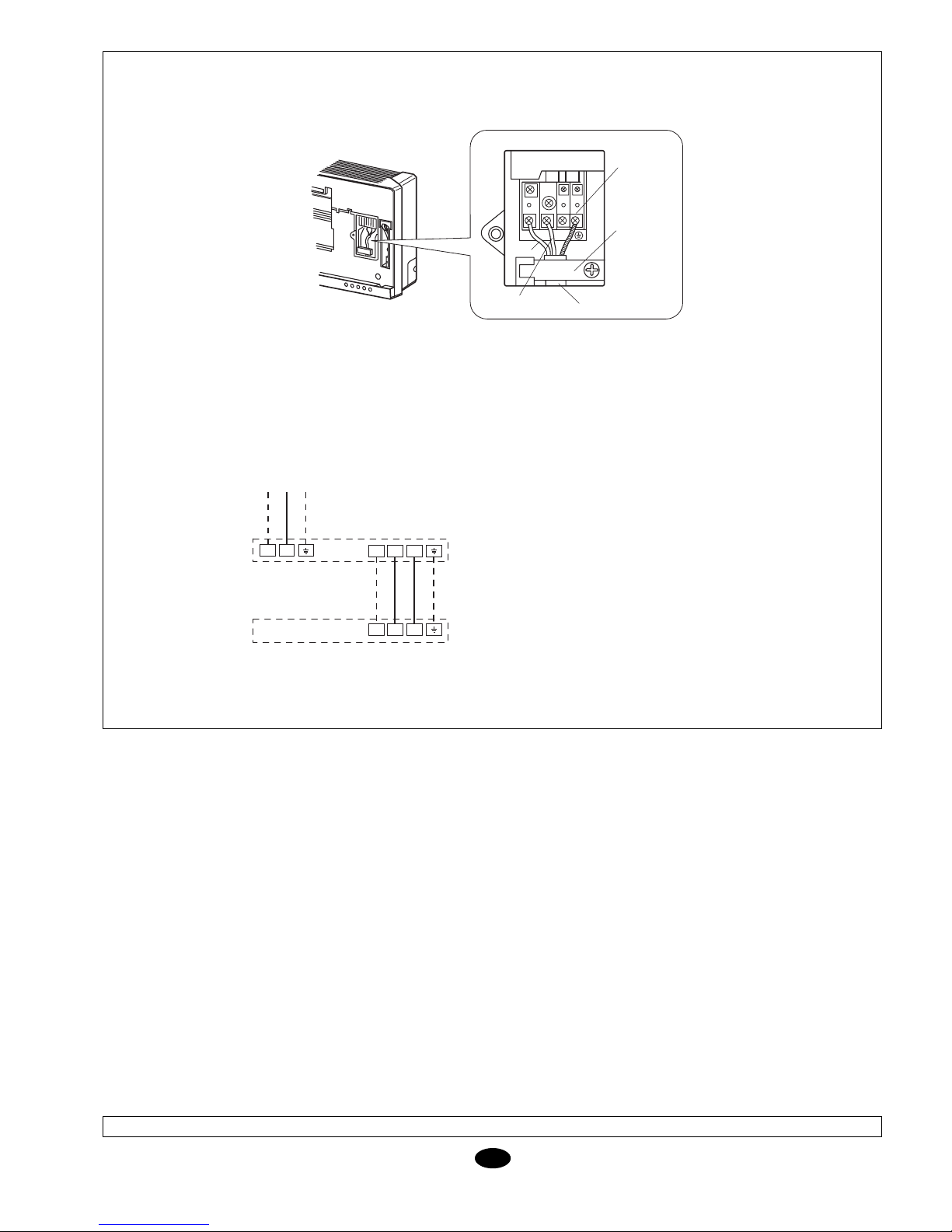

Wiring

1- Open the front panel.

2- Remove the wiring cover.

3- Locate the connecting cable from the

indoor unit, passing though the connect-

ing hole.

4- Connect the blue power supply cable to

terminal “N(1)”, the brown cable to “2”

and the yellow-green cable to the ground

connection, as indicated in Fig. 8.

5- For heat pump models, connect the

power supply cables as indicated in Fig.

8, and fasten the cable to the casing.

6- Install the electrical connection protec-

tor.

7- Mount the front panel.

Cable section

GB

Prior to final approval of the

installation

Check:

- The voltage is always between

198-254 V.

- The power supply cable section

is, at least, that recommended.

- Condensed water drainage is

carried out correctly, and there

are no leaks in the water circuit.

- Operating instructions have

been given to the user.

- Information has been given on

the need to clean the air filter

periodically.

- The guarantee card has been

filled out.

- Maintenance instructions have

been given, or a contract has

been made for periodical serv-

icing.

Sizes

Power supply

Interconnection

(ind./out.)

Fuse (K Curve)

Your product is marked with this symbol. This means that at the end of its service life it should not be mixed

with other non-classified household waste. Therefore, disposal should be carried out in compliance with the

corresponding local and national regulations, in a correct and environment-friendly manner.

The dismantling of the air conditioning unit, as well as the processing of refrigerant, oil and other compo-

nents, should be carried out by a qualified technician and in compliance with the applicable legislation.

Contact your local authorities for further information

ATTENTION

mm2

A

3 x 2,5

3 x 2,5

YVKC09DS YVKC12DS

10

4 x 2,5

4 x 2,5