8

EPDT-351

.2 Precaution for installation

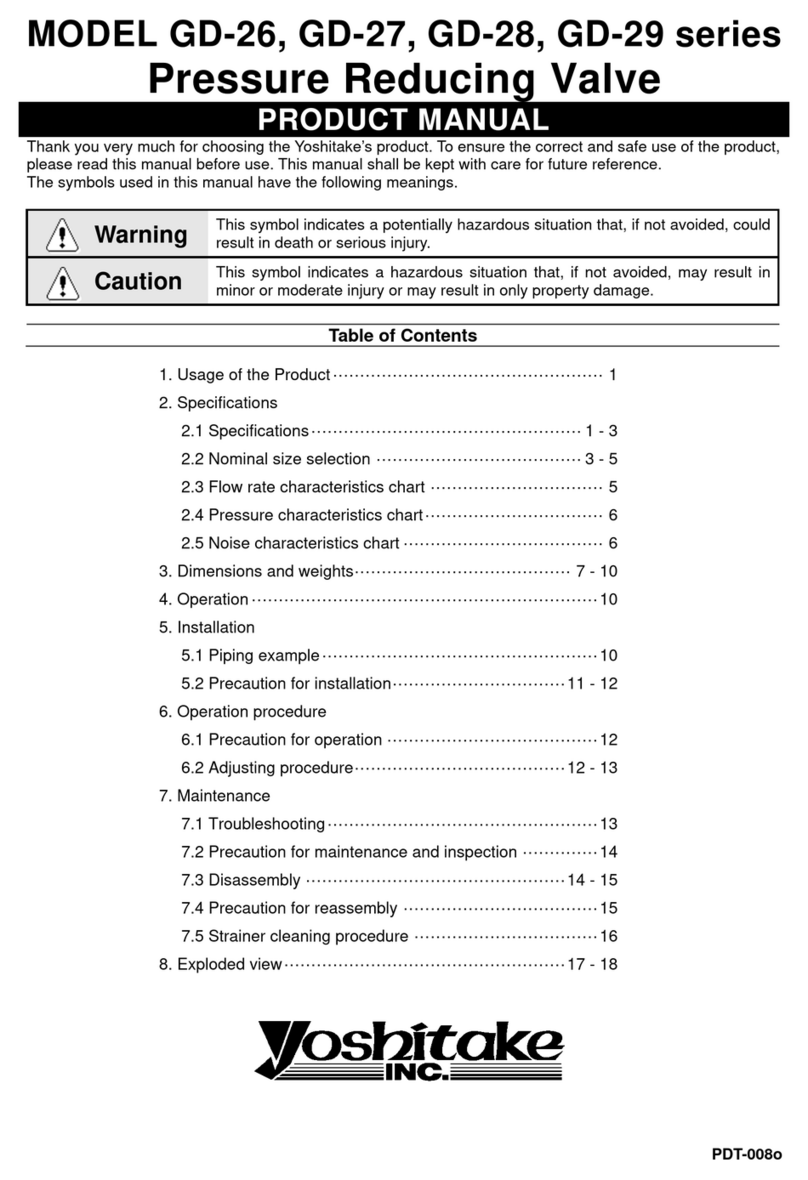

Warning

1. Please refer to “2. Dimensions and Weights.” for product weight.

* Failure to follow this notice may cause a falling accident of the product, resulting in an injury.

2. When installing a safety relief valve for equipment protection on the

outlet side of the product, connect

a blow-off pipe to the outlet side of the safety relief valve, and lead

it to a place where there is no risk

of physical damage even if fluid blows out.

* Failure to follow this notice may result in injury and scalds

in the event that high temperature fluid

blows out.

Caution

1. Do not disassemble the product unless it is necessary.

* Unnecessary disassembly prevents the product from functioning properly.

2.

Before installing the product in the piping, be sure to remove foreign substances and scales

piping. Keep foreign substances from entering the piping, including seal tape or liquid seal agent for

piping connection.

*Ingress of foreign substances, scales

or seal agent into the product leads to valve leakage or

malfunction of the product.

* Repairs caused by foreign substances or scales will be charged even during the warranty period.

3. If components having a negative influence on internal parts are incl

uded in fluid or surroundings,

deterioration of rubber parts is accelerated and then outside leakage or functional disorder is caused.

4. Be sure to install a strainer on the inlet side of the product of nominal size 65A to 100A.

*Ingress of foreign substances or scales

into the product leads to malfunction of the product. It is

recommended to use a strainer of 60 mesh or more.

5. Install a safety relief valve for equipment protection on the outlet side of the product.

* Failure to follow this notice may result in damage of the equipment.

6. Be sure to install pressure gauges on both inlet and outlet sides of the product.

* Failure to follow this notice hampers correct pressure adjustment.

7.

If a quick operating valve such as a solenoid valve is installed, place it at a distance of at least 3 meters

from the product.

* Failure to follow this notice

may result in malfunction or a drastically shortened service life of the

product.

8. Install the product properly by checking the inlet, outlet and proper posture.

* Installing the product in wrong directions prevents the product from functioning properly.

9. Install pipes so that excessive load, torque or vibration is not applied to the product.

10.

Make sure that pipes 3m before and after the product, the inlet side and outlet side, are of the same

diameter.

* If the pipe diameter is narrowed immediately before or after the product, the flow velocity may increase

and result in malfunction or a drastically shortened service life of the product.

11.

The product can be installed either horizontally or vertically.

12.

A space more than the value shown as H2 in the table below is required for disassembly and inspection.

A space more than the value shown as H3 in the table below is required for the inspection of the built-in

strainer (nominal size 20A to 50A).

13.

For two-stage pressure reduction, keep a distance of at least 3 meters between each product.

*Failure to follow this notice may prevent the product from functioning properly due to malfunction.