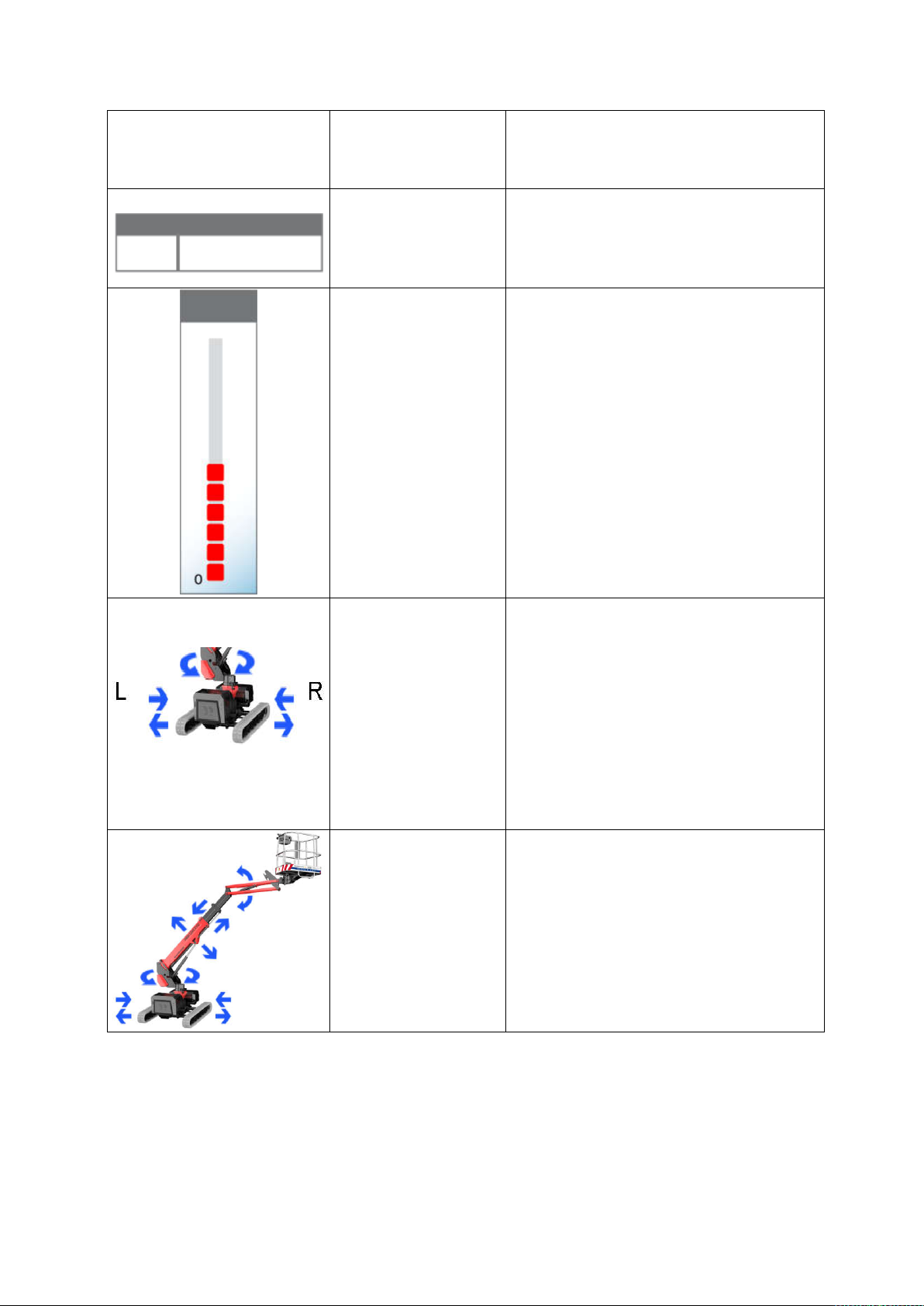

No

Identification Function and Status Description of the function

endothermic engine accelerator is

activated;

Turning the device anti-clockwise (-)

decreases the currents to the proportional

valves. Moreover, with the selector below

50% the accelerator of the internal

combustion engine is deactivated and the

movements can only be carried out

8 Selector

Selection of

endothermic engine

or electric motor

To select the combustion engine, turn the

selector upwards;

To select the electric motor, move the

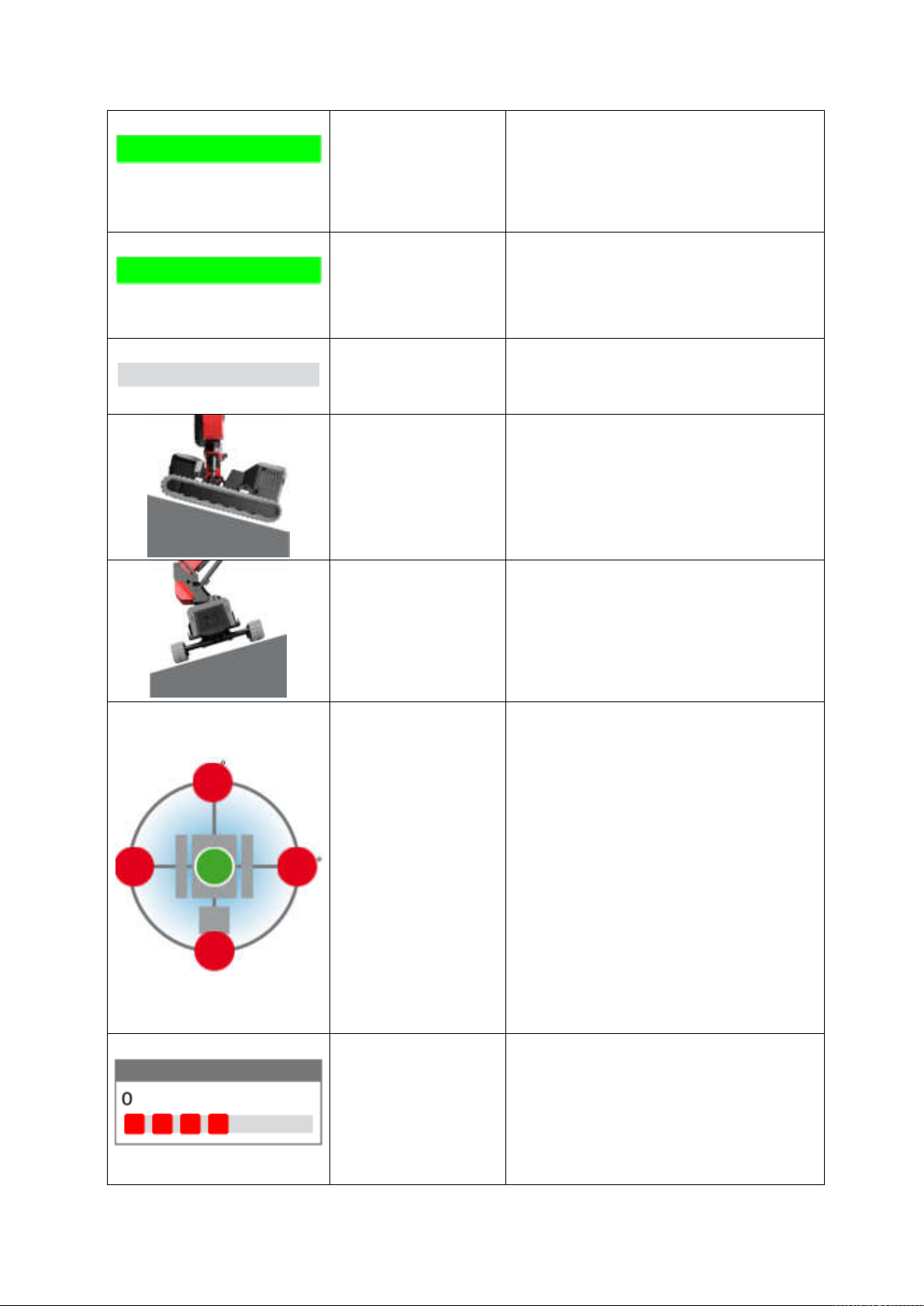

9 Selector Antenna movement

control (JIB)

To raise the antenna (JIB), move the

selector upwards keeping it in position;

To lower the antenna (JIB) move the

selector downwards keeping it in position;

Note: This command only works after

having previously activated the aerial part

using the selector 6 (Blue “LIFT” selector).

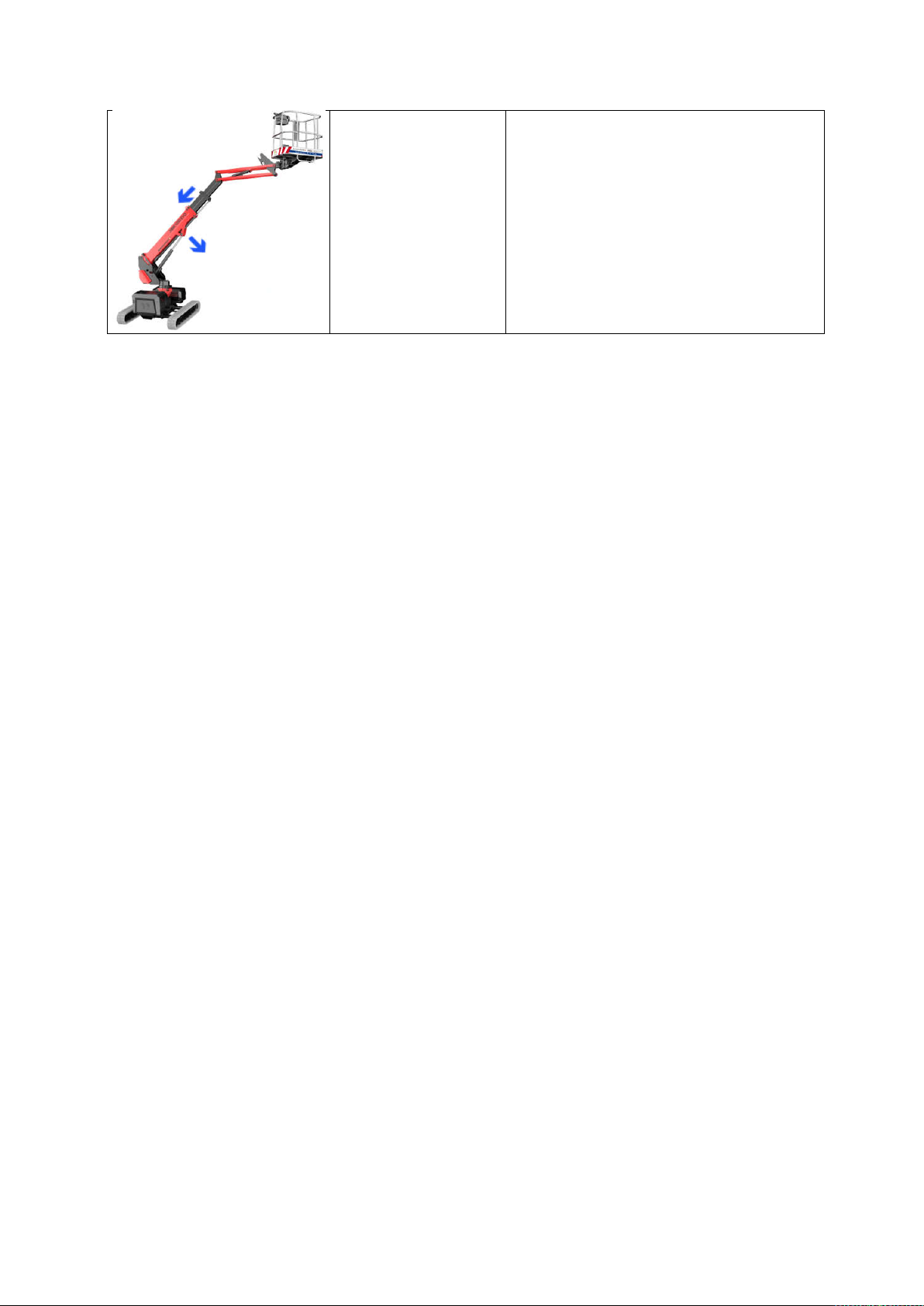

10 Selector Winch movement

control (if present)

To lower the hook of the winch, move the

selector downwards keeping it in position;

To raise the hook of the winch, move the

selector upwards keeping it in position.

11 Purple (FAST

DRIVE) button Fast drive activation

-

Press and release to activate the

Booster.

- Optional mode: translation control

command with the right Joystick

only.

12 Safety key

(KEY)

Safety key for

console activation

Insert the supplied key to activate the

console;

If the key is not inserted, the console cannot

be activated;

The key is encrypted so use only the key

provided, otherwise the console cannot be

13 Button

Ignition of the

Press and release to turn on the console.

14

Green

(MANUAL)

Activation of the

manual levelling

Press to activate the manual levelling

controls using the left joystick.

15

Button

(Warning

Warning Buzzer

Activation Press to activate the warning buzzer.

16 Connector Connector for coiled control cable.