12 BoSS X-Series Instructions for Use

3 - Safety rules3 - Safety rules

These safety rules should be adhered to in

every way.

NEVER exceed the 240kg rated capacity

(Safe Working Load or SWL) of the

platform

NEVER use the BoSS X-Series machine as a

crane

NEVER attempt to increase the reach or

working height of the BoSS X-Series

machine by use of additional

equipment eg ladders

NEVER use the BoSS X-Series machine in

temperatures exceading 50oC or

below -20oC

NEVER manoeuvre the BoSS X-Series

machine on an inclined surface

otherwise it may become

uncontrollable

NEVER release the brakes or manoeuvre the

BoSS X-Series machine whilst in an

elevated position as this may cause

instability

NEVER manoeuvre the BoSS X-Series

machine with a person or materials

on the platform.

NEVER attempt to get on or off the work

platform of the BoSS X-Series

machine when elevated

NEVER apply external side loads to the

platform or scissor structure

NEVER allow persons at ground level to

operate the controls whilst the

platform is occupied (unless in an

emergency situation)

NEVER operate the BoSS X-Series machine

outdoors

NEVER use the BoSS X-Series machine as

a jack, prop or tie to support other

structures or machines etc.

NEVER interfere with, wedge or attempt

to override hydraulic, electrical or

mechanical safety devices

NEVER remove the platform guardrails when

the machine is in use

NEVER allow works overhead of the BoSS

X-Series machine to be carried out

which are outside the control of the

operator

NEVER use the BoSS X-Series machine as

an electrical earth when welding

structures alongside it

NEVER use the guardrails to carry materials

NEVER attempt to overreach

ALWAYS check that there are no

obstructions or persons that

may be struck by the platform

before and during the raising and

lowering of the platform

ALWAYS carry tools and materials within

the confines of the guardrails of

the work platform

ALWAYS undertake the daily checks

recommended in this handbook

prior to the operation of the machine

ALWAYS ensure that all instructions, warning

and safe working load labelling

and plates are clean and legible

ALWAYS ensure the BoSS X-Series machine

is positioned on adequate ground

to support the weight of the

machine and its rated load.

ALWAYS keep the BoSS X-Series machine

clear of live electric conductors

ALWAYS keep the BoSS X-Series machine

away from contact with fixed

objects (buildings etc) or moving

objects (vehicles, cranes etc)

ALWAYS ensure hands are within the

confines of the guardrails when

elevating the work platform

ALWAYS ensure the access gate is closed

and latched once the operator has

entered the work platform

ALWAYS ensure that another responsible

person on site knows how to use

the emergency controls

ALWAYS ensure the weight is evenly

distributed within the platform

ALWAYS ensure the safety of persons that

may enter the area around the

platform and keep other vehicles

clear of the work area (eg cordon off

areas to prevent persons and other

vehicles entering the danger area)

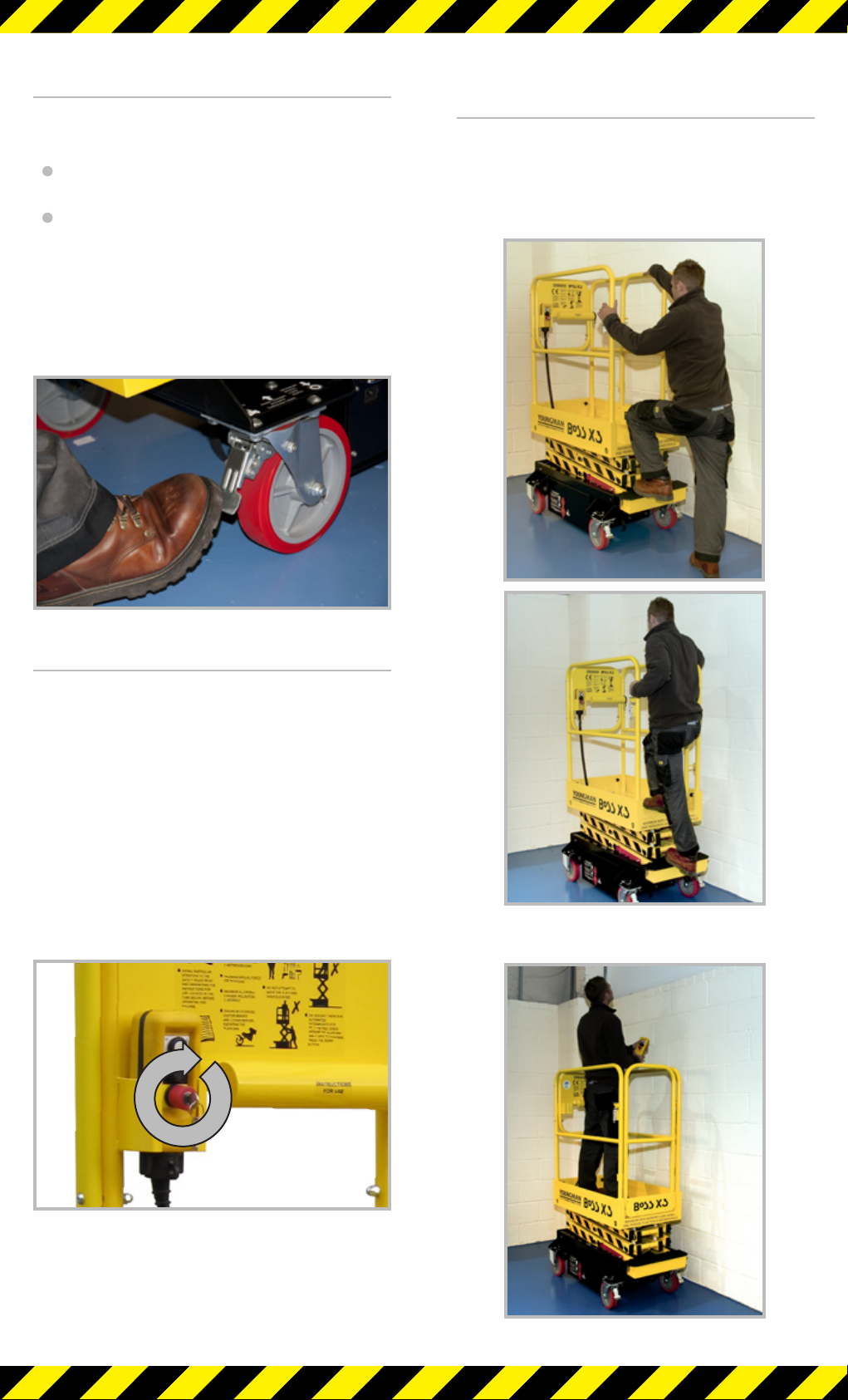

ALWAYS lock the swivel castors when

machine is stationary whether or

not it is in use

ALWAYS ensure the tilt sensor alarm

sounds when the power is

switched on

ALWAYS ensure the battery is charged

before use

ALWAYS read and understand these

Instructions for Use before using

the machine

ALWAYS use fail-safe props if working

under the work platform

ALWAYS thread the hoisting straps inside

the guardrails when hoisting the

machine

ALWAYS check that the LOLER certification

of the machine is in date before

use (UK ONLY)