2

Overview

AI-5500 Handheld Economical Digital Thermometer, features high precision, high

stability, low power consumption, multiple input types, multiple measurement results,

easy operation, etc. When suitable sensors are matched, it can be widely used for

handheld precise temperature measurement in production, scientific research and labs.

Its main characteristics are as follows:

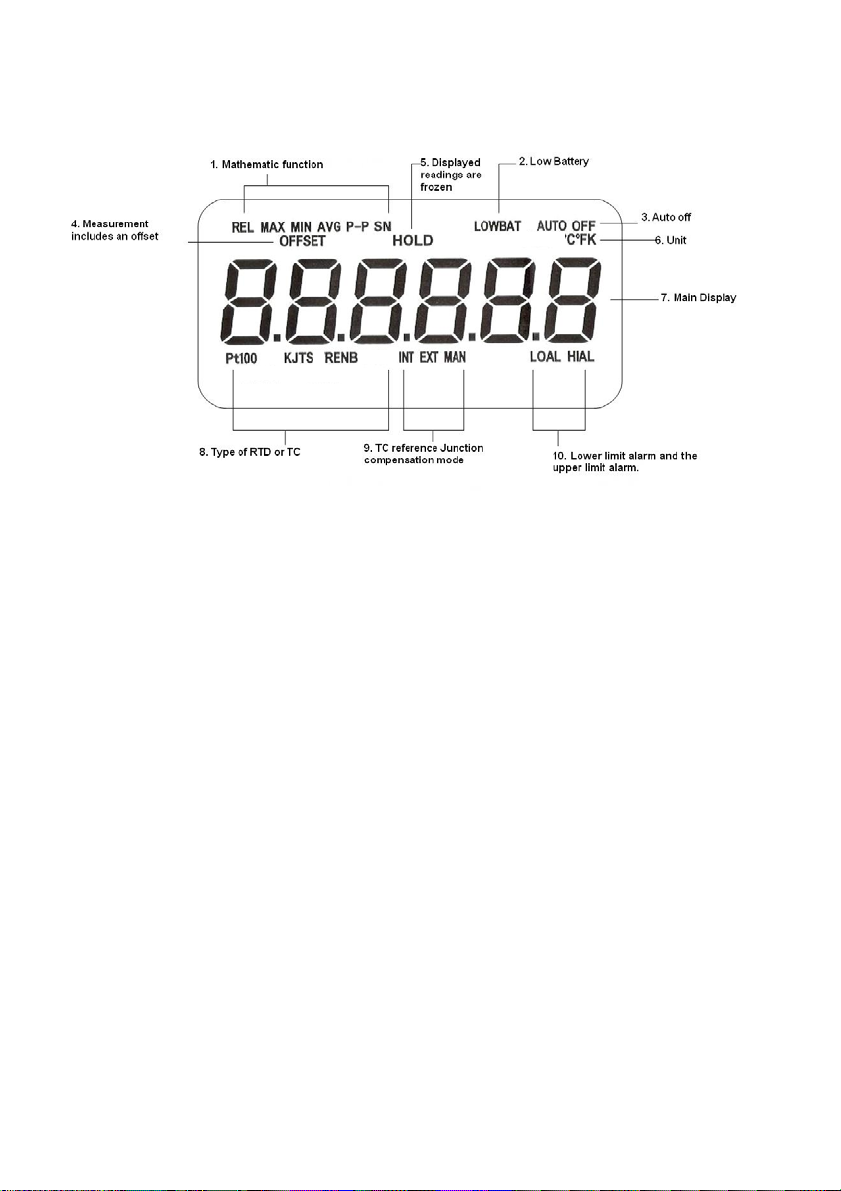

Input types:

Pt100, K, S, E, T, J, R, B, N. There are three compensation modes for thermocouples,

including internal compensation, external compensation and manual(simulated)

compensation.

Mathematical-statistical measurement:

Relative value, maximum value, minimum value, average value, peak-peak value,

standard deviation and sampling number can also be measured at the same time.

Resolution can be set:

0.1 oC/ 1 oC

Display units for thermal resistances and thermocouples:

Which can be switched at will, including oC, ℉and K.

Customized start-up display:

Including math modes, resolution, display units and the reference junction

compensation modes.