Charging Pile Instructions-V2.0

Contents

1. INTRODUCTION ............................................................................................ 1

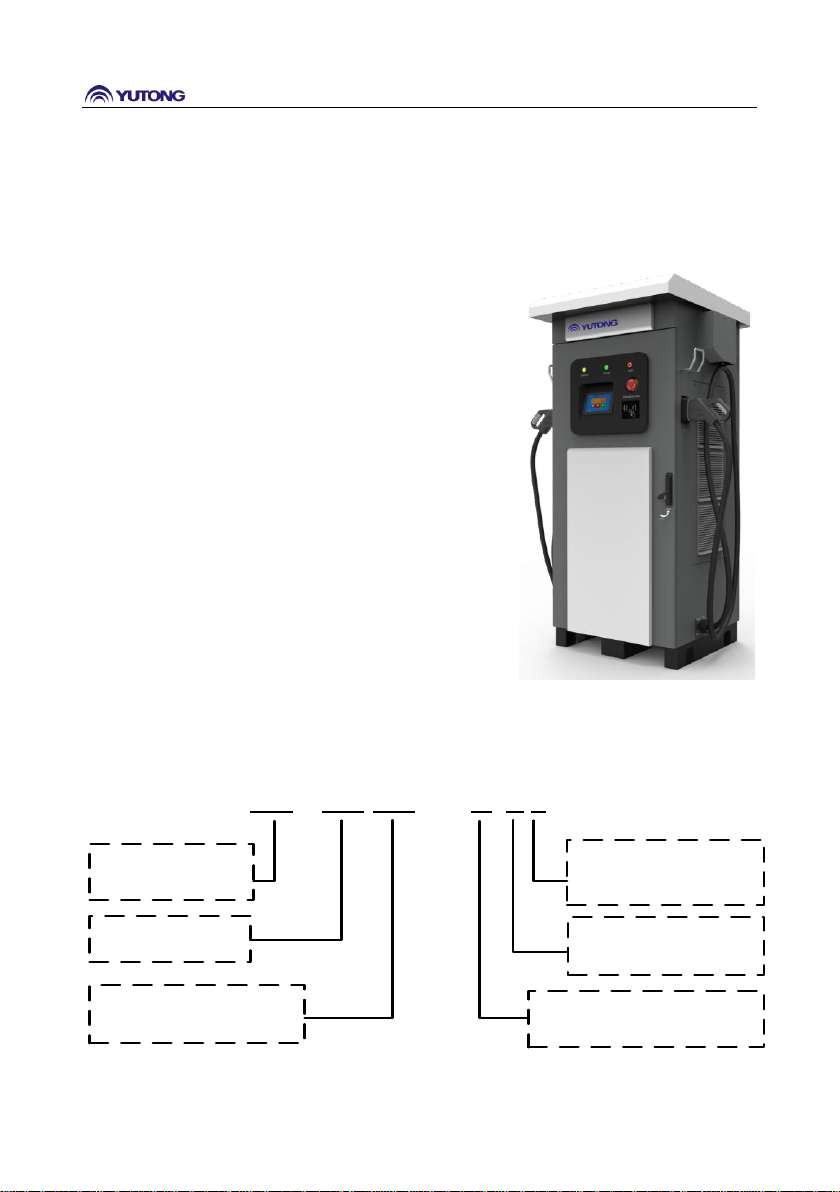

1.1 PRODUCT INTRODUCTION ...................................................................................... 1

1.2 PRODUCT MODEL ................................................................................................ 1

2. PRODUCT MODEL SPECIFICATION ............................................................ 2

3. NORMATIVE REFERENCE AND SPECIFICATION....................................... 3

4. ENVIRONMENTAL CONDITIONS................................................................ 4

5. ELECTRIC CHARACTERISTICS...................................................................... 4

5.1 INPUT CHARACTERISTICS ........................................................................................ 4

5.2 OUTPUT CHARACTERISTICS..................................................................................... 5

5.3 PROTECTION CHARACTERISTICS ............................................................................... 6

5.4 EMC CHARACTERISTICS ......................................................................................... 7

5.5 SAFETY FEATURES ................................................................................................. 8

5.6 OTHER CHARACTERISTICS ....................................................................................... 9

5.7 INDICATOR LIGHT................................................................................................ 10

6. PRODUCT CHARACTERISTICS................................................................... 10

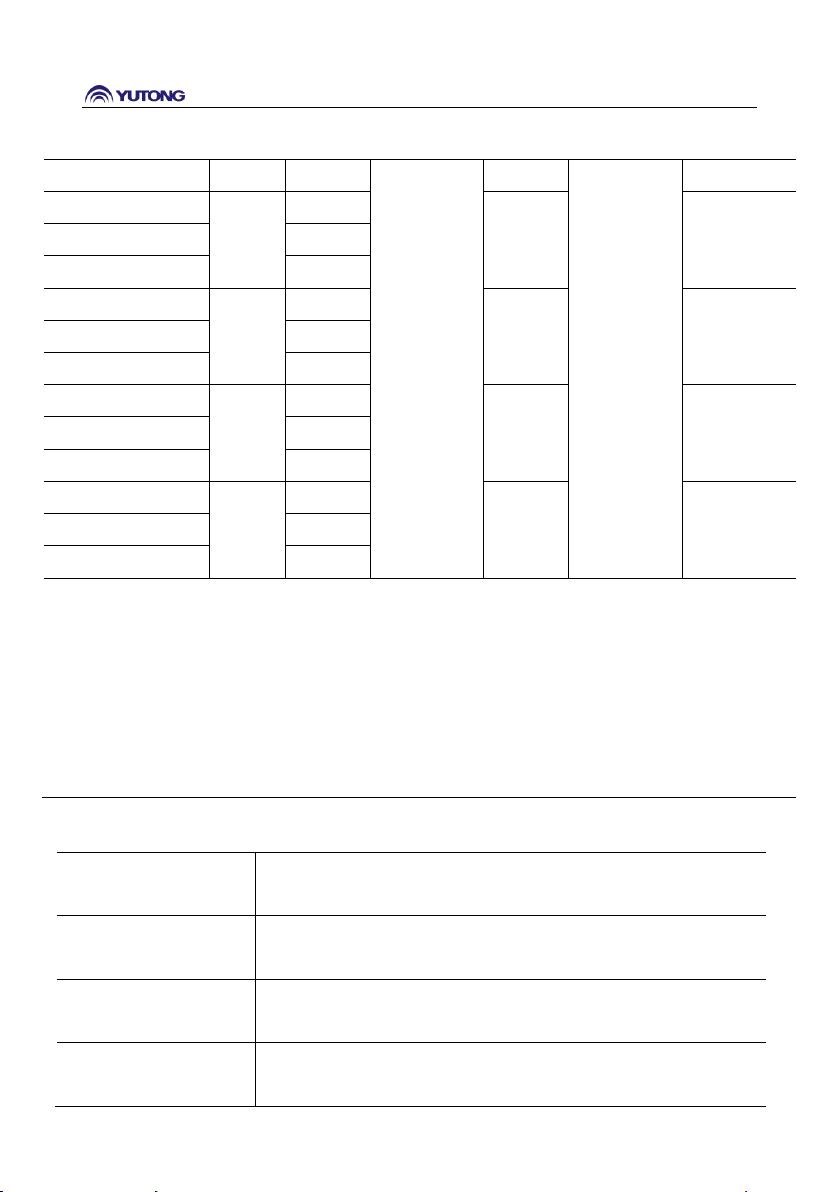

7. DIMENSION AND INSTALLATION............................................................ 11

7.1 DIMENSIONS ..................................................................................................... 11

7.2 INSTALLATION METHOD AND INSTALLATION HOLE SIZE .............................................. 12

8. POWER DISTRIBUTION.............................................................................. 16

8.1 INPUT AC POWER DISTRIBUTION WIRING .............................................................. 16

8.2 OUTPUT DC VEHICLE CONNECTOR PLUG PIN DEFINITION .......................................... 17

9. OPERATION INSTRUCTION ....................................................................... 18

9.1 CHECKS BEFORE CHARGING .................................................................................. 18

9.1.1 Safe checking before charging ............................................................... 18

9.1.2 Attentions in Operation Process............................................................. 18

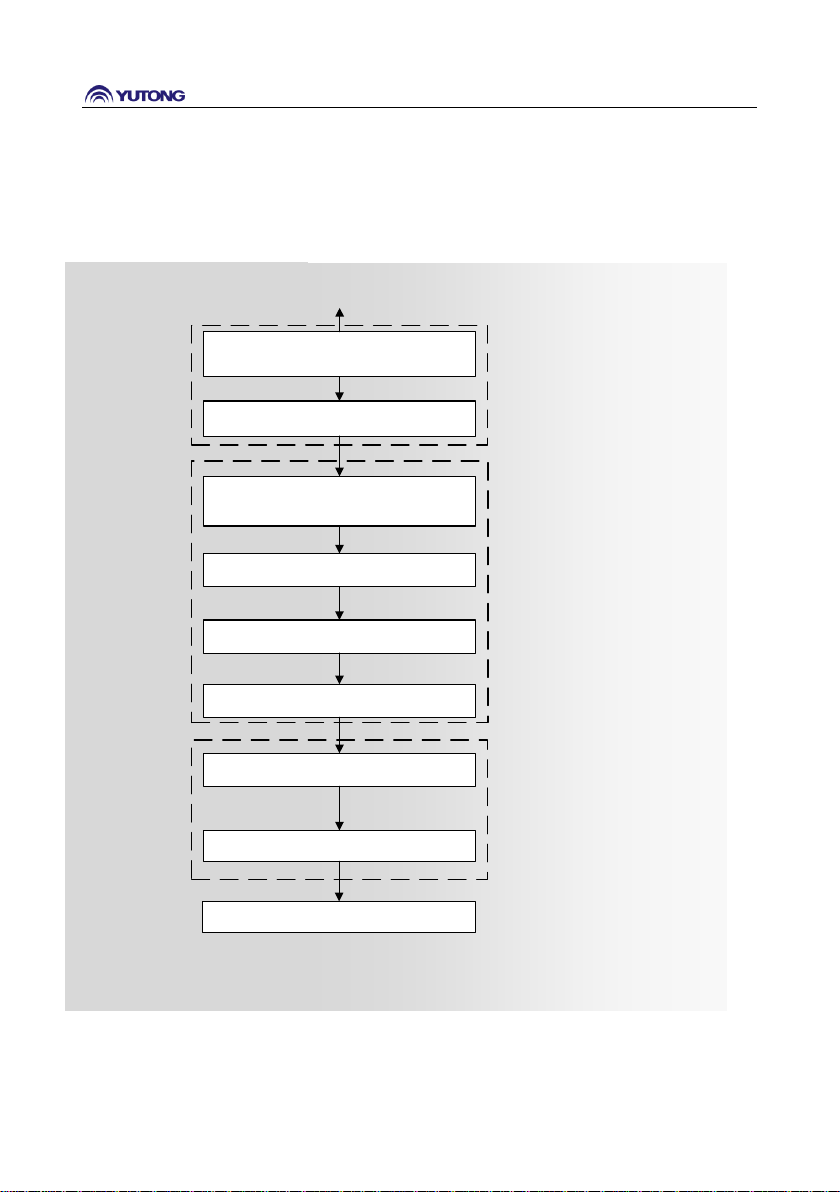

9.2 CHARGING OPERATION FLOW CHART ..................................................................... 19

9.3 CHARGING OPERATION DESCRIPTION ..................................................................... 20