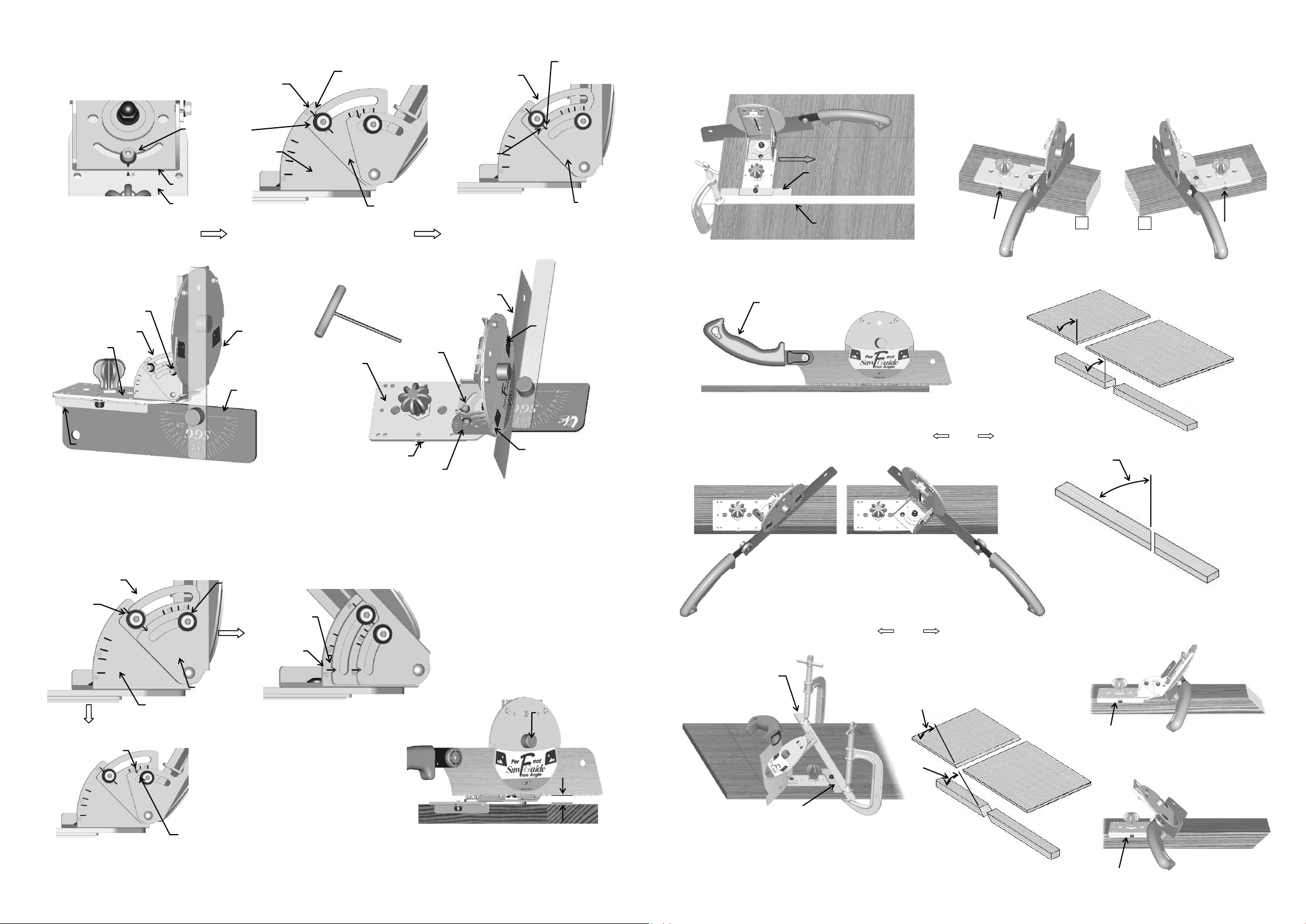

Set the positioning holder. Adjust the saw

guide gauge at 90°. Then, set it along with

base plate & saw guide plate. Make final

angle adjustment and fix with hex screw.

Set the positioning holder. Insert the

dummy plate into the saw guide plates Set

the saw guide gauge along with positioning

holder & dummy plate. Make final angle

adjustment and fix with hex screws.

Loosen screw 2. Set the matching mark of

bracket 3 on the 60°of bracket 2. Then fix

saw guide gauge at 60°and set it along with

positioning holder & saw guide plates.

Make final angle adjustment and fix firmly.

Loosen screw 1 first. Set the matching mark

of bracket 2 on the 45°angle of bracket 1 an

fix it. Set the saw guide gauge 45°and set it

along with base & saw guide plate like

illustration 1. Make final angle adjustment and

fix with hex screw.

Insert saw blade into the gap between guide

plates, then loosen height adjustment knob

slightly. Recommended clearance between the

surface of cutting object and the saw blade

teeth is approx. 6-8mm (1/4-5/16”). Then fix the

height of saw guide plates.

45°angle adjustment example

Compound angle adjustment

60°angle adjustment example

Variation of “Saw Guide, Free Angle”

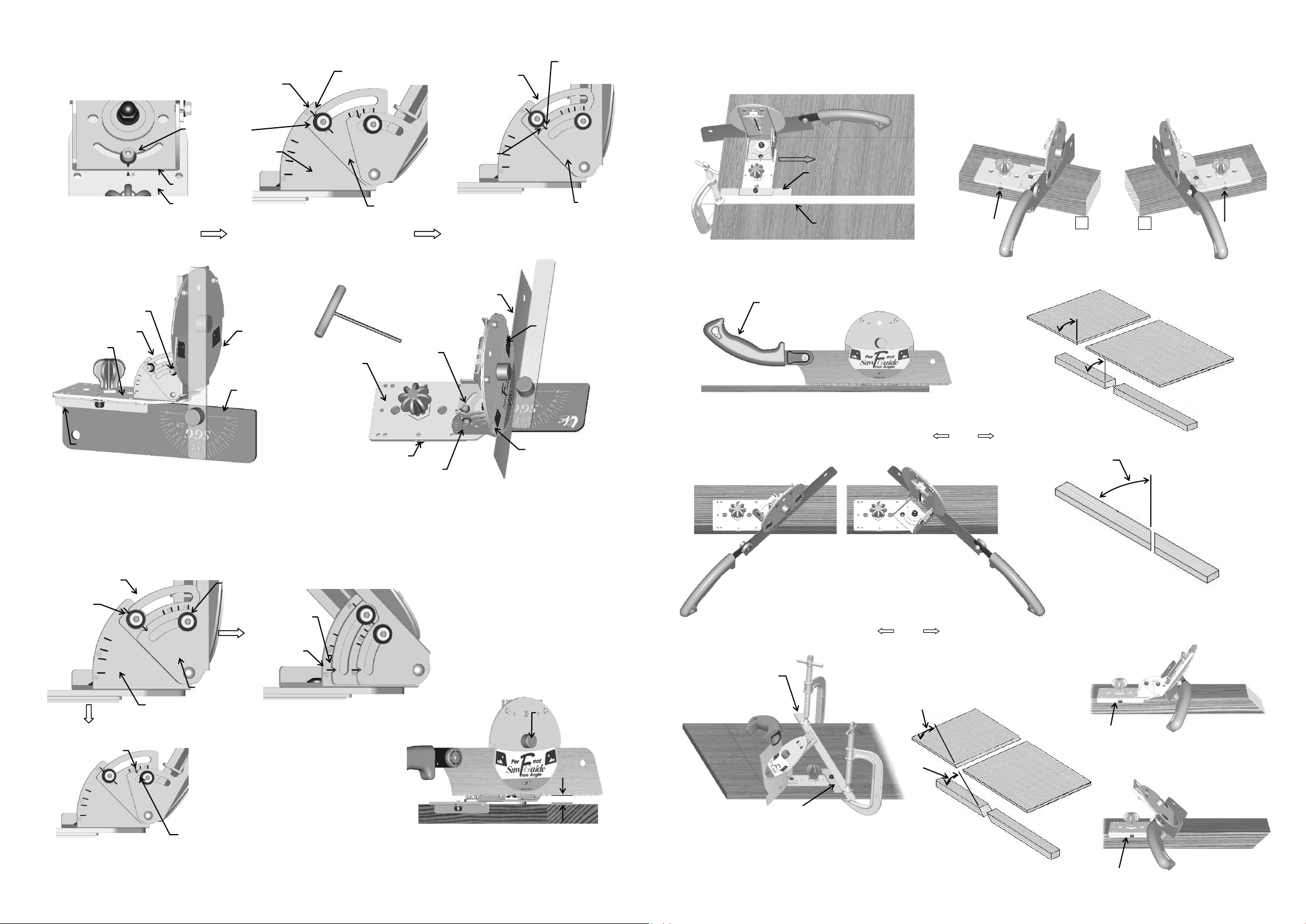

Compound cutting 45°90°45°

Right & Left angle cutting 45°90°45°

Too tight hinge connection between angle bracket and base plate may

loosen by applying some lubricants on pivots.

Match the triangle marks on the

angle bracket & the base plate.

Then, fix with hex screw.

Set the matching mark of Bracket 2

on thelineof90°angle of bracket1.

Then fix it.

Set the matching mark of Bracket 3 on

the line of 90°angle of bracket 2 Then

tighten slightly.

Handle can be reversed to provide hand clearance.

Illustration A shows right-handed use

and B is for left-handed.

When cutting square lumber, hold

the saw guide in a position firmly

by hand with positioning holder.

For cutting wide board, clamp rule or straight

wooden piece. Set parallel sliding holder along

the rule, then start sawing slowly by moving

the saw guide backward.

When cutting square lumber, hold

the saw guide in a position firmly

by hand with positioning holder.

For cutting wide board, clamp rule or straight

wooden piece. Set parallel sliding holder along

the rule, then start sawing slowly by moving the

saw guide backward.

When cutting square lumber, hold

the saw guide in a position firmly

by hand with positioning holder.