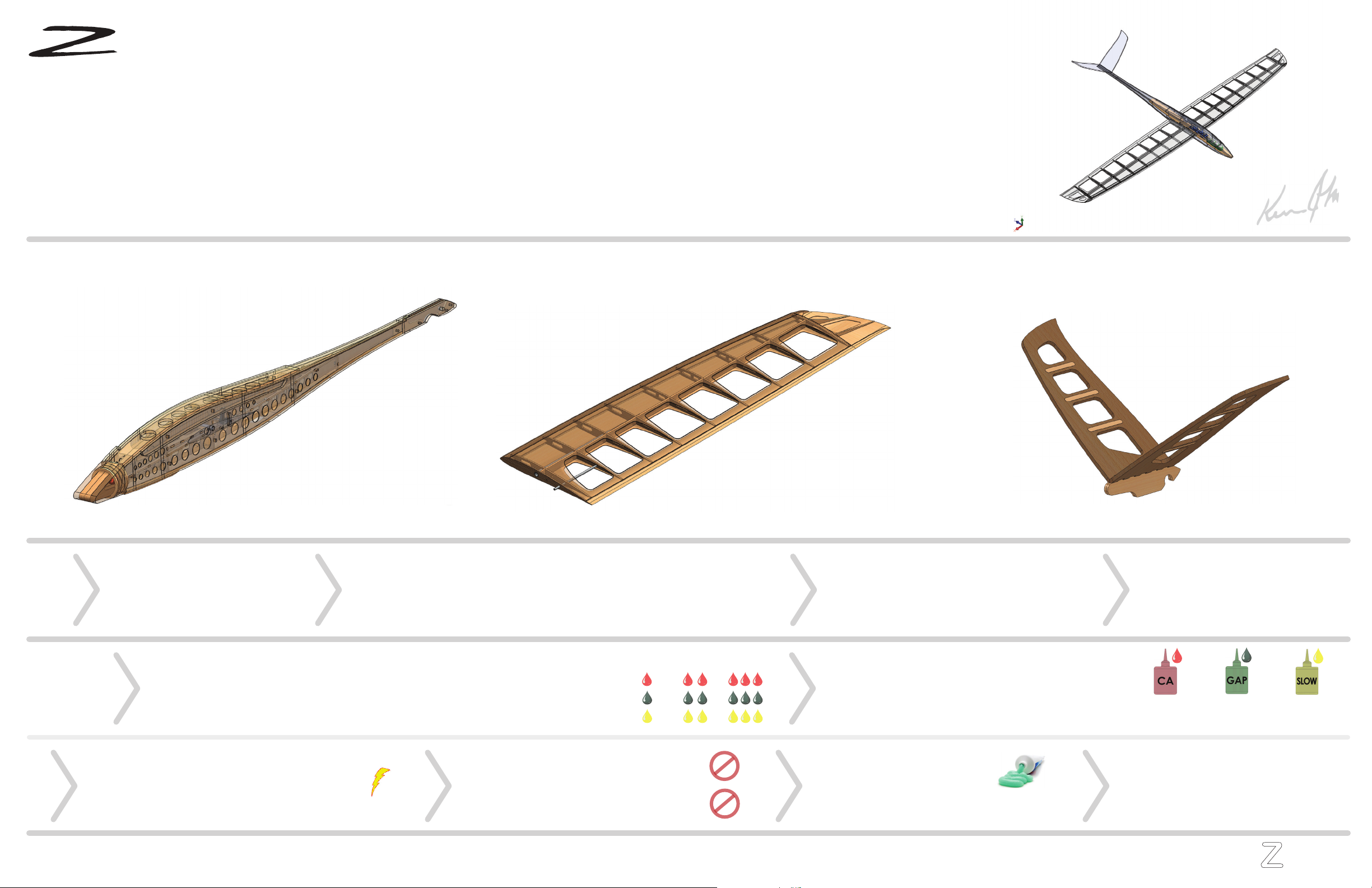

Accelerator

Accelerator

Tail Angle

v2

33

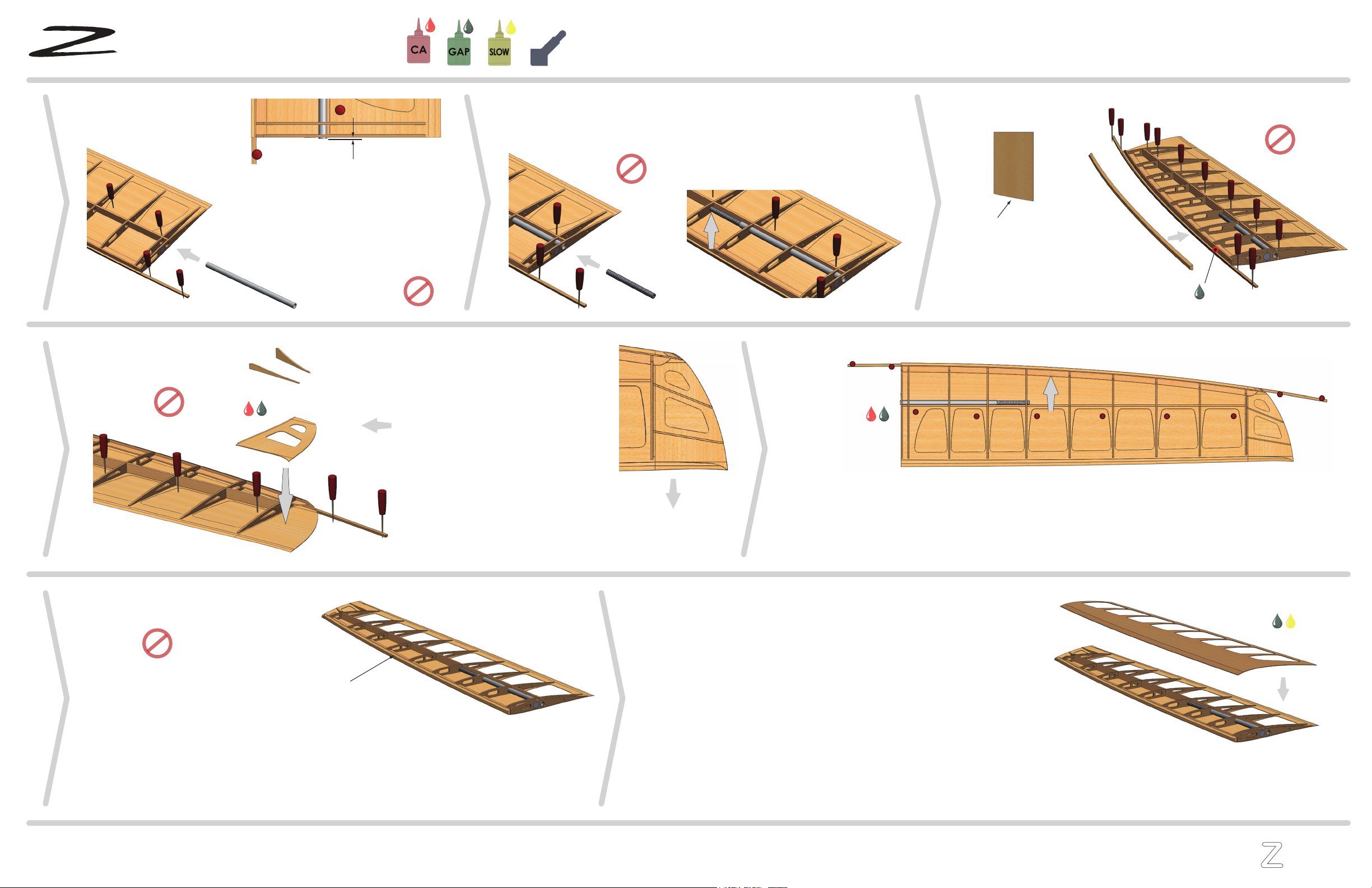

Tail Construction 1

aerotech

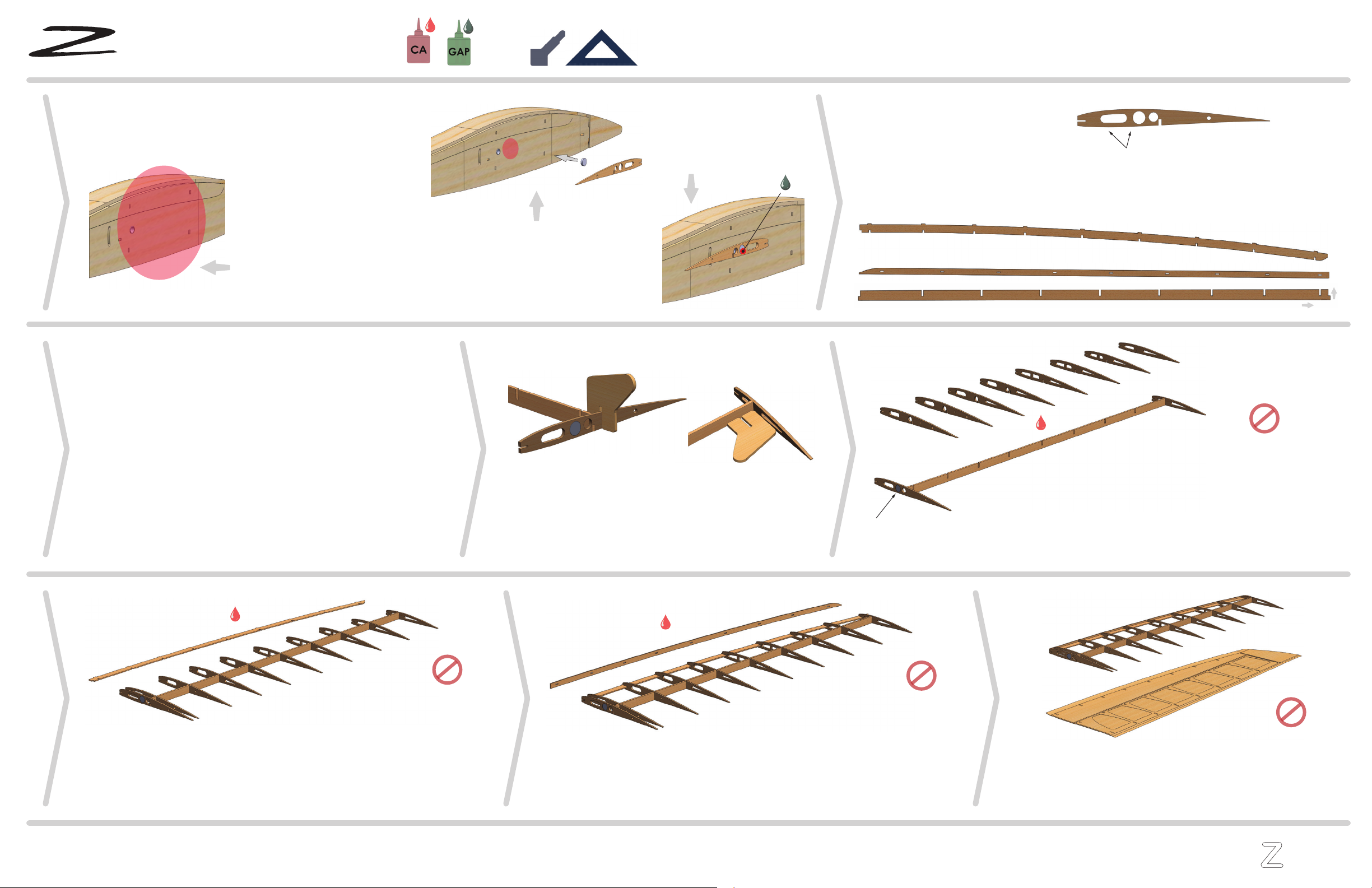

Now notice when you view it from behind, the rear cross-brace

carries the Stab angle. You will reference these aids while sand-

ing and adjusting the tabs on the Stab, until you obtain a snug

tab fit and alignment

Carefully fit the Stab and Blade tabs together and let the Stab rest on the Multi-Jig. Check the two angles described above. If

the side rail angle is off, you’ll need to favor either the foreward or aft end of the angle you sanded, effectively tilting the Stab.

The tail angle should be off naturally, requiring you to sand the angle more, effectively moving the Stab down. Take your time,

as this alignment is critical. There is no tail trim on a pitcheron, so tracking is as good as your work. When you get the angle

set, sand the second angle from the tabs so the right stab can be fit. Approximate this angle on the right Stab before fitting

Lightly sand the two Tail Blades on a flat surface with 400

grit sandpaper. Then take a small round object, wrap 400+

grit sandpaper around it, and very lightly sand the capture

radius. Now lightly sand each part, and remove any sharp

edges below the indexing tabs. The tabs will get sanded

later, so no need to prepare them

Capture Radius

The basic theory behind the tail capture design is simple, but it is very

important that you follow the methods here to ensure proper operation.

The wood will cut the O-Rings if engaged before preparation, so take

your time.

Stab Preparation:

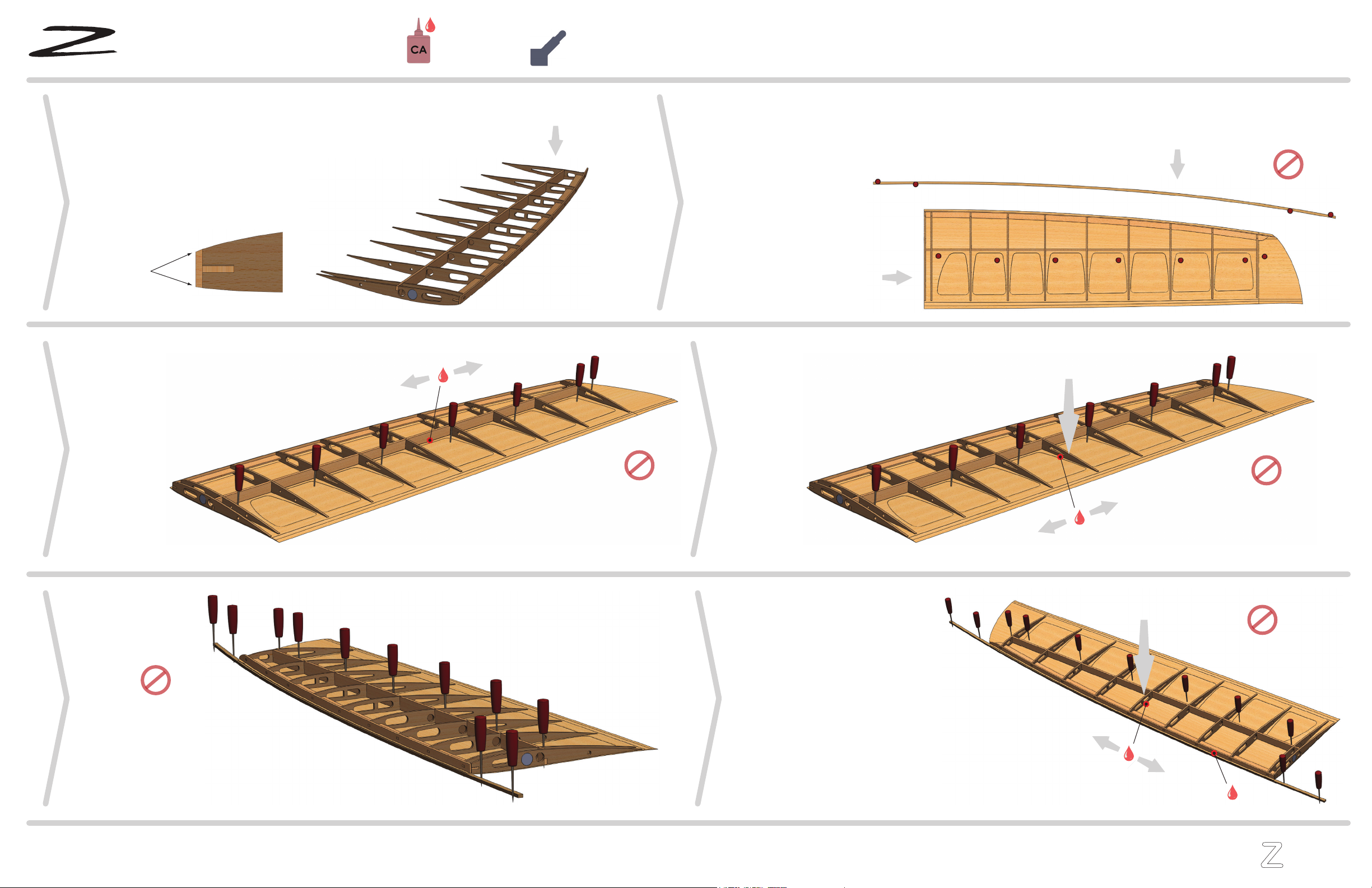

Bonding and Finish:Tack the Stabs In-place:

Alignment & Fit:

Slip the foreward end of the Blades into the Tail cavity as

illustrated. The fit should be snug, but not overly tight.

Rotate the aft end down, and stop before you engage the

O-Rings. Again, only snug, but easy to push in and extract

If too tight, sand the blades on a flat surface until they slip

in snug

Tail Blade Preparation:

Locate;

- (2)x 1.5mm Ply Tail Blade

Sand each Blade

face to completely

flush the surface to

the Stab tabs. Then

sand the Blade

tabs flush with the

top surface of the

Stab. Finish sand

the entire interface

When you are satisfied with Blades fit, rub a little candle wax on the edge of the Capture Radius. A very small

amount is enough. Rub it in, and remove any excess. Adhesive will not stick to wax, so don’t spread it beyond

the edge of the radius that will engage the O-Rings

Gently rotate the Blades down with your thumb, and apply a little foreward pressure when you feel resistance.

You should feel the capture engaging, and with a little extra pressure, slip home. The top plane of the Blades

should now be parallel to the top plane of the Tail. If not, check for adhesive, debris, sharp corners on the Blade,

etc. You can also sand the capture radius slightly, to move the center up, or to loosen it a bit. But more than

0.5mm in any direction means there is problem elsewhere. To release, apply pressure with your index finger

Stab Bonding:

Tail Latch Theory:

Indexing Tab

Make sure the Tail cavity is clean, and void of any

excess adhesive. Then proceed to the next step

Blade Fitting:

Tail Spline Installation:

Before you remove the Tail parts from the sheet, notice that there

is the side with markings (Cut Side), and a side with laser flash

scorching

Fit the Balsa Spines in their respective holes, with the Stabs “Cut

side” up, and the Spines flashed side up. The laser cuts with a very

slight taper. Flipping the Splines will help the fitting. When flush,

dab some adhesive into the joint

You will be sanding two angles on the index-

ing tab end of each Stab. The first of these

angles (37.5 degrees), illustrated above in

gray, will allow you to set the incidence and

tracking of each stab. You will fit the left

Stab first, and set the alignment as

described in the next step. The second angle

will be sanded in-process to the fit

DO NOT TEST ENGAGE

Bottom

Use only thicker viscosity adhesive for this operation

Above the intersection of each Blade tab, apply one

drop of adhesive where the Stab contacts it

Do this for each tab, then check to make sure you did

not spread adhesive to the opposite Blade

Repeat with the right Stab. Let them cure, then remove

them by using your index finger to eject the tail

Notice by moving the

Multi-Jig fore and aft, you’ll

find a spot where the Stab

will fully fit between the

uprights of the horizontal

rail. Set up the Multi-Jig

and fuselage on a flat

surface and ensure that the

structure is still straight

and not twisted

37.5

Apply adhesive to the entire interface.

CA or thin epoxy works best to

penetrate the tabs

Add a fillet of adhesive to

the underside interface

Filled epoxy works best.

Alternately SLOW cyano or

thickened wood resin. An

adequate fillet is essential

to a reliable joint

Finish sand both Stabs. Radius the leading edge, and taper the trailing

edge to achieve a smooth surface. Sand as far as you see fit, but leave

at least a 1mm trailing edge thickness for strength

Adhesive

Adhesive

Adhesive

Horz. Rail

Sand Faces

O

Second angle needs to be

sanded before tacking