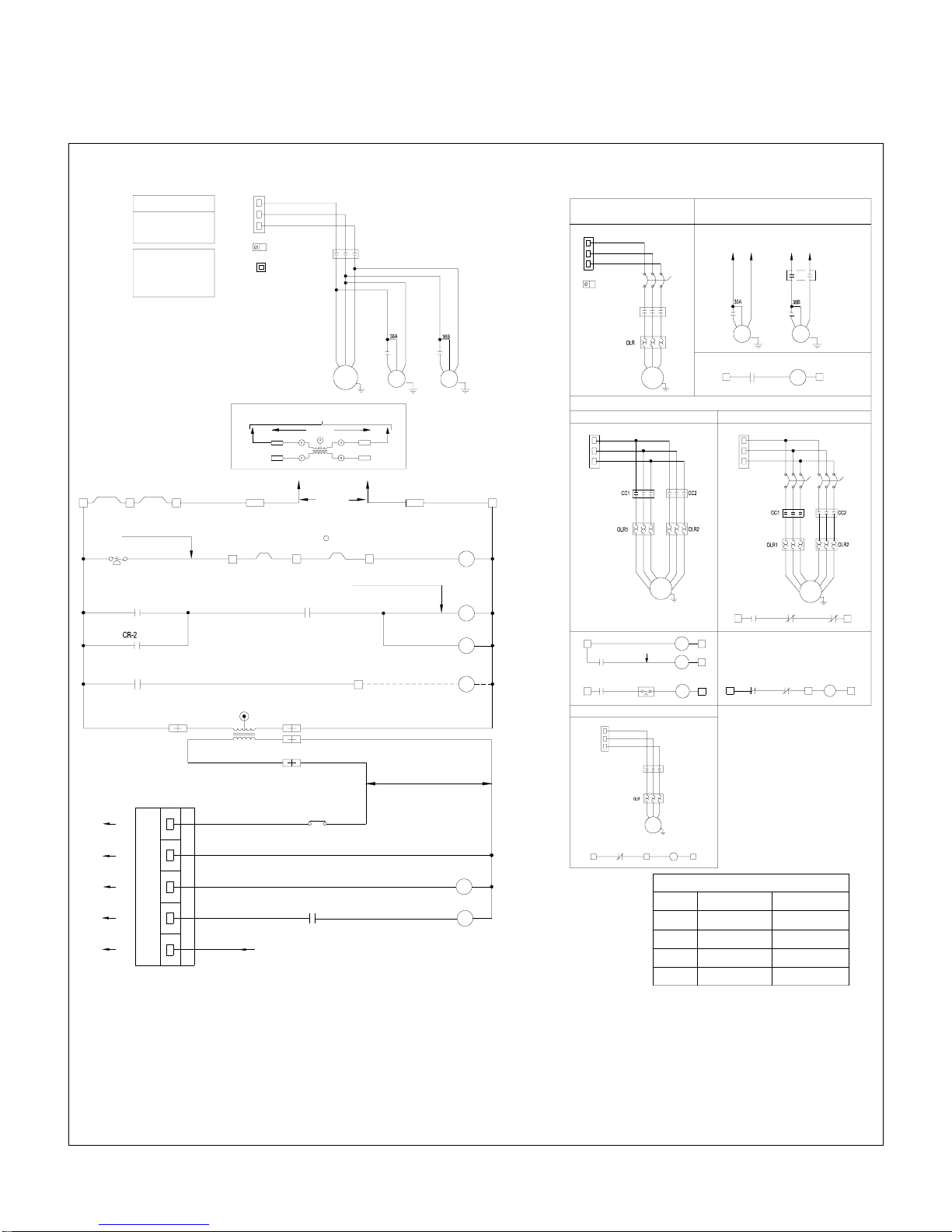

1& 2

BASIC 3, 4 & 5

NOMINAL

COOLING

CAPACITY

(MBH)

7

REFRIGERA-

TION CIRCUIT

6

ELECTRICAL

SUPPLY

( V-Ph-Hz )

9

MODE 11

CONDENSER

COIL

CX

CLASSIC

CONDENSING

UNIT

150

180

220

240

300

360

S: SINGLE*

D: DUAL

H: 208/230-3-60

M: 380-3-60

(4 WIRE)

F : 460-3-60

C: COOL ONLY

H: HEAT PUMP+

A:ALUMINUM

FIN

B: COATED

ALUMINUM

FIN

C:COPPER FIN

MODEL DECODING

8

COMPRESSOR

TYPE

S: SCROLL

13

OTHER OPTIONS

10

CONDENSER

MOTOR

N: STANDARD

L: LOW

AMBIENT

12

PDS OPTION

N: NO OPTION

F: STD. UNIT WITH

FILTER DRYER

& SIGHT GLASS

K:

CONDENSING

UNIT WITH

SYSTEMIZER

**

P: PDS***

R :F&K

S :F&P***

T :K&P***

Q : F, K & P***

N: NO OPTION

U: UVM

V: VOLT FREE

CONTACTS

C: U & V

*Applicable for CX150 only.

** To match with double skin units only.

*** Applicable for cool only models.

+Applicable for CX150 to CX220 only. GENERAL STATEMENT

These units are from the Classic CX series that was designed and built for the optimum performance when matched with the

right indoor unit (Refer to indoor unit catalog). However, it is required that you become well acquainted with good practices for

the proper installation, operation, and maintenance procedures in order to ensure a safe trouble free operation, year after year.

Mostof theproceduresdescribedinthis manualrequire certainskills andexperience. Onlyhighly skilledand experienced

technicians should perform the installation and other maintenance procedures.

WARRANTY

All of the Classic CX series are covered by the standard warranty terms against any manufacturer defect. Should you

encounteranyproblemthat fallsunder thewarrantytermspleasecontact yournearest “ZamilClassic” dealer/representative.

SAFETY ISSUES

There are three levels of safety hazards that are identified throughout this manual as Warning (where the situation will

result in personal injury), Caution (where personal injury might occur), and Attention (where minor personal injury and/or

property damage could happen). Please understand and respect those identifications.

WARNING: These units operate on a high voltage with moving parts (at high speed) which can lead to

serious injuries and/or damage to the unit. Never attempt to service the unit unless the main electrical power

supply has been disconnected.

CAUTION: Extra care should be observed when installing, test running, adjusting, servicing, or maintaining

the unit as the hazard of explosion, fire, electrical shock, and potential personal injury and property damage

are present.

When performing any task pertaining to the installation and maintenance of the unit, the skilled technician should observe

all the applicable safety measures (wear of safety helmet, boots, and goggles. Use of proper handling materials for

brazing and use of wet cloth for sequencing. A fire extinguisher should be easily accessible etc). He should also read all

the instructions and information in this manual prior to attempting to perform any installation or servicing of the unit.

All applicable local codes should be observed during installation and servicing.

INSPECTION FOR DAMAGE

The unit should be carefully inspected visually for any sign of physical damage due to mishandling or missing parts. If

such a case arises, please indicate it on the corresponding delivery note before sign it and inform your nearest “Zamil

Classic” dealer and/or sales office.

2