Contents Page

Model decoding ........................................................................................................................................ 2

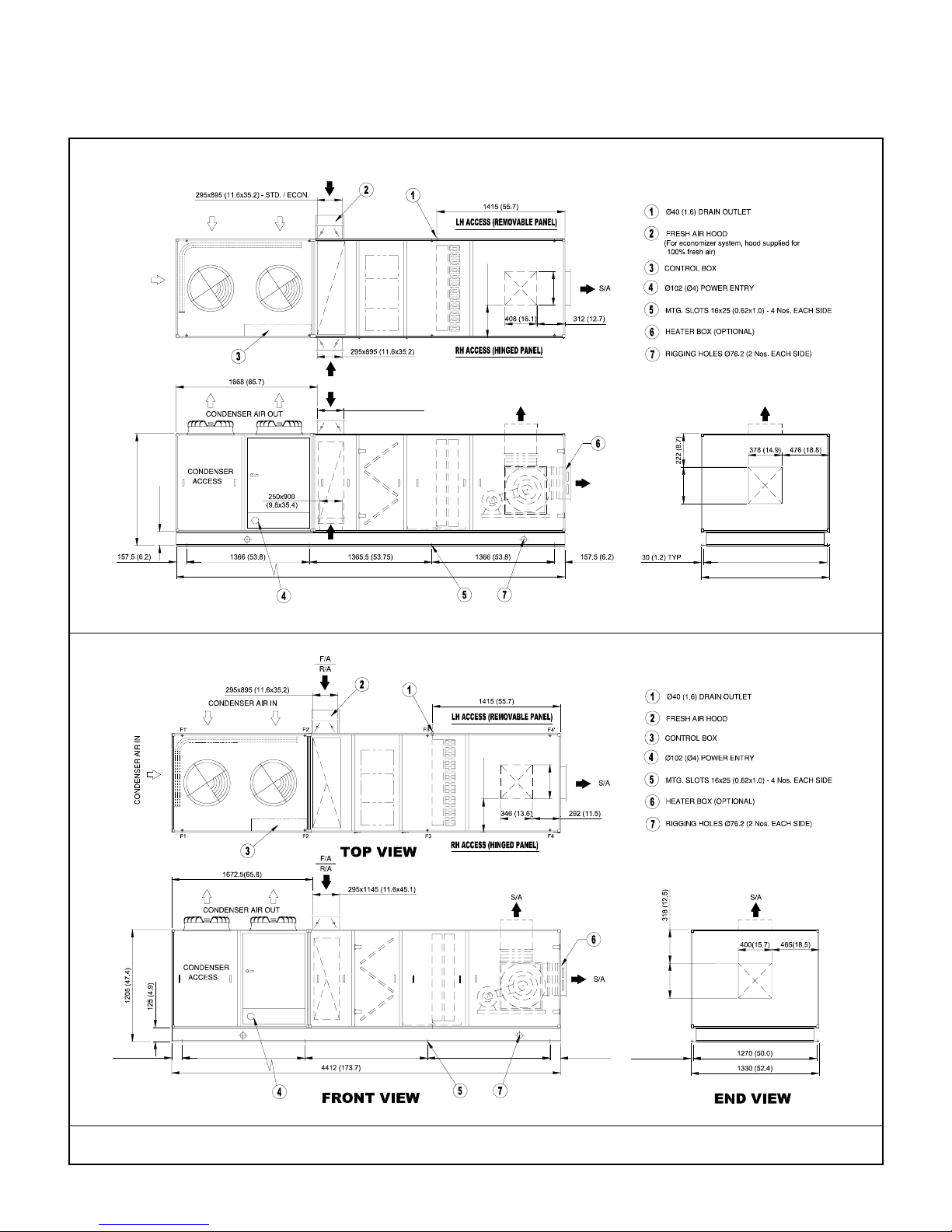

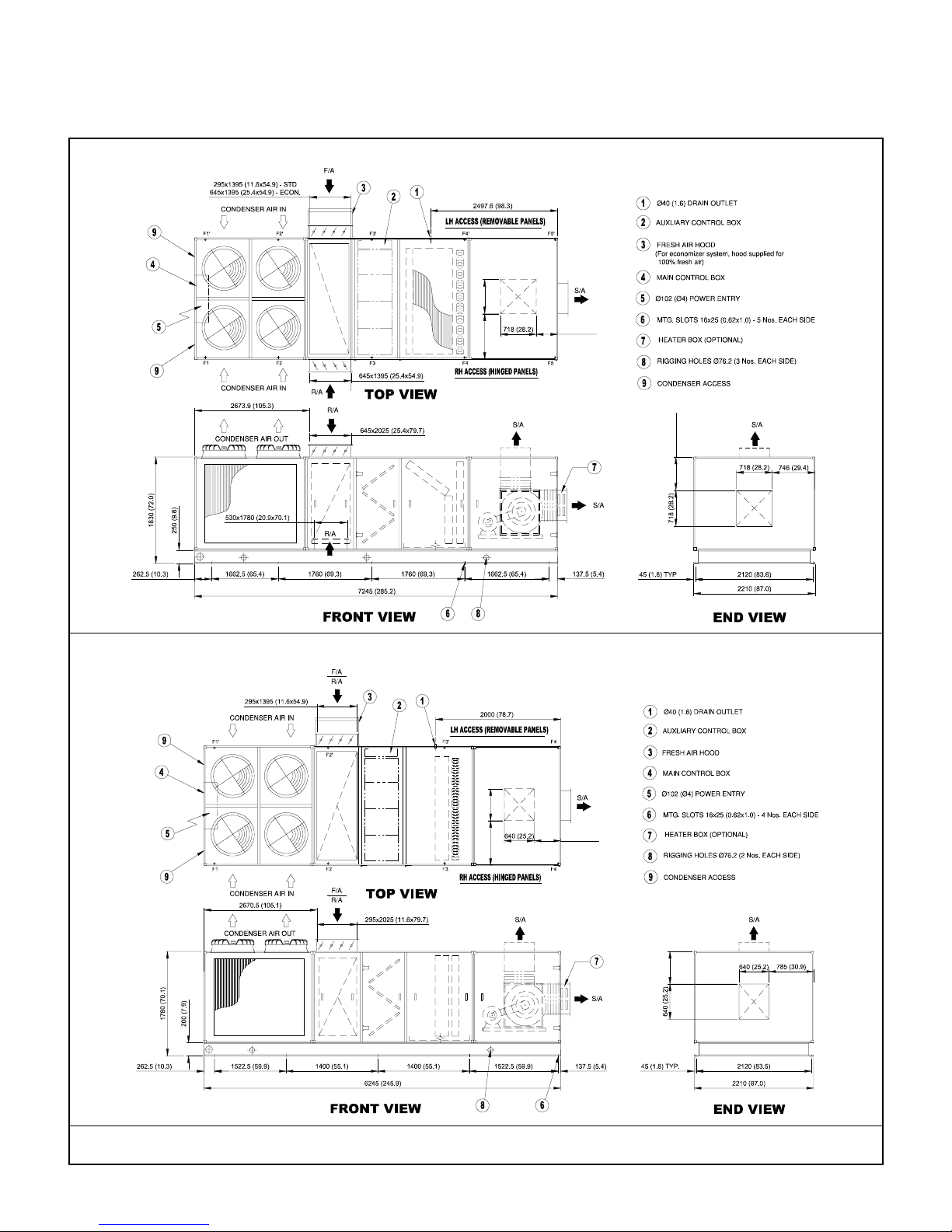

Dimensions.......................................................................................................................................... 3-10

Fresh air hood assembly ........................................................................................................................ 11

Rigging instructions ................................................................................................................................ 12

Installation .............................................................................................................................................. 13

Typical schematic wiring diagram...................................................................................................... 14-19

INSTALLATION INSTRUCTIONS

General................................................................................................................................................... 20

Location of unit ....................................................................................................................................... 20

Wiring ..................................................................................................................................................... 20

Start-up inspection & check list ......................................................................................................... 20-21

Check-out & operational start-up procedure ...................................................................................... 21-22

Belt tension testing procedure ........................................................................................................... 22-23

ELECTRICAL

Power supply .......................................................................................................................................... 24

Unbalanced voltage ................................................................................................................................ 24

Motor contactor ...................................................................................................................................... 25

Fan motor ............................................................................................................................................... 25

Crankcase heater ................................................................................................................................... 25

Lube oil protection control ................................................................................................................. 25-26

Voltage monitor ...................................................................................................................................... 26

Electronic thermostat ........................................................................................................................ 26-27

REFRIGERATION

Compressor ............................................................................................................................................ 28

High & low pressure switch .................................................................................................................... 29

Pump down control................................................................................................................................. 30

Trouble shooting chart ....................................................................................................................... 31-33

Parts list ............................................................................................................................................ 34-40

Recommended spare parts .................................................................................................................... 41

Preventive maintenance schedule.......................................................................................................... 42

INDEX

CONTINUING RESEARCH RESULTS IN STEADY IMPROVEMENTS.

THEREFORE, THESE SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

1