12 ZANOTTI S.p.A.

AS

R

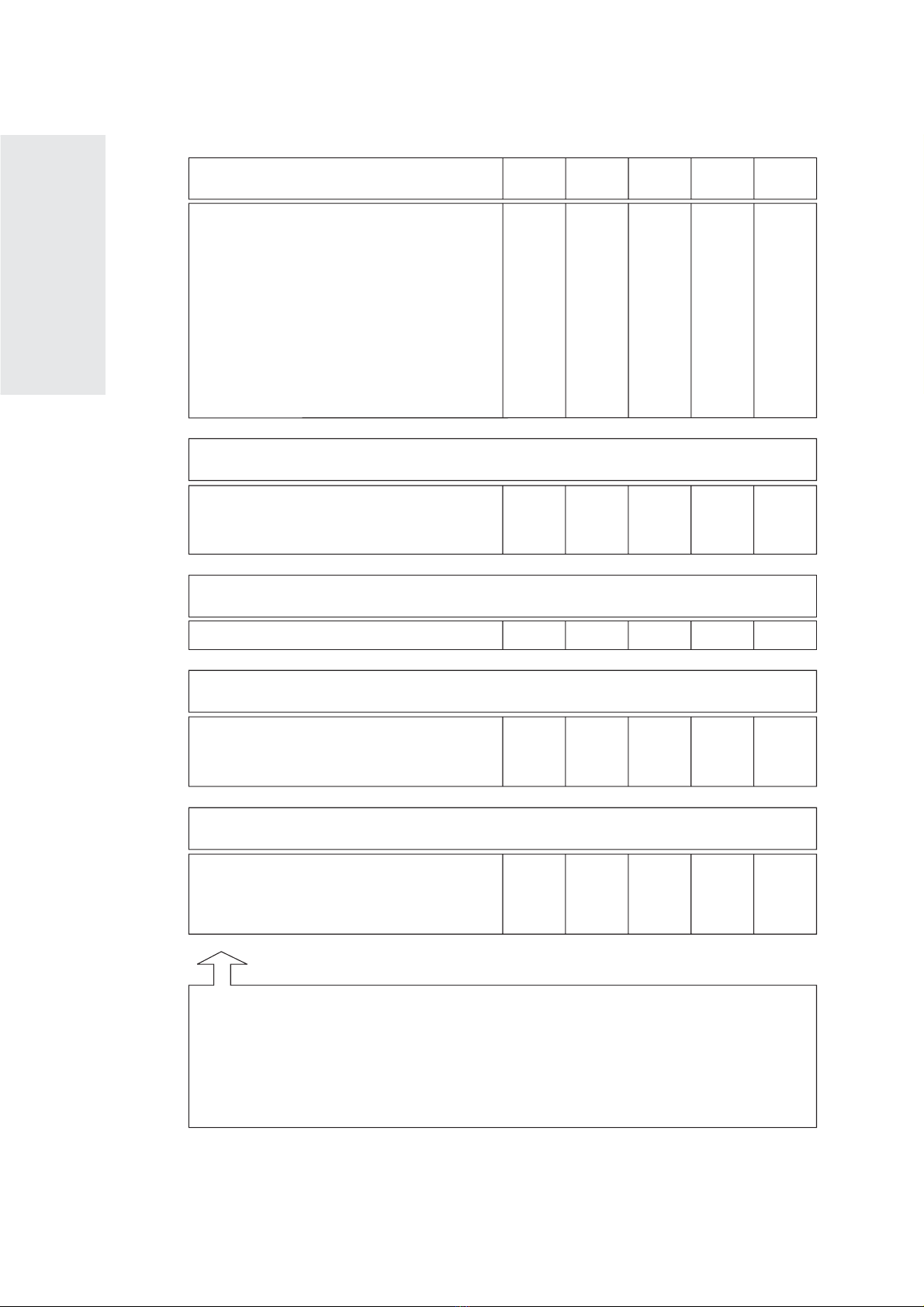

230/1~/50 230/1~/50 230/1~/50

0,5 0,6 1,1

3,4 3,7 6,7

R407C R407C R407C

GGG

53 57 77

E= Comp. ermetico - Hermetic comp. - Comp. hermétique - Hermetischer Komp. - Comp. hermético

G= Gas Caldo - Hot gas - Gaz chaud - Heissgas - gas caliente

*= In condizioni di marcia - When normally running - En marche - Bei Betrieb - En funcionamiento

** = Utilizzare come indicazione. La freccia daria é dipendente da numerosi fattori; altezza cella, stoccaggio del prodotto, posizionamento dellevaporatore, etc..

Indicative. Air throw depends on different factors, such as: room height, storage method, evaporator location, etc.

Utiliser à titre indicatif. La projection dair dépend de nombreux facteurs: hauteur de la chambre, type de stockage, positionnement de lévaporateur, etc.

Zur Bemerkung. Luftwurf ist von zahlreichen Faktoren abhängig: Kühlzellenhöhe, Lagerungstyp, Verdampferstellung, usw.

Utilizar como se indica. La proyección del aire depende de numerosos factores: altura de la cámara, almacenamiento del producto, posición del evap.,etc.

ensione - Voltage - ension

Spannung - Voltaje

Assorb. nominale - Rated input - Absorp. nominale

Nennaufnahme - Absorción nominal

Assorb. nominale - Rated input - Absorp. nominale

Nennaufnahme - Absorción nominal

Refrigerante - Refrigerant - Réfrigérant

Kältemittel - Refrigerante

Sbrinamento - Defrost - Dégivrage

Abtauung - Descarche

Massa - Mass - Masse - Masse - Masa

Volt-Ph-Hz

kW*

AMP

Kg

Codice - Code - Code

Code - Código MAS121

118S

MAS123

118S

MAS221

N118S

kW

ipo - ype - ype

yp - ipo

Pot. nom. - Rated output - Puissance nominale

Nennleistung- Potencia Nominal

Compressore - Compressor - Compresseur - Kompressor - Compresor

Potenza frigorifera - Refr.capacity - Puissance frig.

Kälteleistung - Potencia frigorífica

Volume di cella consigliato - Suggested room volume

Volume chambre conseillé - Empf. Kühlzellevolumen

Volumen cámara aconsejado

Watt

Scelta rapida - Quick selection - Sélection rapide - Schnellauswahl - Selección rápida

m**

Dati tecnici - echnical data - Données techniques

echnische Daten- Datos técnicos

Portata d aria - Air flow - Débit dair

Luftmenge - Capacidad aire m

3

/h

Condensatore - Condenser - Condenseur - Kondensator - Condensador

700 700 1400

Portata d aria - Air flow - Débit dair

Luftmenge - Capacidad aire

Freccia daria - Air throw - Projection dair

Luftwurf - Proyección aire

m

3

/h

m**

Evaporatore - Evaporator - Evaporateur - Verdampfer - Evaporador

600 600 1200

444

EEE

0,46 0,56 0,74

1100 1400 1900

51019