CARE AND CLEANING OF YOUR ELECTRONIC

MARKER

Always

follow

all safety rules when operating the marker.

Misuse

or

abuse

of

the marker can cause serious

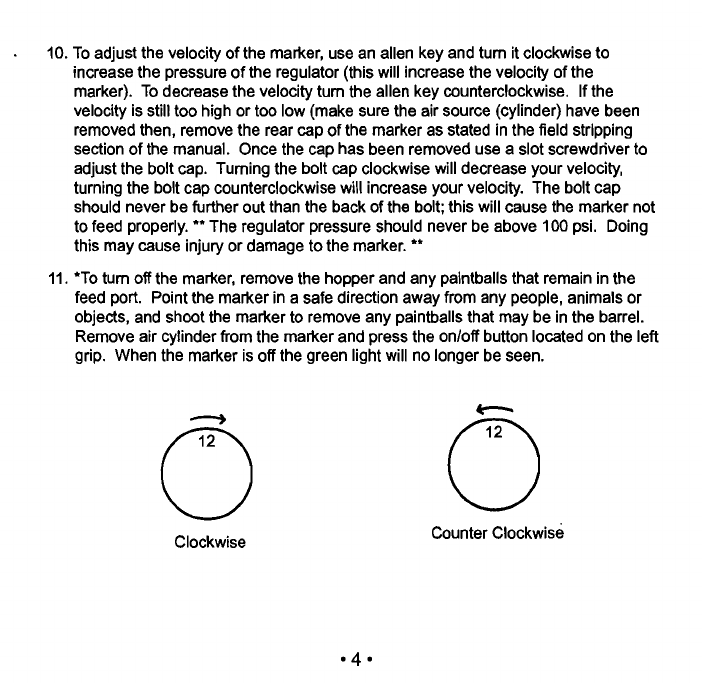

injury

or

death.

This marker contains delicate electronic parts

QQ.n.Q1

subject the marker

to

water

or

any other liquid that may destroy the electronic components.

Always remove air

source

(cylinder) before

disassembling the marker

Oiling your marker: The only components that require oil are the bolt o-rings. Use a

high grade, lightweight lubricating oil.

Cleaning: Always remove battery before cleaning marker.

To

clean your

barrel, remove itfrom the marker and rinse thoroughly with warm

water.

To

clean the body, wipe down with a damp cloth ensuring not to

get any water into the grip frame.

To

clean the Inside

of

the body, remove from grip frame as

outlined in the field stripping section

of

this manual. Rinse with

warm water and be sure

to

dry before reassembling marker.

To

clean the grips, remove them as outlined in the in the field

stripping section

of

this manual. Rinse with warm water and be

sure to dry completely before reassembling.

·8·