5. SAFETY AND OPERATION PRECAUTIONS

Because an air dryer is pressurized and contains rotating parts, the same precautions

should be observed as with any piece of machinery of this type where carelessness in

operation or maintenance could be hazardous to personnel. In addition to obvious safety

rules that should be followed with this type of machinery, safety precautions as listed

below must be observed:

1. Only qualified personnel shall be permitted to adjust,

perform maintenance or repair this air dryer.

2. Read all instructions completely before operating unit.

3. Pull main electrical disconnect switch and disconnect any

separate control lines, if used, before attempting to work

or perform maintenance on the unit.

4. Do not attempt to service any part while machine is in an

operational mode.

5. Do not attempt to remove any parts without first relieving

the entire air system of pressure.

6. Do not attempt to remove any part of the refrigeration

system without removing and containing refrigerant in

accordance with the EPA and local regulations.

7. Do not operate the dryer at pressures in excess of its

rating.

8. Do not operate the dryer without guards, shields and

screen in place.

9. Inspect unit daily to observe and correct any unsafe

operating conditions.

5

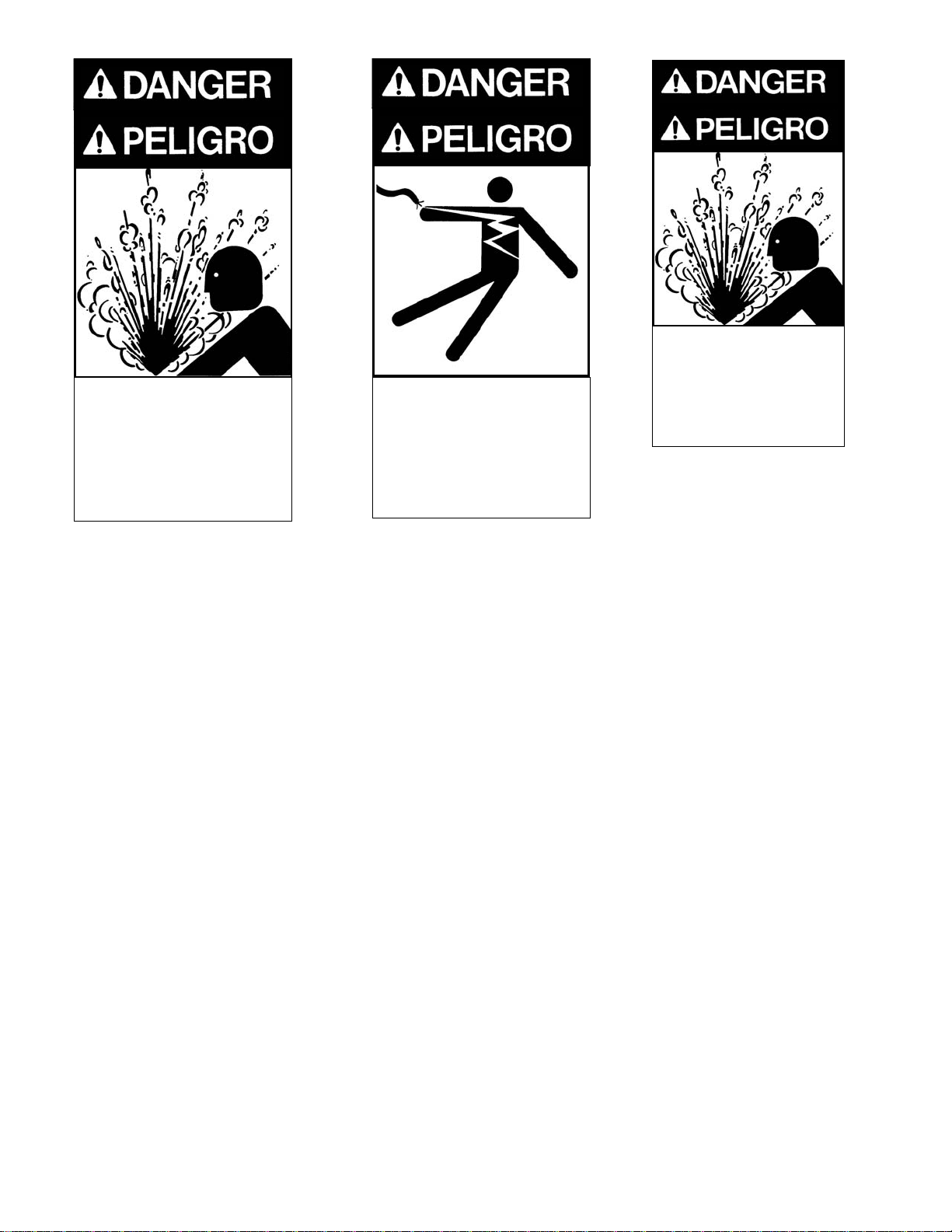

“WARNING” is used to indicate

a hazardous situation which

has some probability of death

or severe injury. Warning

should not be considered for

property damage accidents

unless personal injury risk is

present.

“NOTICE” is used to indicate a

statement of company policy

as the message relates directly

or indirectly to the safety of

personnel or protection of

property. Notice should not be

associated directly with a

hazard or hazardous situation

and must not be used in place

of “DANGER,” “WARNING,” or

“CAUTION.”

“CAUTION” is used to indicate

a hazardous situation which

may result in minor or

moderate injury.

NOTICE

CAUTION

NOTICE

WARNING

OSHA

Heading Descriptions

The user of any air dryer manufactured by ZEKS Compressed Air Solutions, is hereby

warned that failure to follow the above Safety and Operation Precautions may result

in personal injury or equipment damage. However, ZEKS Compressed Air Solutions

does not state as fact, nor does it mean to imply, that the preceding list of Safety and

Operating Precautions is all inclusive, and further, that the observance of this list will

prevent all personal injury or equipment damage.