1

Contents

1 About this operation manual ..........................................2

1.1 Zell hot-line

.......................................................2

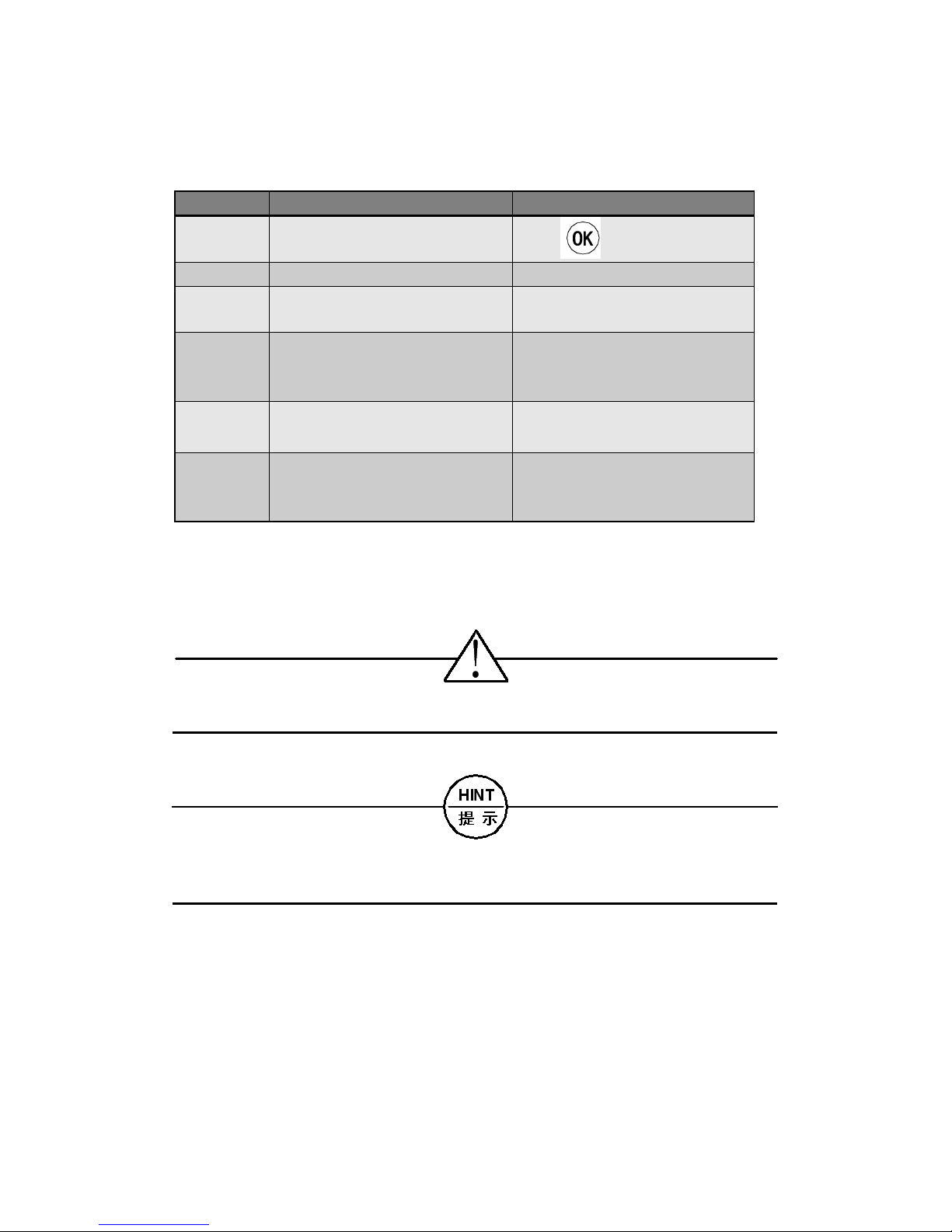

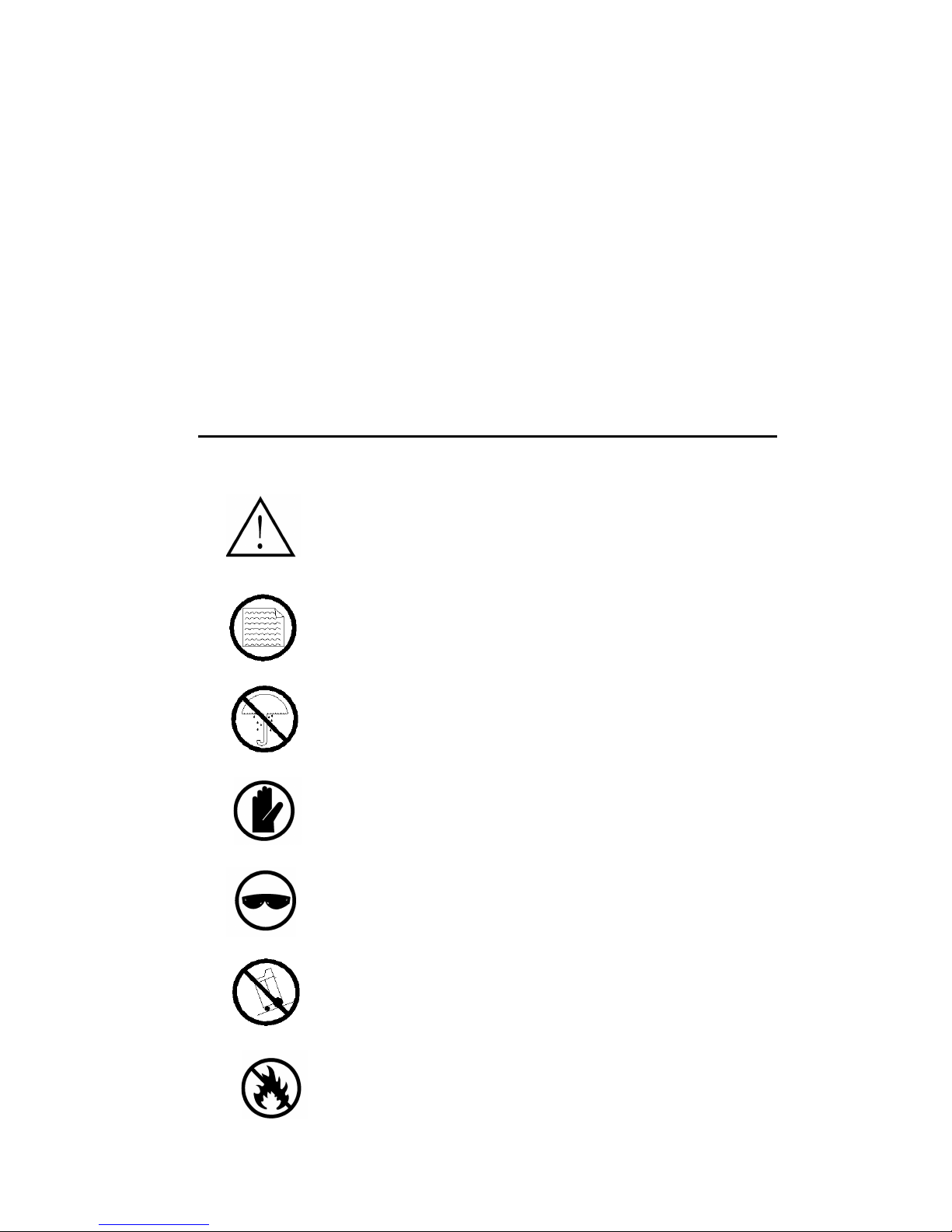

1.2 Explanation

of symbols in this operation manual ..........................3

2 Scope of delivery ...................................................4

3 Safety..............................................................5

3.1 General safety instructions

..............................................5

3.2 Warnings on the Air-Con Ser ice Station

..................................6

3.3 Safety de ices

..................................................... 7

4 Proper use..........................................................7

5 verview of the Air-Con Service Station .................................8

6 First start up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

6.1 Setting up and switch up

............................................... 11

6.2 Putting into the bottles for new oil

....................................12

6.3 Filling up the internal refrigerant container

.................................12

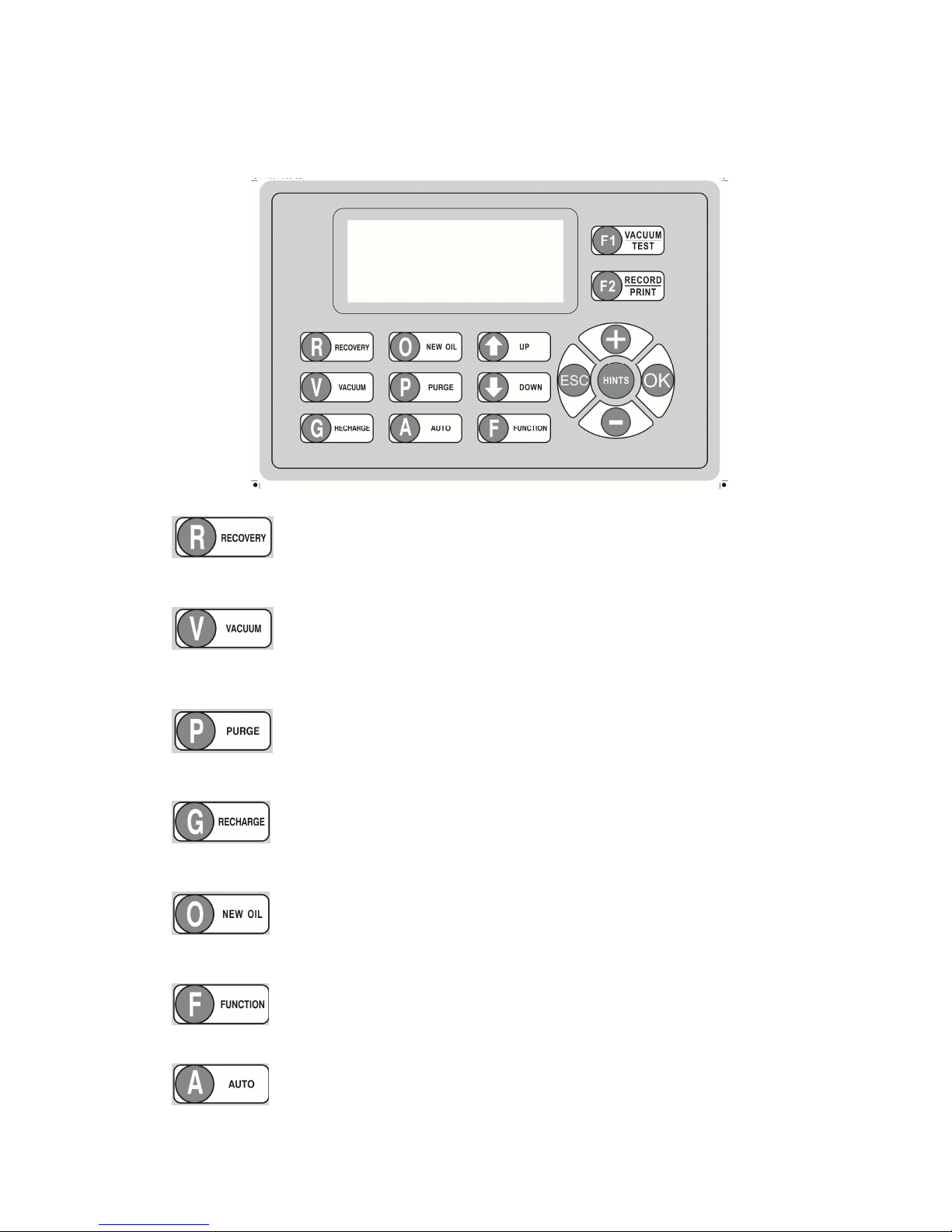

7 peration .........................................................15

7.1 Reco ery

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

7.2 Vacuum

. . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.3 Purge

. . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.4 Oil injection

.......................................................18

7.5 Recharge

..........................................................19

7.6 Auto

...........................................................20

7.7 Pressure up

.......................................................21

7.8 Pressure down

.....................................................21

7.9 Vacuum test

.....................................................22

7.10 Record print

. . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

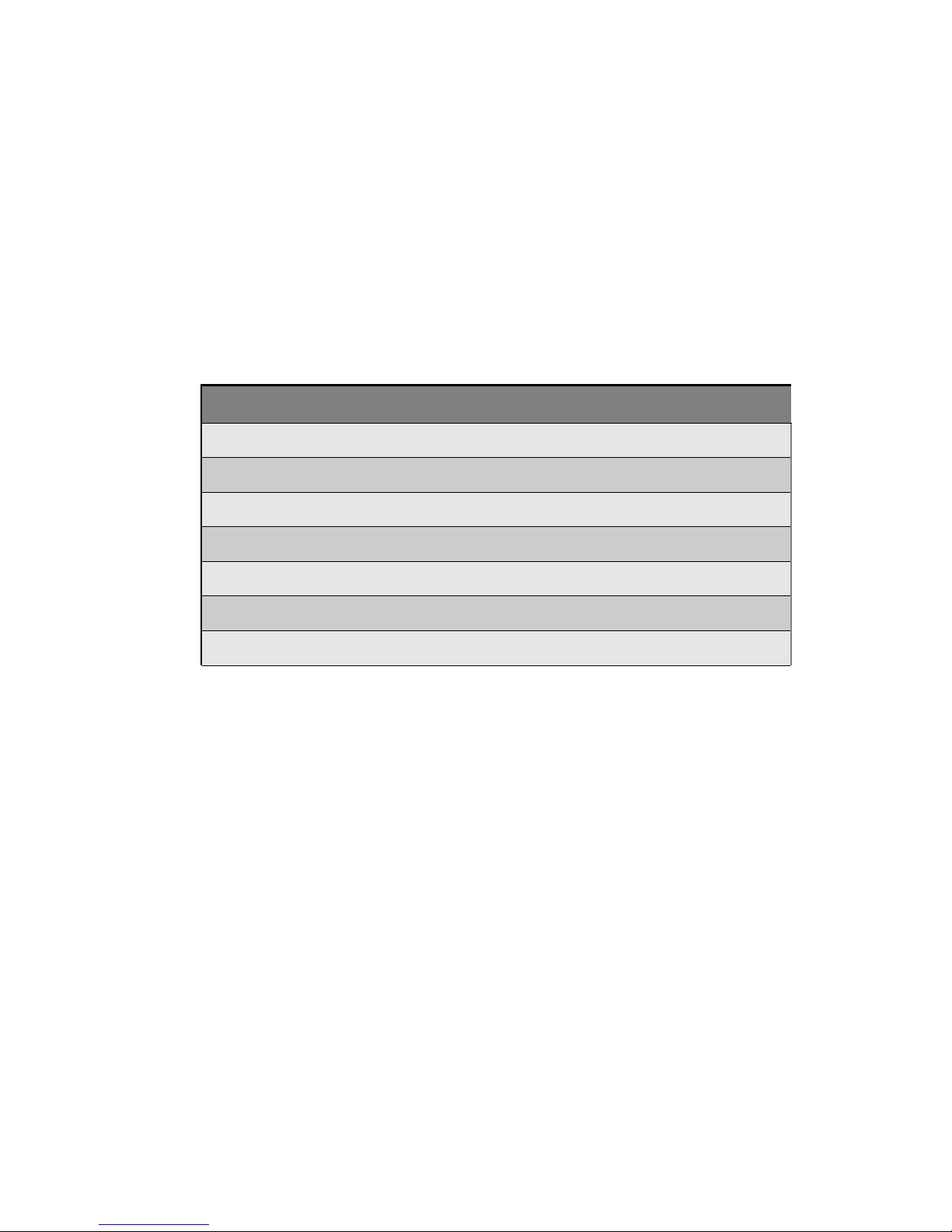

8. Service tasks .......................................................25

8.1 Inner tank refill . .................

.........

...........................

. . . .

25

8.2 Language select

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

8.3 Zero balance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . .25

8.4 acuum pump oil

. . . . . . . . . . . ( . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

8.5 Changing the internal filter

............................................27

8.6 Hose compensation

.................................................29

8.7 Pressure rise wait

...................................................29

8.8 Other ser ice

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.9 Cleaning and maintenance .............................................

. .

29

9. Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .30

9.1 Disposing of used fluids

..............................................30

9.2 Disposing of packaging material

.......................................30

9.3 Scrapping old unit

..................................................30

10 Trouble shooting...................................................31

11 Technical data ......................................................32

12 Spare Part list .....................................................32