TD 92022GB

2002-11-13/ Rev. A

Installation Guide

H/U952T Terminal Transmitter

8

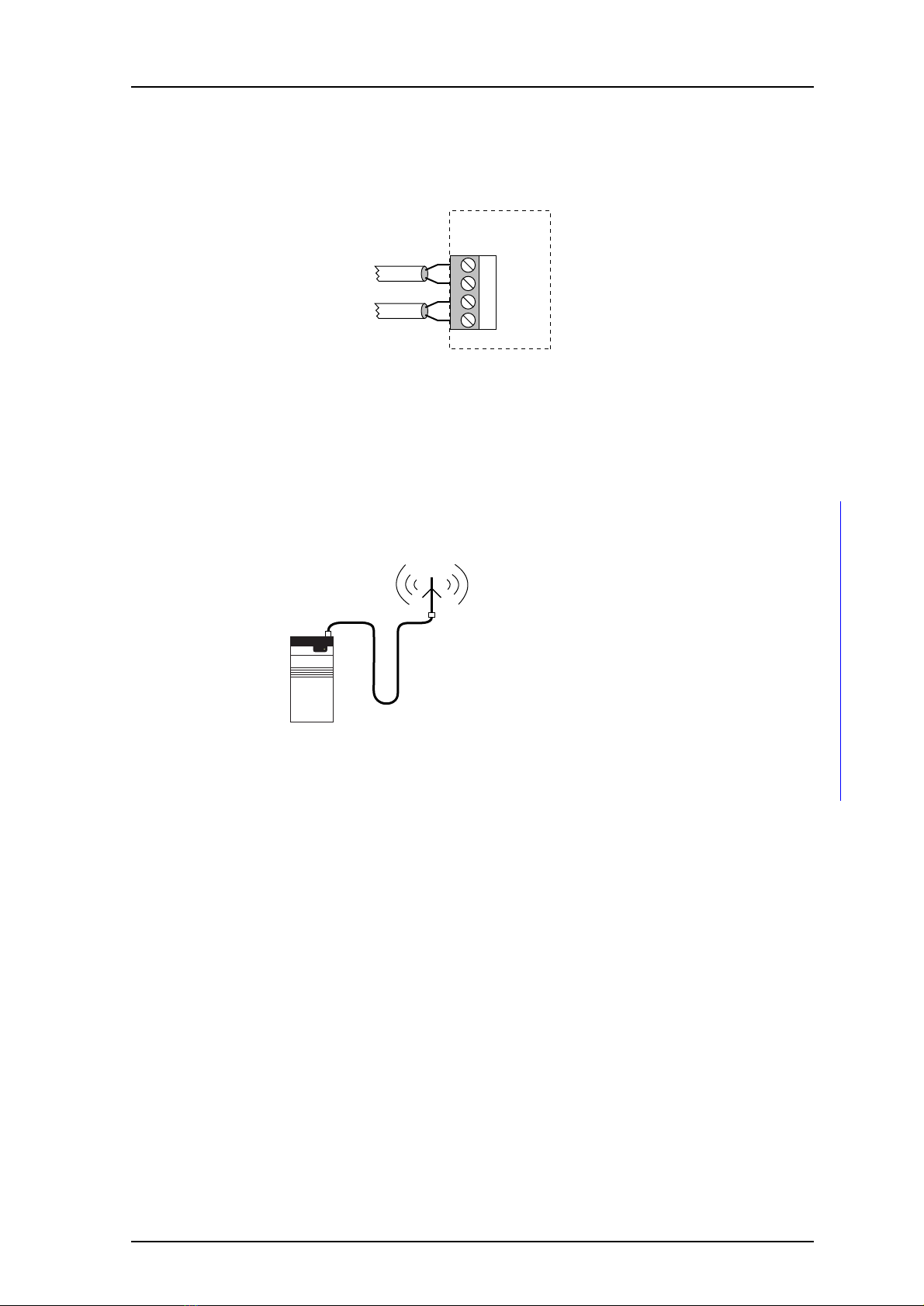

For installation of U952DR Slave Driver, see Installation Guide for U952DR, TD 92038GB.

The installation of MPT-50 is described in the Installation Guide for H950S,TD 90318GB.

Figure 12. Connection to Slave Transmitter in an UHF-system.

4 Parameter Settings

All parameters must be set in the U/H952 Flash PROM IC 101, before the tuning

procedure. The instruction for programming fixed equipment is described in

General Description PCPAR, TD 90799GB. Note that licence is required when FOM/SFO or

FL is used.

1 Open PCPAR and select software S952T.

2 Set the transmitter frequency in Hz.

3 Set the channel spacing.

4 If there is speech in the system check:

• Subtone frequency (default 127.3 Hz).

When FL (frequency locking) is used check:

• That frequency locking is enabled with the right reference frequency.

5 When FOM or SFO is used this has to be enabled with the right offset.

6 If the transmitter is to be used with old central software that do not support

U/H952T (specified in the parameter list), set the transmitter to act as an

U/H950T.

7 If FOM/SFO or FL is used, enter the required licence code.

8 When you have edited the parameter list, download the changes to flash prom

IC 101 and exit PCPAR.

5 Installation Test Procedure

1 Check that all sections of switch SW200 on the transmitter are set to OFF.

2 Check that address switch SW100 has the right address, see the System Installation

document, under Addressing.

Transmitter

Slave Driver Slave Transmitter