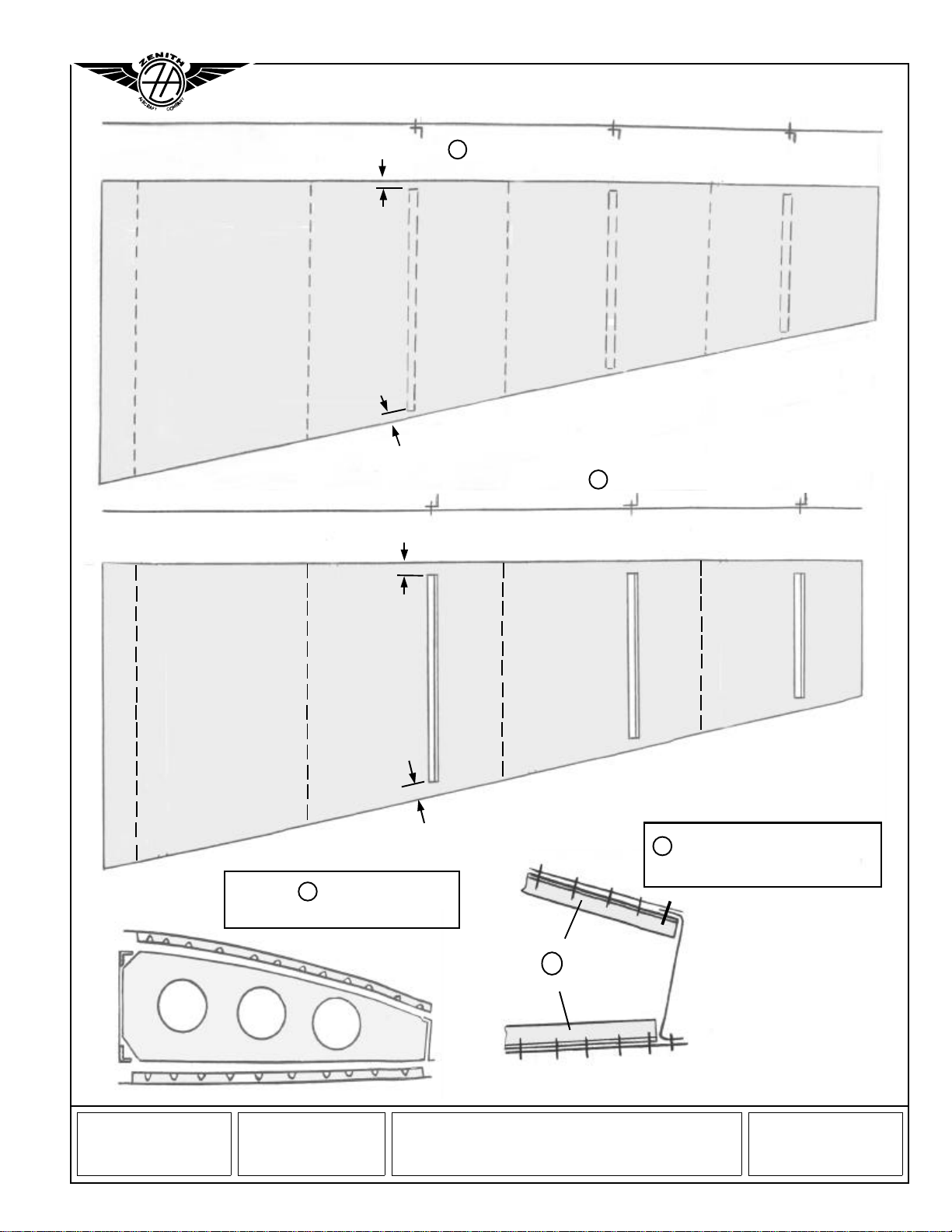

SPLICE PLATE & REAR ZEE LAYOUT V-4

Rib station #6 is layout on the Rear Zee by the positioning the Splice plate: first mark the postion

of the Rib at 24mm from the end of the Splice Plate, then position the Splice plate on the Rear Zee

on a 123mm overlap. The remaining Rib are evenly spacing at 571mm from Rib #6.

2. Cleco the Rear O/B Splice Plate 6SV4-2 to the Rear Zee 6V7-11

NOTE : Install the Splice Plate with the 20degrees up and the 33degrees down (reference 6V7

– for maximum clearance on the bottom for the Aileron control rod).

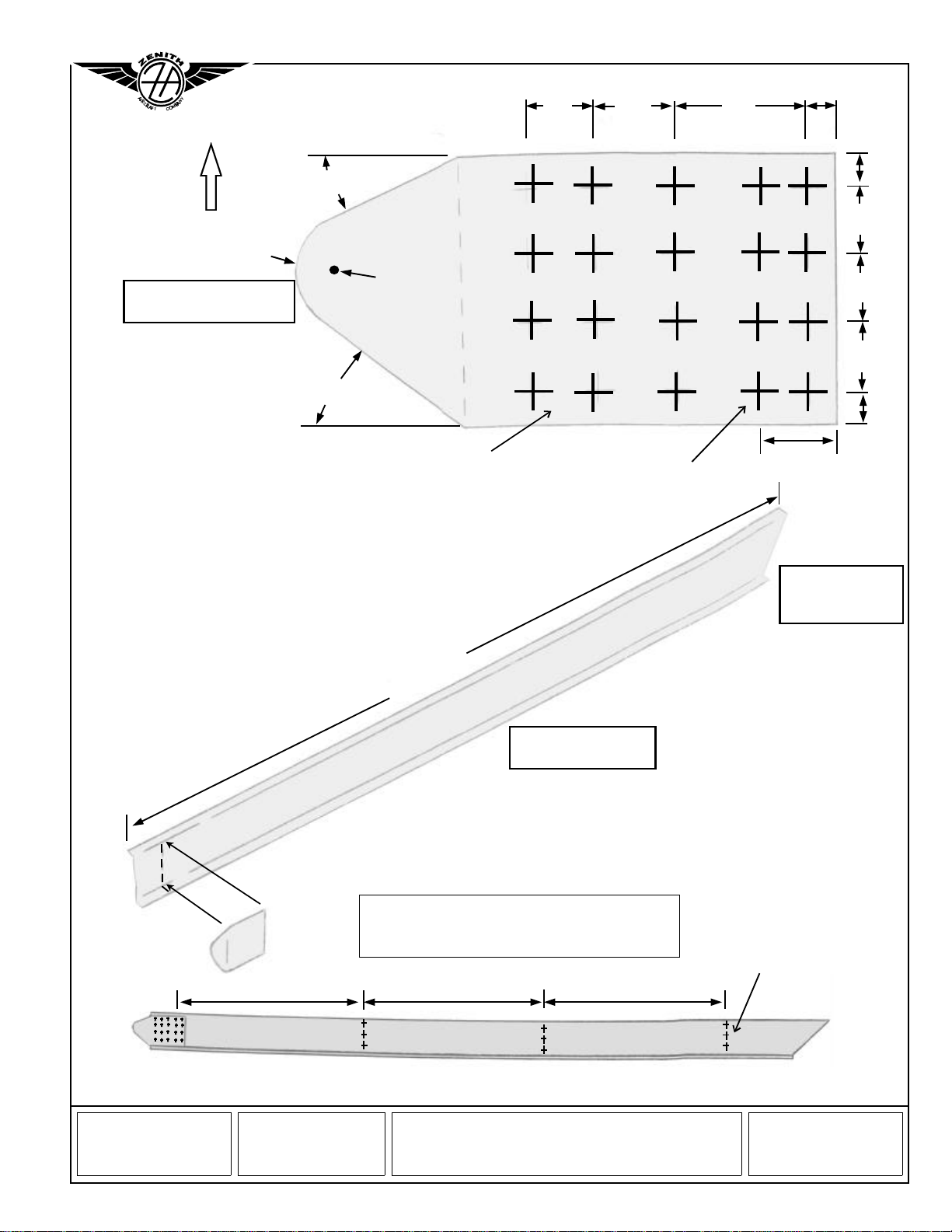

LAYOUT: a) On the Splice Plate 6SV4-2, mark the position of Rear Rib #6 at 24mm from the

O/B end of the Plate. Rib #6 is designated as “o” on drawing 6SV4 with 5 A5

b) Mark the 4 rivet lines.

NOTE : On the Main Spar, Rib #6 is set at 110mm measured along the top spar extrusion, see

bottom right diagram on 6SV1 and top left diagram on 6SV2

PRE-DRILL: With undersize pilot holes #40

CLAMP: The Splice Plate to the Rear Zee, the parts overlap 123mm (2380 - 2257 = 123).

CHECK: a) That the bottom of the Splice Plate is positioned at the beginning of the bent

tangent line of the bottom Rear Zee flange.

b) The top of the Splice Plate is slightly lower than the top flange of the Rear Zee.

b) The end of the Rear Zee is on or just shy of the 15 degree bend tangent line of

the Splice Plate (6SV4-2 is bent 15 degrees towards the front).

c) 100mm from the inboard (I/B) end of the Rear Zee to the center line of Rib #6

DRILL & CLECO:

a) Back-drill the Rear Zee at Rib #6 with pilot holes #40

b) Back-drill the 4 rivet lines with #20

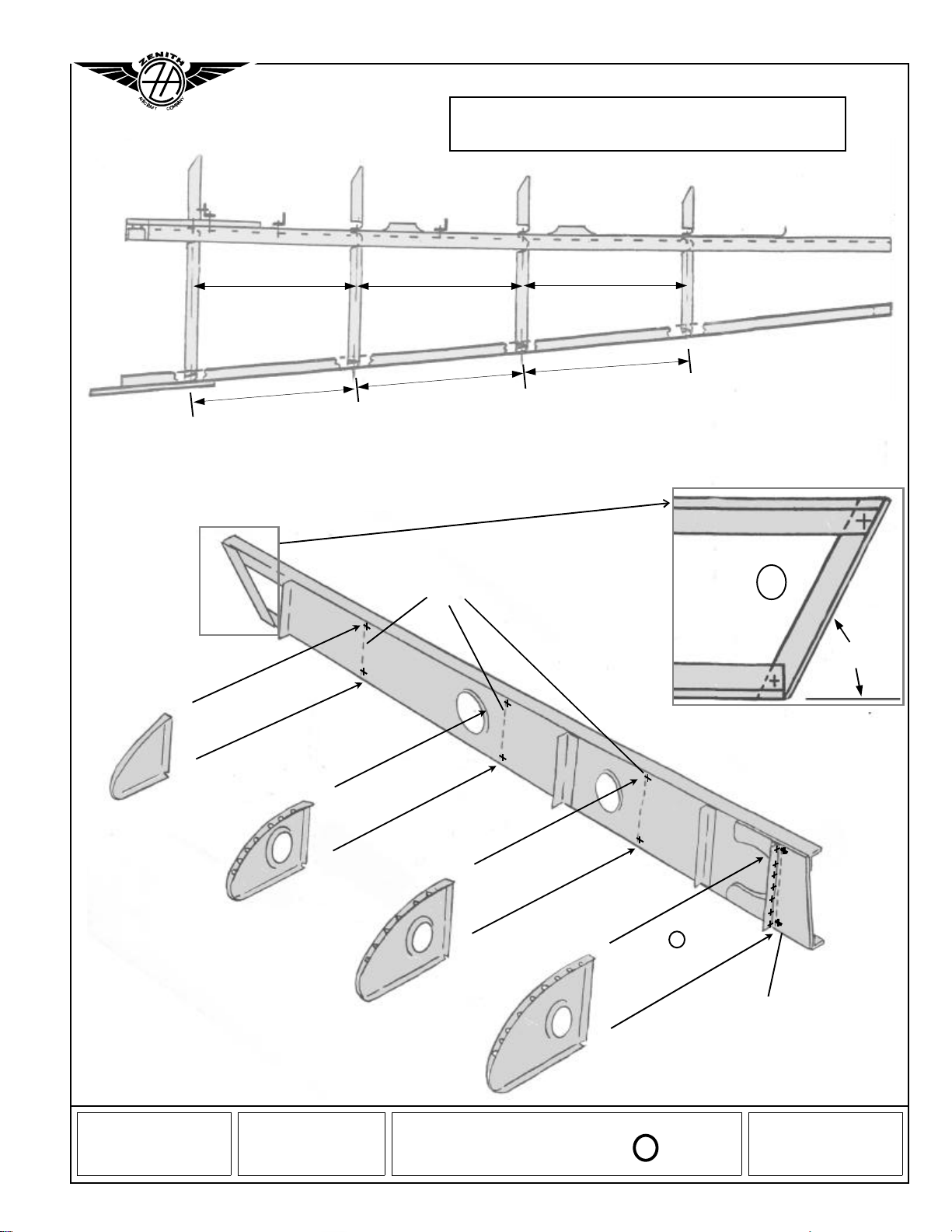

3. Pre-drill the Rear Zee 6SV4-2 for the Rear Ribs.

LAYOUT: The Ribs are at 90 degrees to the bottom flange of the Rear Zee. The Ribs are evenly

space 571mm apart starting at Rib #6

CHECK: Hold the Rear Zee along the aft trailing edge of the Skins and check for the Rib

alignments with the pre-drilled skins.

SUGGESTION: To determine the position of the end holes (top and bottom hole on the Rear

Zee), clamp a Rear Rib to the top flange of Rear Zee to mark the top and bottom end hole for

good edge distances of approximately 10mm. (Referenced from the bottom flange, the three

holes are at: 12, 40 and 70mm).

PRE-DRILL: The rib stations with pilot hole #40 in the Rear Zee. The 11 degree flange faces

forwards towards the main spar.

4. Cut the O/B end of the Rear Zee 6V7-11 at 45 degrees.

REFERENCE: Rear Zee drawing on the upper left diagram on drawing 6SV4

LAYOUT: The overall length measured along the top flange is 2380mm.

CHECK: The distance measured along the top flange from the O/B tip to Rear Rib #9 is

567mm.