or anything that could affect your vision, alertness,

coordination or judgement.

• Do not use the product in bad weather such as

dense fog, heavy rain, strong wind, intense cold,

etcetera. Working in bad weather is tiring and often

brings added risks, such as icy ground,

unpredictable felling direction, etcetera.

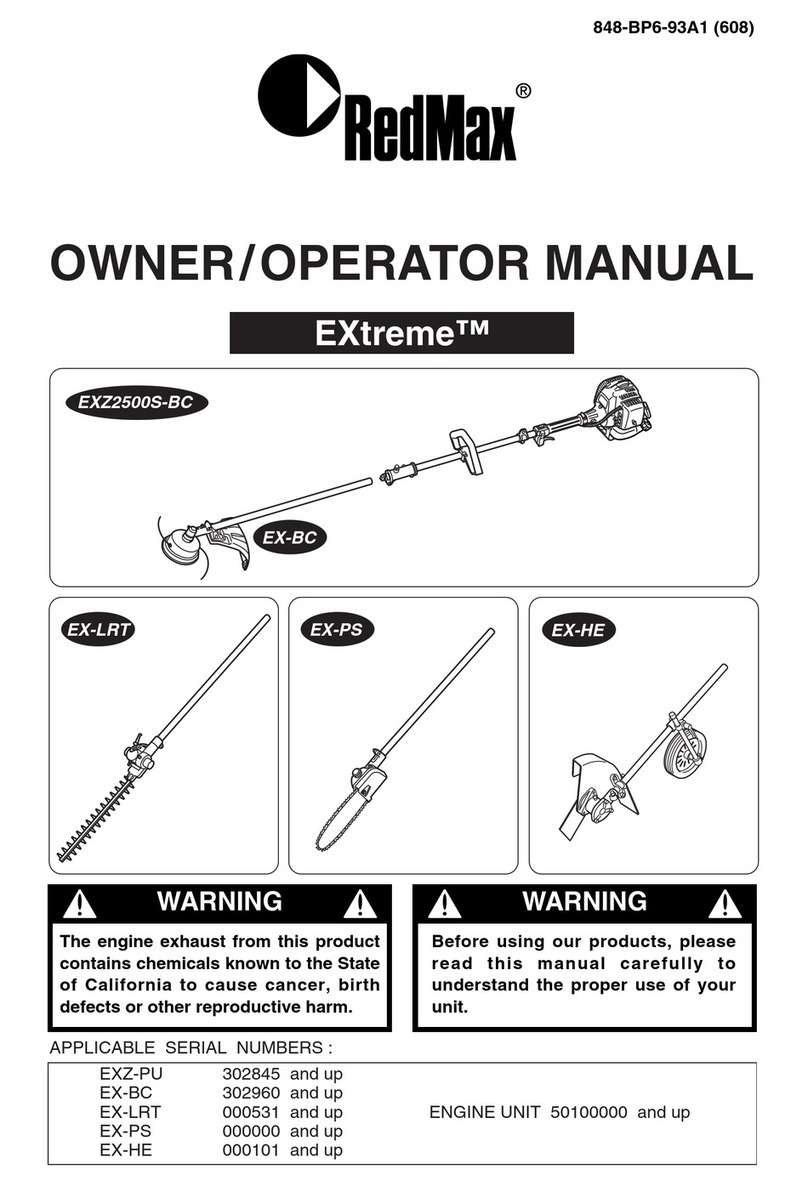

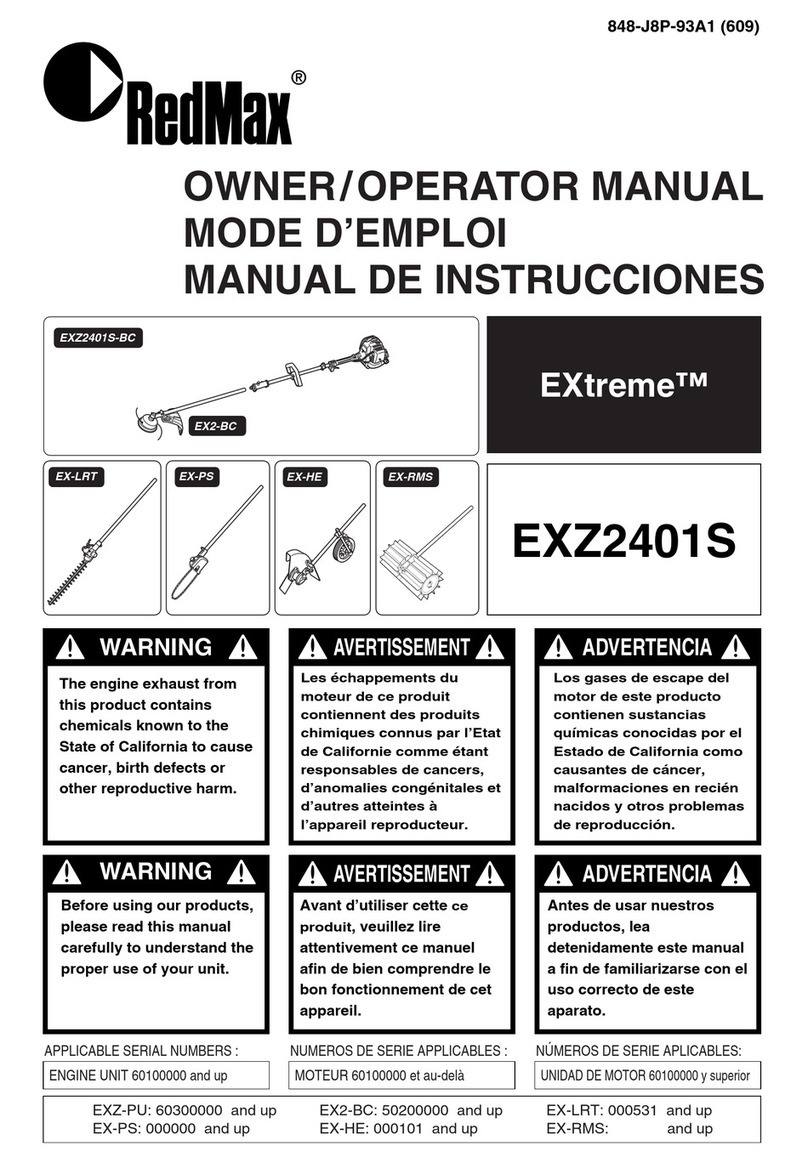

• The only accessories you can operate with this

engine unit are the cutting attachments that we

recommend in the chapter

#

.

• Never allow children to use or be in the vicinity of the

product. As the product is equipped with a spring-

loaded start/stop switch and can be started by low

speed and force on the starter handle, even small

children under some circumstances can produce the

force necessary to start the product. This can mean

a risk of serious personal injury. Therefore remove

the spark plug cap when the product is not under

close supervision.

• Running an engine in a confined or badly ventilated

area can result in death due to asphyxiation or

carbon monoxide poisoning.

• The complete clutch cover and shaft must be fitted

before the product is started, otherwise the clutch

can come loose and cause personal injury.

• Ensure that no people or animals come closer than

15 metres while you work. When several operators

are working in the same area the safety distance

should be at least 15 metres. Otherwise there is a

risk of serious personal injury. Stop the product

immediately if anyone approaches. Never swing the

product around without first checking behind you to

make sure that noone is within the safety zone.

• Ensure that people, animals or other things can not

affect your control of the product or that they do not

come in contact with the cutting attachment or loose

objects that are thrown out by the cutting

attachment. However, do not the product unless you

are able to call for help in the event of an accident.

• Always inspect the working area. Remove all loose

objects such as stones, broken glass, nails, steel

wire, string, etcetera, that could be thrown out or

become wrapped around the cutting attachment.

• Make sure that you can move and stand safely.

Check the area around you for possible obstacles

(roots, rocks, branches, ditches, etcetera) in case

you have to move suddenly. Take great care when

you work on sloping ground.

• Keep a good balance and a firm foothold at all times.

Do not overreach.

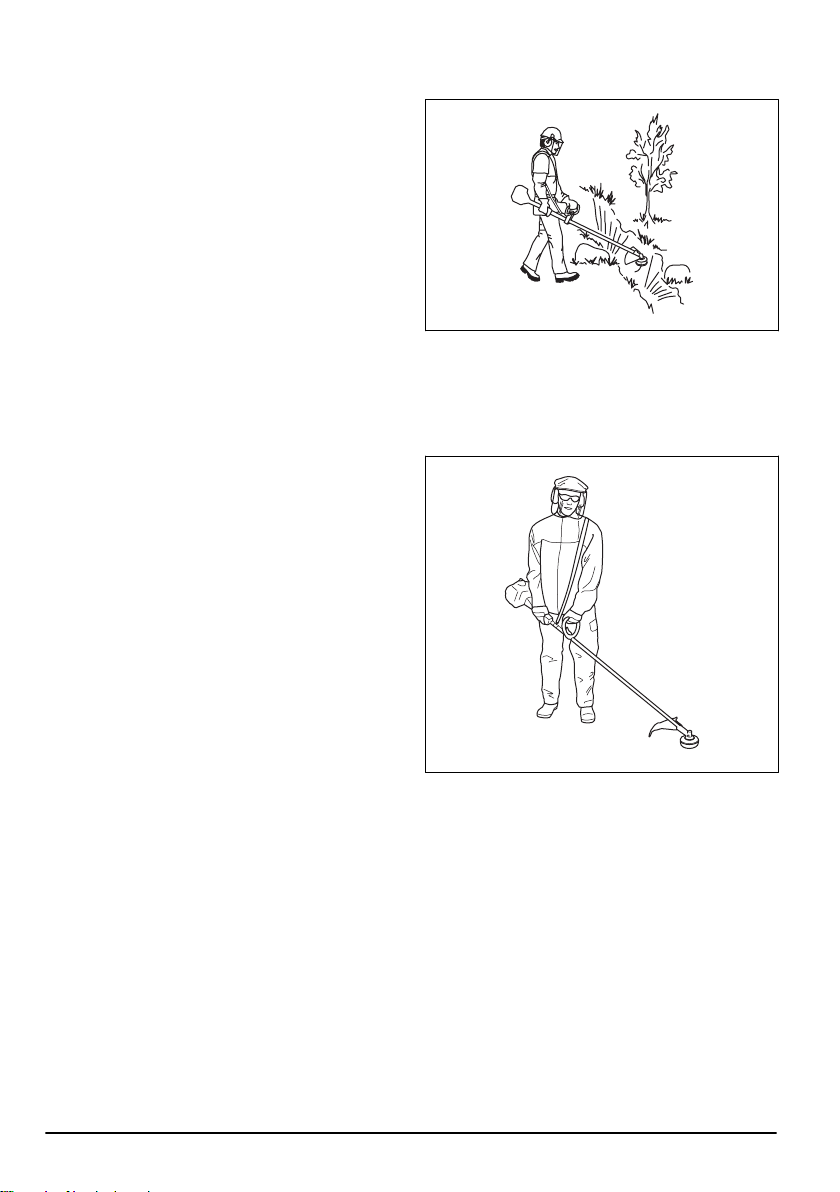

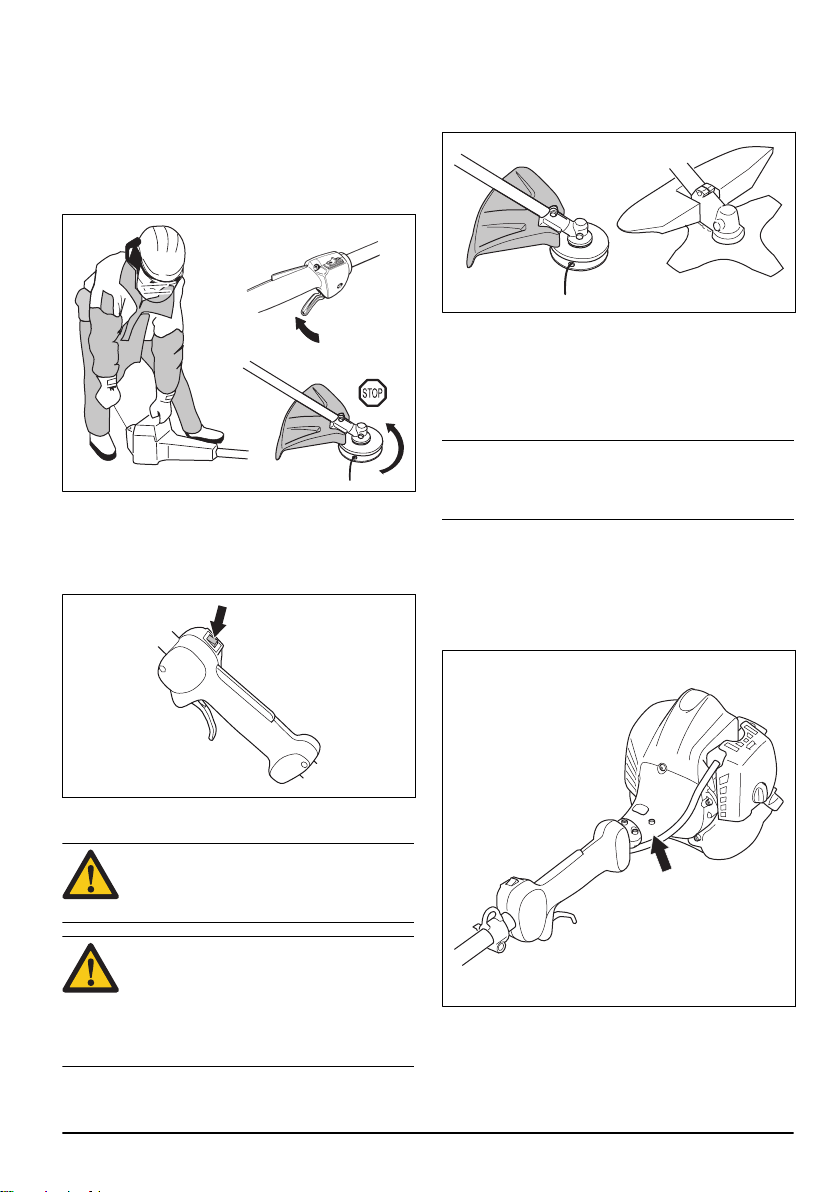

• Always hold the product with both hands. Hold the

product on the right side of your body.

• Make sure that you attach the harness to the

suspension ring.

• Keep the cutting attachment below waist level.

• Switch off the engine before you move to another

area. Fit the transportation guard before you carry or

transport the equipment any distance.

• Never put the product down with the engine running

unless you have it in clear sight.

• Stop the engine and cutting equipment before you

remove material that has wound around the blade

shaft. Neither the operator of the product nor anyone

else may attempt to remove the cut material while

the engine is running or the cutting equipment is

rotating, as this can result in serious injury. The

bevel gear can get hot during use and may remain

so for a while afterwards. You could get burnt if you

touch it.

• Watch out for thrown objects. Always wear approved

eye protection. Never lean over the cutting

attachment guard. Stones, rubbish, etcetera, can be

6353 - 003 - 06.01.2018