II

Table of Contents

INTRODUCTION.....................................................................................................1

PLANNING..............................................................................................................3

DELIVERY...............................................................................................................4

Moving Display Case........................................................................................4

SETTING THE CASE..............................................................................................5

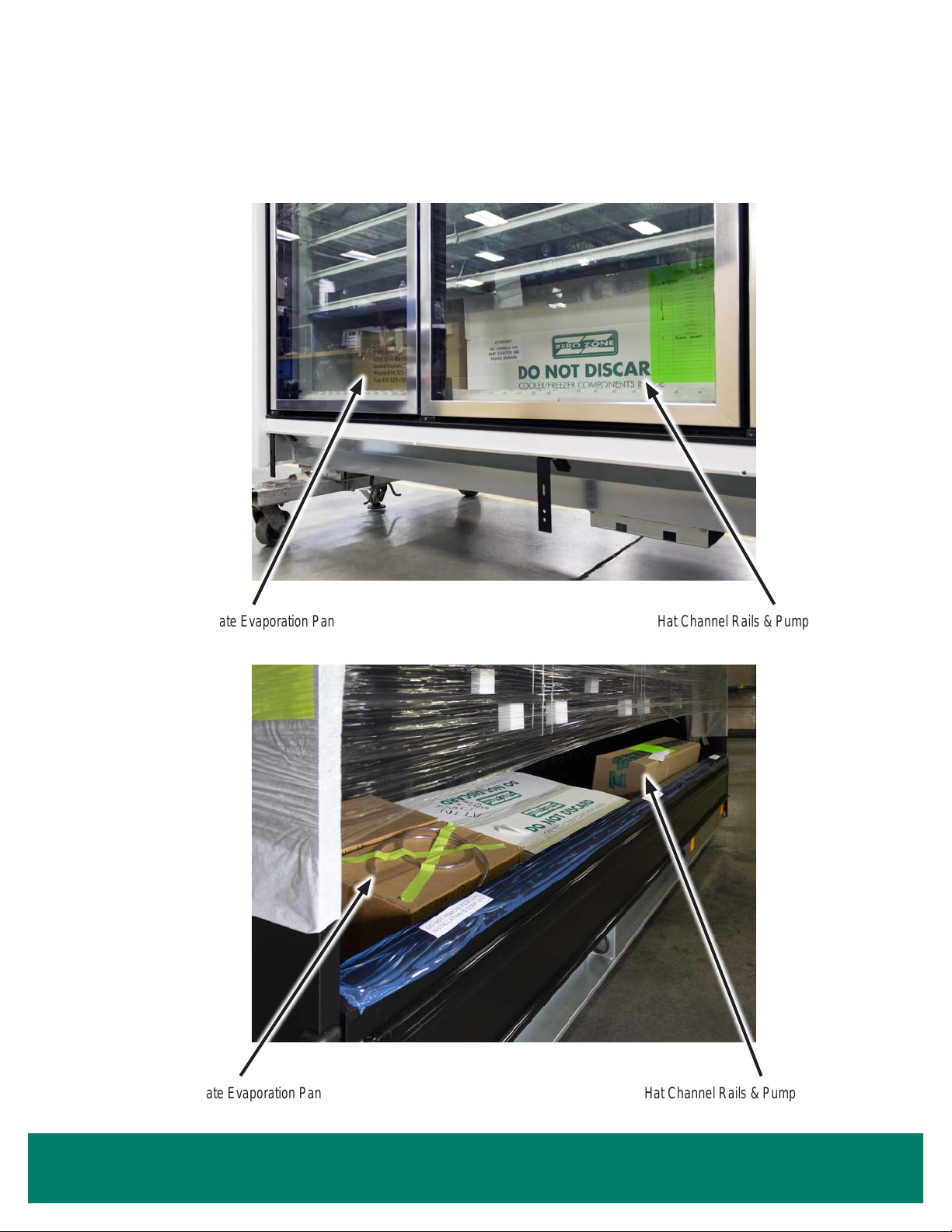

Contents Shipped Inside of Case.....................................................................5

Positioning Hat Channel Rails..........................................................................6

Dividers Between Cases...................................................................................7

Reveal Merchandiser® Support Brace - Removal & Installation......................8

Reveal Merchandiser® Support Brace - Position Components......................11

CONDENSING UNIT CONNECTION....................................................................12

Setting the Condensing Unit...........................................................................12

Quick-Connect Couplings...............................................................................13

Insulation on Suction Line Quick-Connect......................................................14

ELECTRICAL/CONTROL.....................................................................................15

Case Electrical Connections - Highlight Merchandiser®................................15

Case Electrical Connections - Crystal Merchandiser®...................................16

Case Electrical Connections - Reveal Merchandiser®...................................17

Case Electrical Connections - Pinout Locations.............................................18

Condensing Unit Electrical Connections.........................................................19

PLUMBING...........................................................................................................20

Pump with Bracket Installation Instructions....................................................20

Dual Evaporation Pan Set Up.........................................................................24

Power the Condensate Evaporation Pan........................................................25

Case Drain Line to Floor Drain ......................................................................26

Booster Pump Installation...............................................................................27

CASE TRIM...........................................................................................................28

Bumper & Kickplate........................................................................................28

OPERATION .........................................................................................................29

Controller Sensor Wires..................................................................................29

Start-Up...........................................................................................................30

Carel IR33+ Controller Standard Features.....................................................30

Instructions for Setting the Time - Carel IR33+ Controller..............................30

Turning the Lights On & Off............................................................................31

Solid Shelf Installation & Removal..................................................................32

Wire Shelf Installation & Removal...................................................................33

Door Hold-Open Bracket.................................................................................34

Electrical Enclosure Wire Colors.....................................................................35

When installing a Hybrid Merchandiser™, refer to both this manual and the associated

remote installation & operation manual.