INDEX

5

EN 3201.758.001a 2016-02

INDEX

1. INTRODUCTION ...............................................................................................................7

1.1. INTRODUCTION ....................................................................................................................................7

1.2. CONVENTIONS FOR SAFETY INFORMATION IN TEXT ...........................................................................8

1.3. GENERAL INFORMATION ......................................................................................................................9

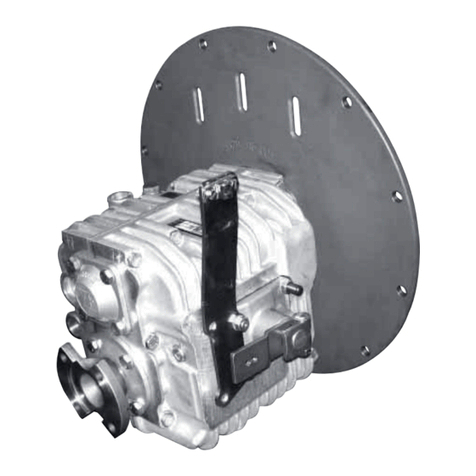

2. INSTALLATION AND OPTIONS .........................................................................................13

2.1. STANDARD INSTALLATION AND ASSEMBLY ........................................................................................13

2.2. PROPELLER SHAFT CONNECTION ........................................................................................................13

2.3. CONTROL VALVE SHIFT CONTROL LINKAGE .........................................................................................14

2.4. TOWING ................................................................................................................................................15

2.5. GEARBOX FASTENING ..........................................................................................................................16

3. TECHNICAL DATA ............................................................................................................17

3.1. TECHNICAL DATA .................................................................................................................................17

3.2. OIL TYPE ...............................................................................................................................................17

4. MAINTENANCE ................................................................................................................18

4.1. MAINTENANCE SCHEDULE ..................................................................................................................18

4.2. OIL LEVEL CHECK ..................................................................................................................................19

4.3. ADJUSTING SHIFT CONTROL LINKAGE .................................................................................................21

4.4. CHECKING FLEXIBLE COUPLINGS .........................................................................................................21

5. WARRANTY ......................................................................................................................22

6. TROUBLESHOOTING ........................................................................................................23