MAN 06-0015: Chapter Rev. A Page 1

Table of Contents

Audience.............................................................................................. 1

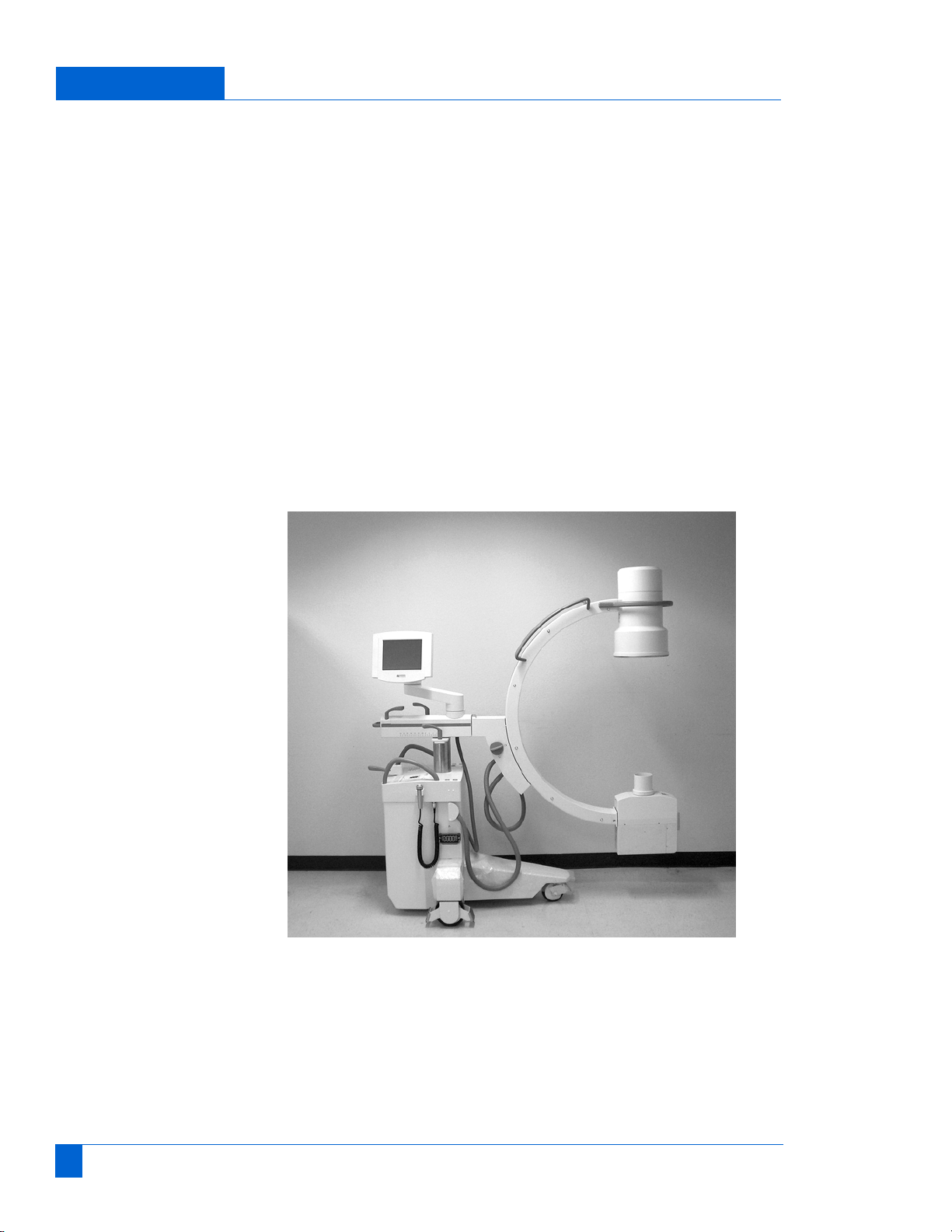

Unpacking the

C-Arm .................................................................................................. 1

Mounting Monitors............................................................................... 2

AC Power Check ................................................................................. 4

Mechanical Movement......................................................................... 5

CDRH Report ...................................................................................... 5

Maintenance Report

Introduction.......................................................................................... 1

Safety .................................................................................................. 2

Documentation .................................................................................... 2

Image intensifier .................................................................................. 2

Labels.................................................................................................. 3

Switch Safety Cutoff .......................................................................... 12

Radiation Indicators........................................................................... 12

Fluoroscopy Time (see 21 CFR 1020.31 (a)).................................... 12

Check kV Values ............................................................................... 12

Check Tube Current .......................................................................... 14

Check Radiographic Tube Current.................................................... 14

Check Reproducibility........................................................................ 15

Beam Quality..................................................................................... 18

Exposure Times................................................................................. 21

Maximum Dose Rate......................................................................... 22

Checking Central X-Ray Beam.......................................................... 23

Adjusting Central X-Ray .................................................................... 25

Tube Head Adjustment...................................................................... 26

Check Collimation.............................................................................. 30

Image Intensifier Format.................................................................... 32

Cassette Format................................................................................ 32

Smallest Field Size............................................................................ 34

Mechanical ........................................................................................ 36

........................................................................................................... 39

Technical data ................................................................................... 39

........................................................................................................... 42

Cleaning, Disinfecting, and Sterilization ............................................ 42