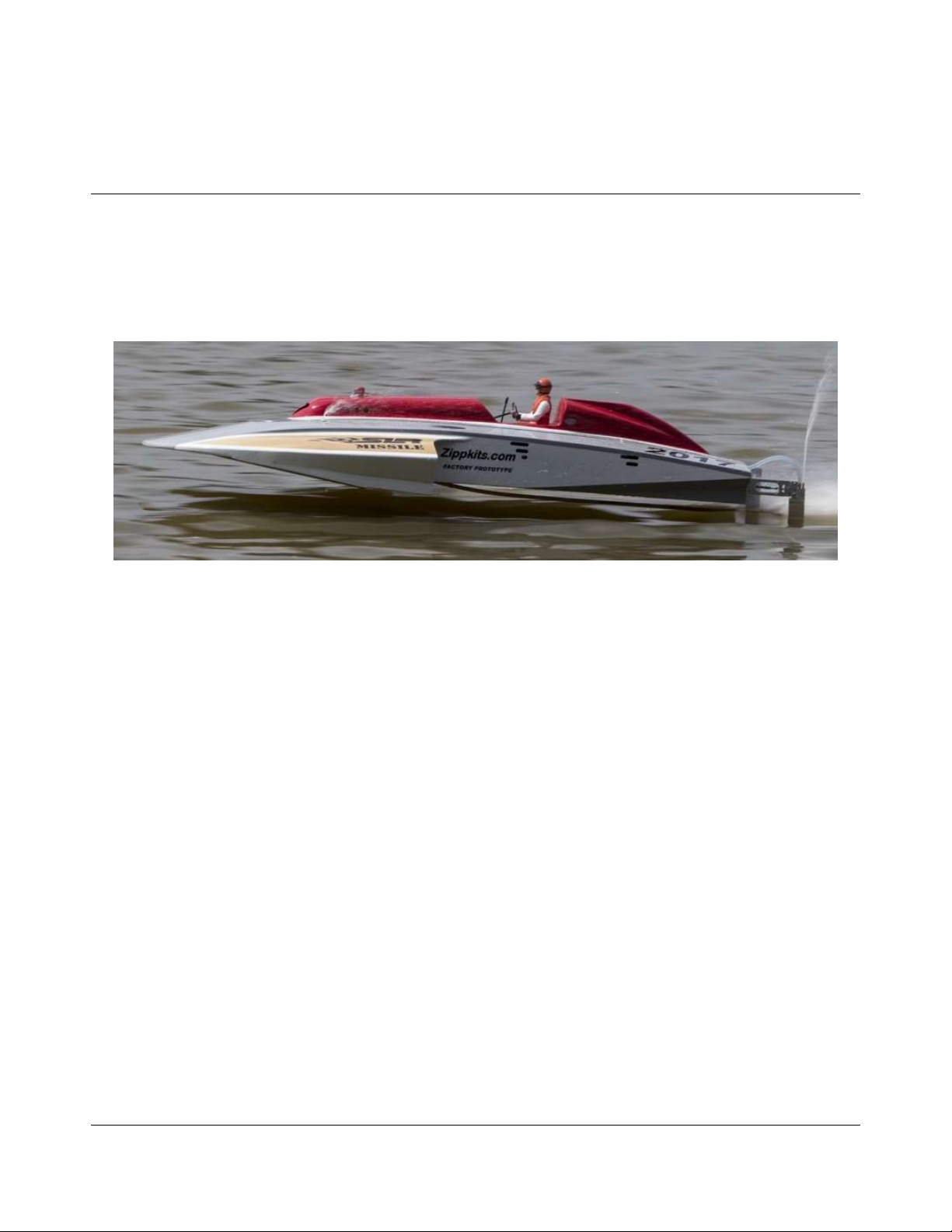

S L R M I S S I L E

This record holding design was developed by Scott Liddycoat, full size boat racer

(holder of several US 1 championships) and monster truck driver.

Hence the SLR designation for Scott Liddycoat Racing.

Thunderboats are scale type hydros specifically designed for gasoline power.

The Missile was designed as an easy to build kit that is also easy to setup, and

very predictable to drive. It has excellent stability and turning ability, and handles

rough water very well.

The secret to its outstanding performance is the modern design features, such as

the sponson angle of attack, non-trip and deck crown. All these elements add up to

an aerodynamically sound design.

The SLR Missile adds several new design elements that make the boat more

efficient (faster) and easier to build.

The SLR Missile is also legal in all Thunderboat classes in both IMPBA and

NAMBA.

You can build this boat without having the engine or radio, but it does make it

easier to have them available when you build.

You can use any gasoline engine, as long as it has mounts for 5 inch rails.

Please note that this boat was designed for the Zenoah style marine engines.

Other engines may not fit without cutting, and may not fit under the cowling.

The SLR Missile was designed and optimized through 4 different hulls.

This allows us to make small changes, and provides you with the very best we

have to offer for performance and ease of assembly.

Because of this, the pictures may differ slightly from your parts, or a picture may

seem out of sequence. This is normal, and is due mostly to running changes in the

design.