8

In the LAN, this machine should be assigned an IP address and related information. Click

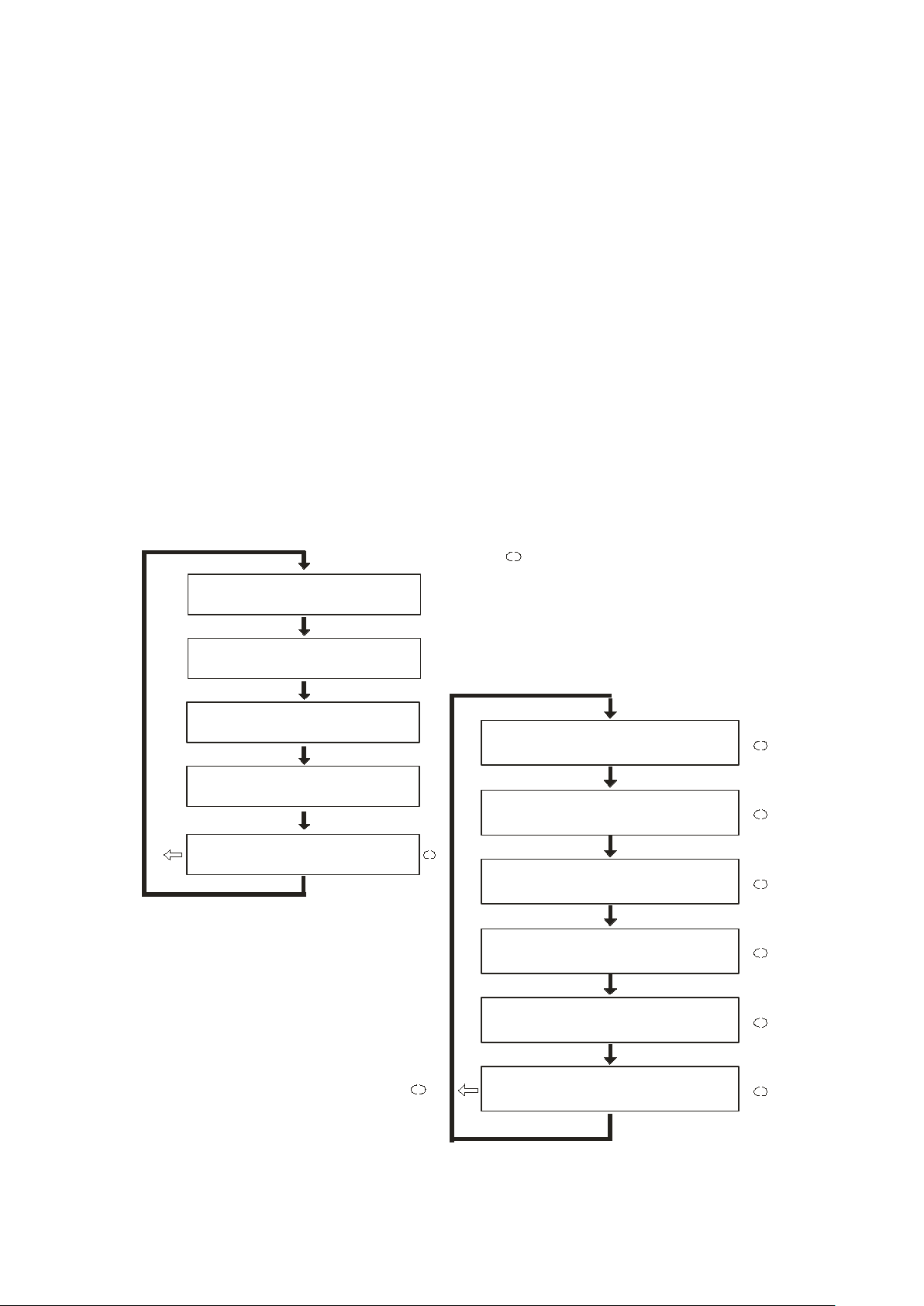

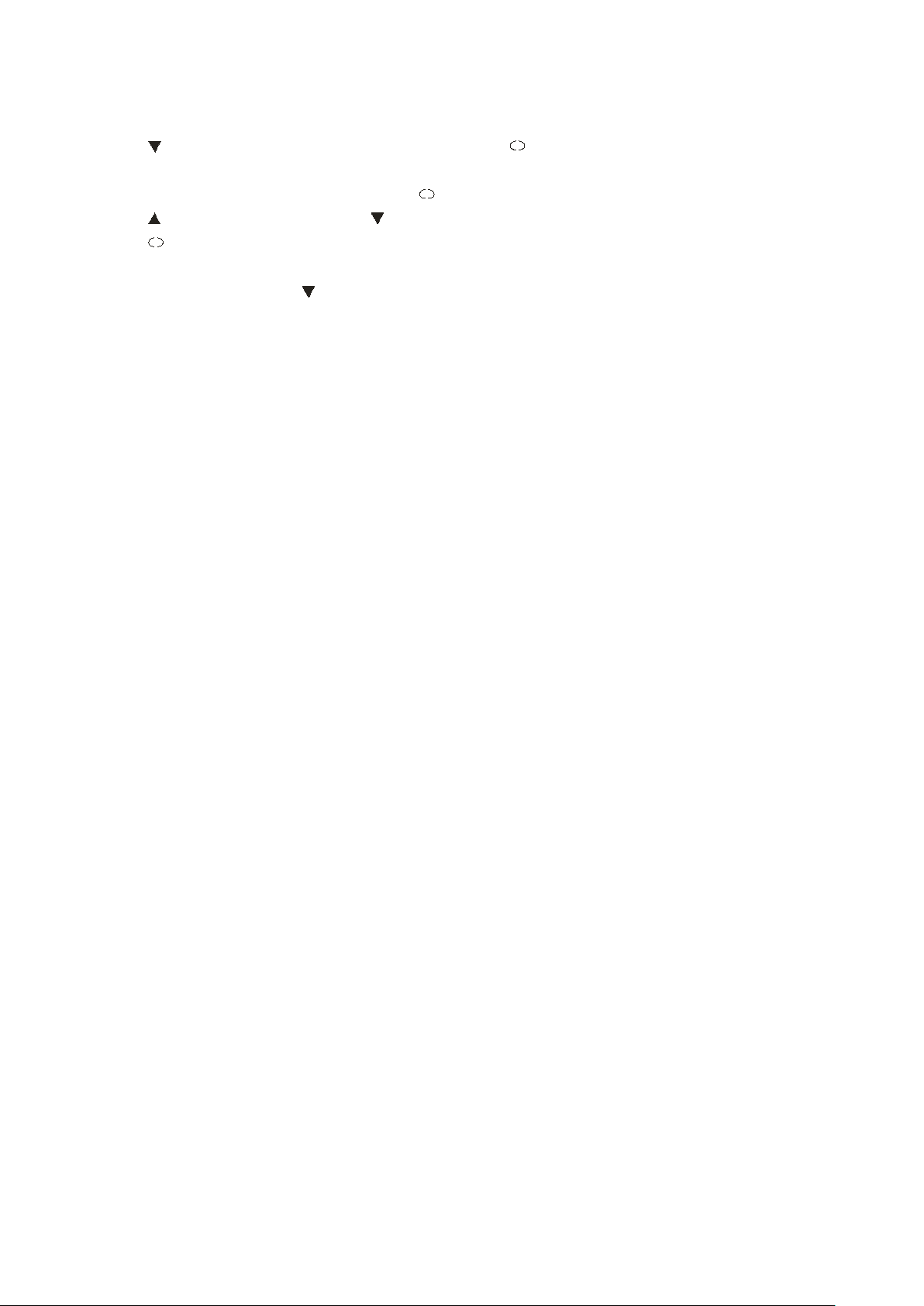

" " to enter "NETWORK CONFING. A" and click " " to enter in Figure (4) The Flowchart

shown in page 3.1.

4.3.1) Setting IP address: Press key " " to enter the first in paragraph 1 of IP address, click

" " the number increases, click " " number decreases, after the number is selected well ,press

" " key to enter the second setting, and so on. If there is only one paragraph, the front figures are

0.

4.3.2) mask: Click " " to enter the following sequence flow chart on page A.2, general

equipment has been set "255.255.255.000" in the factory, so adjustment is unnecessary.

4.3.3) Default Gateway: Setting method ibid.

4.3.4) the preferred DNS settings: Setting method ibid.

4.3.5) alternate DNS settings: Setting method ibid.

5 Network management applications

HFC network management system, has always been a difficulty that concerned by users and

manufacturers. Imported equipment is generally claimed with a network management system

which is based on industry standard RS232 or RJ45 interface. In order to achieve the network

management, the users need to purchase high-cost private network management software. And

each manufacturer's software is not compatible with each other. To achieve network management

is very difficult. At present there are no news reports about available network management in

Domestic system. If adopt the SNMP, the users also need to purchase specialized network

management software and there are incompatible issues between manufacturers. Many domestic

manufacturers also claim that their equipments have a network management system or are

compatible with the AM company network management system. but the device's RJ45 or RS232

interface is basically vacant and cannot achieve the network management functions.

Our company is the well-known manufacturers in the cable broadband optical transmission

system. We have been concerned about how to use the most economical and most convenient way

to achieve the network management in the cable broadband networks. Now the ESV6.0 network

management system launched by our company is a new network management concepts based on

the SNMP / TCP / IP protocol.

5.1) Interface of integrated work of the monitor server

After plugging the optional transponder, the machine has the function of network management,

just need to connect the RJ45 interface signals to the LAN, and connect to the main server from

any of the LAN Ethernet port., then set up IP addresses, according to the method in 4.A etc. so we

can monitor the machine’s running conditions at real time when the network management system

is running.