ZKTeco OP1000 Series User manual

User Manual

OP1000 series

Applicable Models: OP1000/1200, 1011/1211, 1022/1222

Version: 1.0

Date: December 2018

Content

1. Product Introduction.........................................................................................................................................................1

1.1 Model number and access control...................................................................................................................1

1.2 Chassis design and dimensions.......................................................................................................................... 1

1.3 Function features.........................................................................................................................................................2

1.4 Electronic control system.......................................................................................................................................2

1.5 Specifications.................................................................................................................................................................3

2. Electrical test before installation............................................................................................................................... 4

3. Electrical and civil installation......................................................................................................................................4

3.1 Equipment installation condition and position........................................................................................4

3.2 Cables installation.......................................................................................................................................................5

3.3 Equipment installation and fixing..................................................................................................................... 6

3.4 Set up a warning line ................................................................................................................................................6

4. Equipment wiring and debugging.........................................................................................................................7

4.1 Internal wiring diagram...........................................................................................................................................7

4.2 Master and slave wiring diagram....................................................................................................................... 7

5. Menu Introduction............................................................................................................................................................8

5.1 Function introduction ..............................................................................................................................................8

5.2 Menu introduction ..................................................................................................................................................... 8

5.3 Operation and instruction of menu.............................................................................................................. 10

6. Product Maintenance .................................................................................................................................................... 12

6.1 Chassis maintenance.............................................................................................................................................. 12

6.2 Power maintenance................................................................................................................................................ 12

OP1000 series User Manual 1

1. Product Introduction

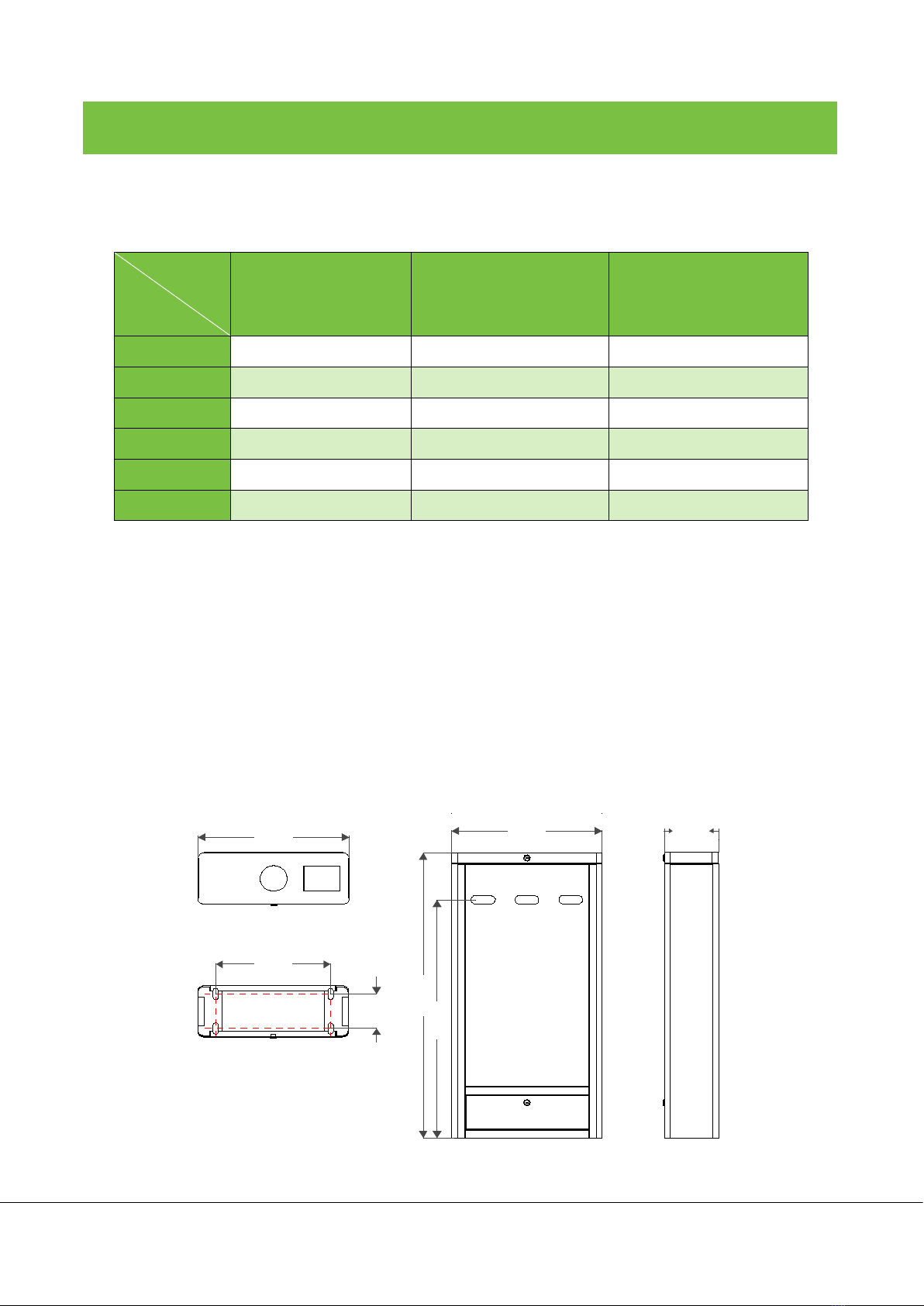

1.1 Model number and access control

Access

Model

None C3-200 and 2*KR800E

readers

inBio 260 and 2*

FR1500 readers

OP1000 √

OP1011 √

OP1022

√

OP1200 √

OP1211 √

OP1222 √

1.2 Chassis design and dimensions

OP1000 series is with SUS304 housing, anti-corrosion and durable. It serves as a carrier, equipped with

the direction indicator, reader, infrared sensor, door lock, and more. It provides legal access to persons

while eliminating illegal access by setting alarm prompts. In case of emergency, it ensures that

evacuation passage runs smoothly and is convenient for personnel.

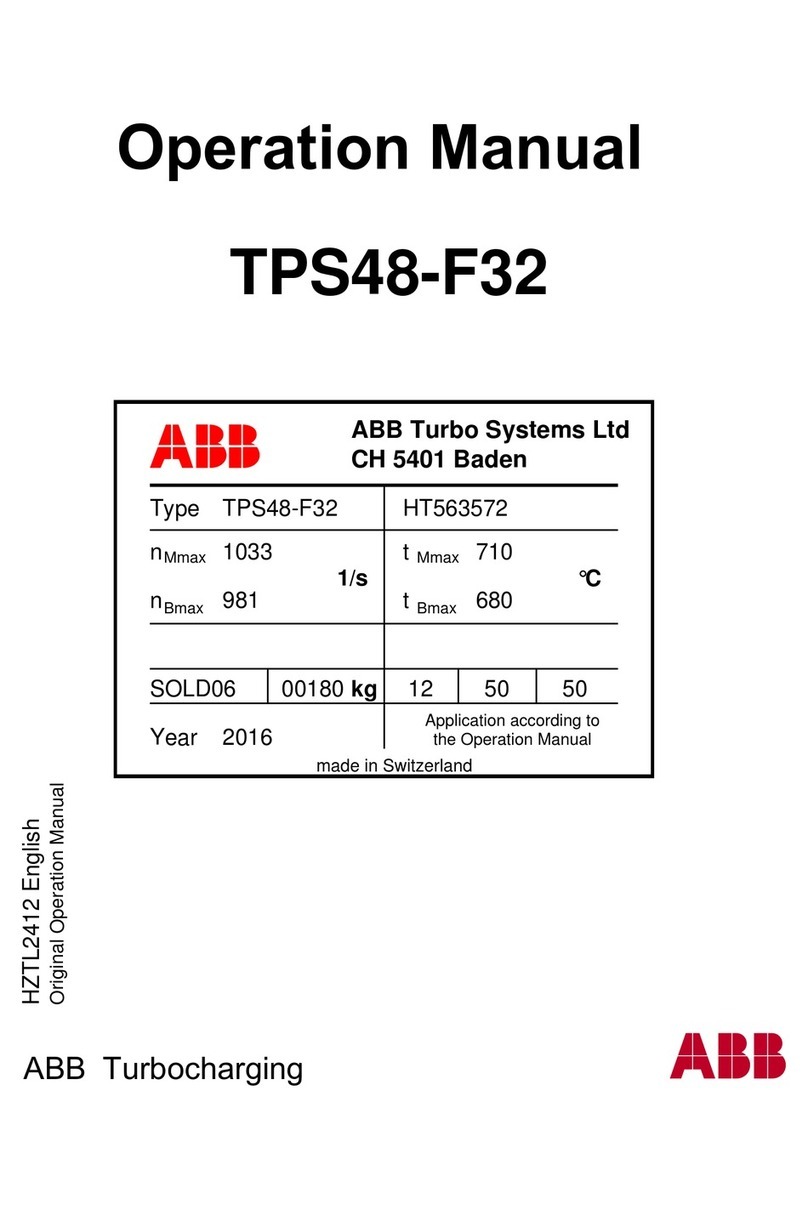

The appearance and dimensions of OP1000 are as shown in Figure 1-1:

Figure 1-1

120.00

380.00

500.00 180.00

1000.00

835.00

500.00

2OP1000 series User Manual

1.3 Function features

1. It offers clear direction indicating whether it is allowed to walk through the device with intuitive

LED light.

2. Anti-trailing function: the system will automatically trigger the alarm when it, for instance, detects

a person closely following the person in front with the intention to pass without card swiping.

The alarm will be raised until the pedestrian exits the passage; Rebrush valid CARDS to allow pass.

3. There are a variety of working modes available for two-way traffic. Infrared alarm or the main

board release signal (need for additional access control system, access control, fingerprint, etc.)

can be set on the main board menu.

4. It has the function of canceling the passageway permission: when a person does not pass

through the device within a specified time after receiving the release signal, the system will

automatically cancel the passageway permission. You may set the time duration on the main

board menu.

5. It has the function of fire control free passage. When there is a fire, the trigger channel is normal

open, and there will not be alarm.

6. It has the liquid crystal display function and can describe the channel operation in intuitive words.

1.4 Electronic control system

The electronic control system of the OP1000 series is mainly composed of the reader, the master

control panel, the access controller, the infrared sensor, the direction indicator and the alarm.

Reader: The reader reads the data in the card and sends it to the controller.

Access control panel: Receive the information collected by the card reader, make judgment, transmit

the controlling signal, and control the switch of the brake machine.

Master control panel: The master control panel is the system’s control center that receives signals

from the reader and the photoelectric switch. It performs logical judgment and processing of such

signals, and sends executive commands to the direction indicator, the electric motor and the alarm.

Infrared sensor: It detects the position of a pedestrian, and triggers alarm warning when illegal

behaviours occur.

Direction indicator: This indicator displays the current status of the sign at the lane, and directs the

pedestrian to pass through the lane in a safe and orderly manner.

Alarm: The alarm gives an alerting sound when the system detects any unauthorized entry.

OP1000 series User Manual 3

1.5 Specifications

Dimension (mm) OP1000 Series: L=500, W=180, H=1000

OP1200 Series: L=500, W=180, H=1000

Communication RS485 Input voltage AC100~240V, 50-60Hz

Input control signal Switching signal Output voltage DC 24V 5A,

DC 12V 3A

Time of opening/

closing 5 s (adjustable) Passage rate Maximum 30/minute

Temperature -28℃- 60℃Relative humidity 20% - 95%

(Non-condensing)

Infrared sensor 3 Working environment Indoor

4OP1000 series User Manual

2. Electrical test before installation

Steps of the test:

1)Connect the machine with a temporary test cable with input power AC 100 ~ 240V adaptive

(Note: must be grounded).

2)Turn on the built-in air switch of the brake and wait for 10 seconds to let the brake completes the

self-check procedure.

3)Make sure the brake is working properly and check the LED indicator. If all goes well, you can

start the civil installation program. In case of any abnormality, please contact your seller.

3. Electrical and civil installation

3.1 Equipment installation condition and position

Equipment installation conditions

The ground base must be concrete to ensure the expansion screws are firmly fixed. If you do not have

this condition, please consult construction or decoration professionals about creating the stable

condition of firmly fixed brake machines, such as piling, laying steel plate, etc.

Equipment installation location

According to the chassis space ratio, determine the installation location. For details, please refer to

Figures 3-1 and 3-2.

Decision on the installation plan and composition of a single or multiple intelligent

management channels

There must be a distance of 100mm between the chassis and the wall for opening the top cover of

the machine to perform maintenance and adjustment. The master and slave devices of OP1000

model can form a single channel or dual channels, as shown in Figures 3-1 and 3-2.

OP1000 series User Manual 5

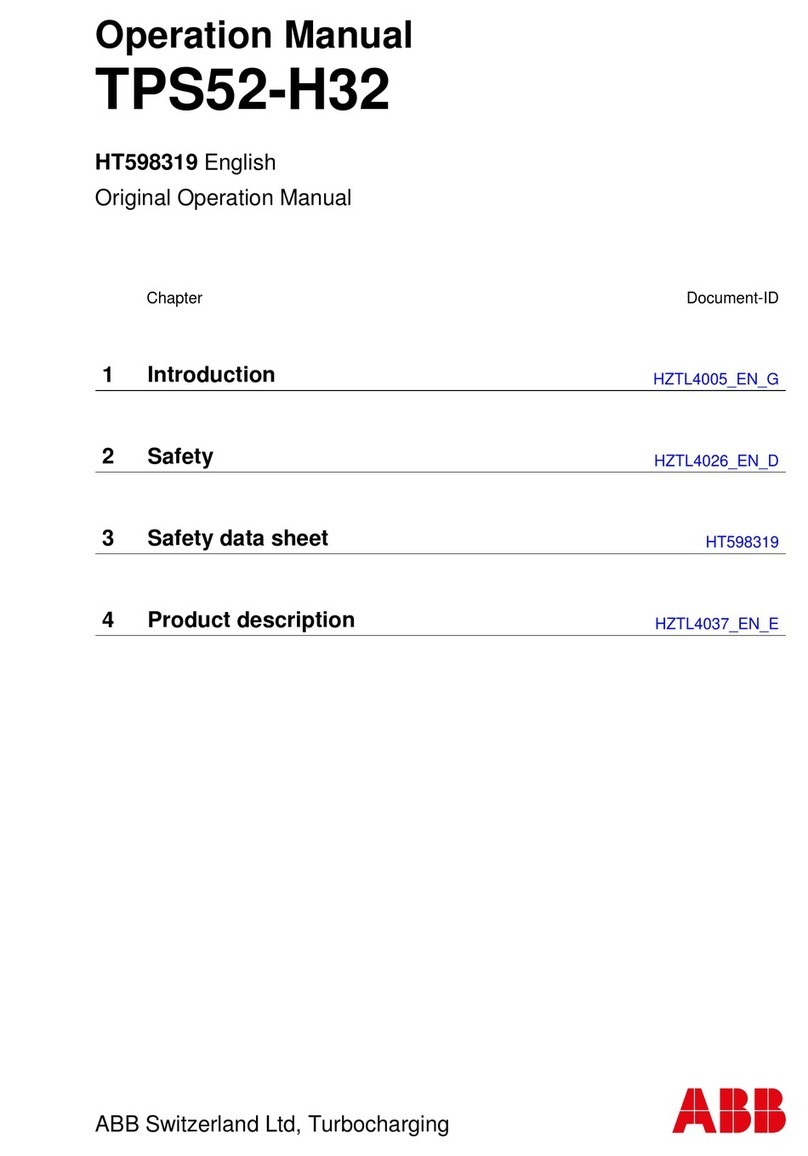

Figure 3-1 OP1000-series single channel

Figure 3-2 OP1000-series dual channel

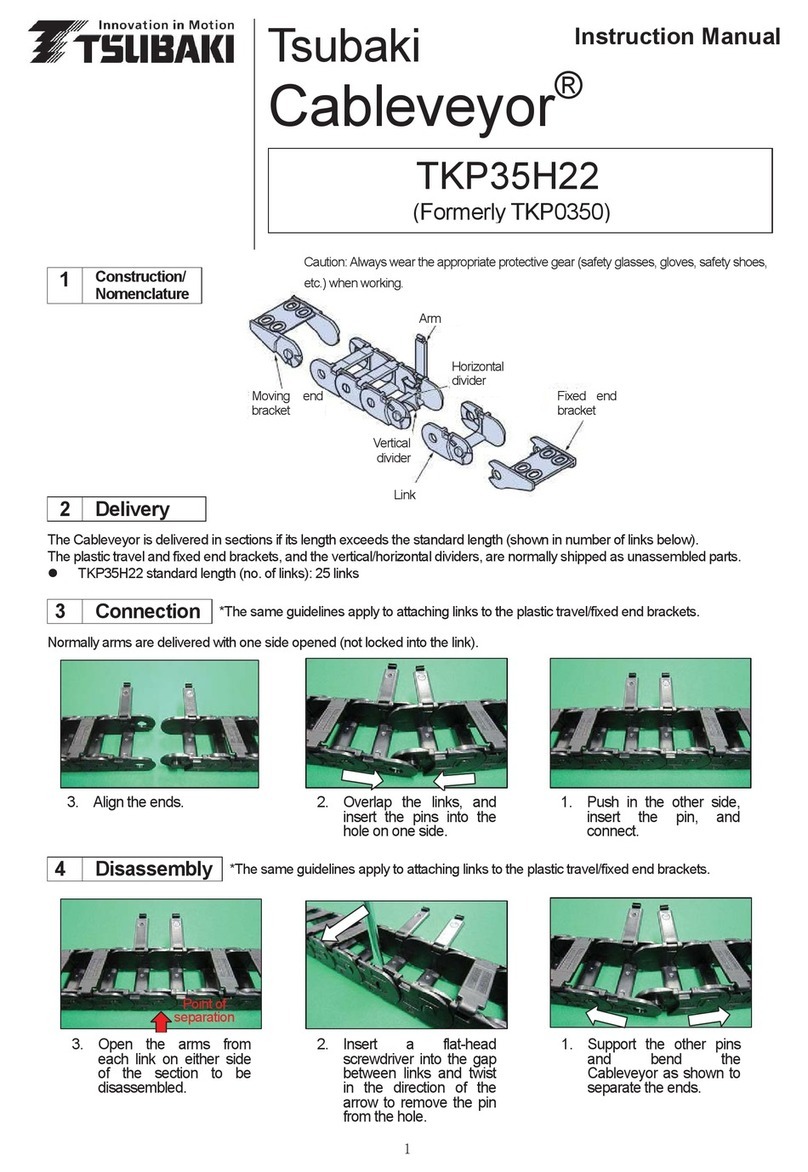

3.2 Cables installation

For the outlet of buried cable, please refer to the locations of the installation holes illustrated in Figure

3-3. The input voltage of this machine is AC100-120V/200-240V and its master and slave are

connected with a 6-core connection wire. When installing this swing barrier turnstile, you only need

to connect it to the corresponding ports. Note that the PVC conduits must be buried 100mm under

180.00 180.00

600.00

1160.30

100.00 100.00

100.00

φ25PVCpip

600.00 600.00

180.00

180.00 180.00

100.00

100.00

100.00

1940.60

φ25PVCpip φ25PVCpip

6OP1000 series User Manual

the ground, with the height of the exposed part not exceeding 100mm. In addition, the conduit

outlet is bent back to prevent ingress of water into the conduit.

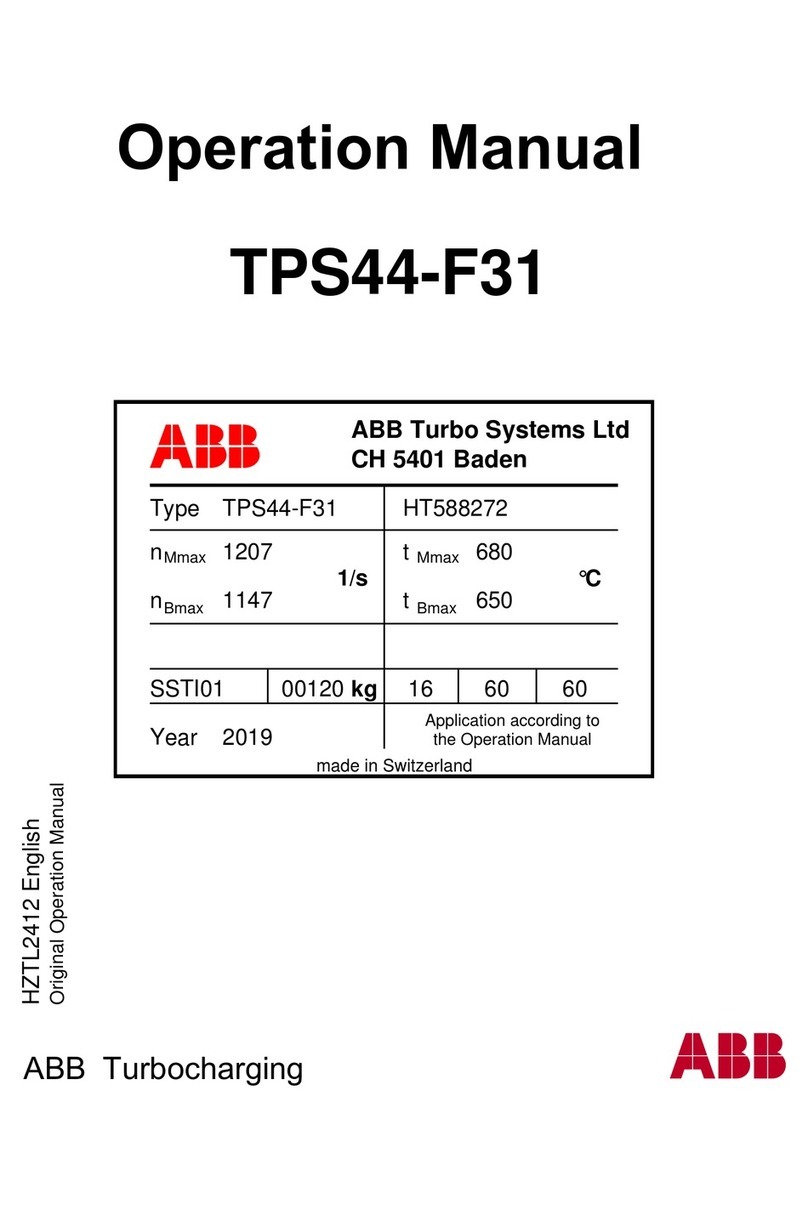

Figure 3-3

3.3 Equipment installation and fixing

Mark the screw hole centre of the stand, and the edge of the chassis base on the ground according to

the size as shown in Figure 3-3. Use a hammer drill to drill M12 screw holes and fix the screws

accordingly. Place the swing barrier turnstile according to the size and position as shown in the figure

before installation and fixing. Connect the online cables and perform the power-on test. Tighten the

screws after the test is passed.

3.4 Set up a warning line

It is recommended to mark a warning line on the ground, as shown in Figure 3-4, after the machine is

installed, so as to instruct the pedestrian to stand behind the warning line during card swiping:

Figure 3-4

120.00

380.00

600.00

120.00

OP1000 series User Manual 7

4. Equipment wiring and debugging

4.1 Internal wiring diagram

Figure 4-1

4.2 Master and slave wiring diagram

The connection between the master and the slave is illustrated with red lines in Figure 4-1.

8OP1000 series User Manual

5. Menu Introduction

5.1 Function introduction

1. After powered on, the LCD screen on the control board will display a default status,

which represents the current work mode.

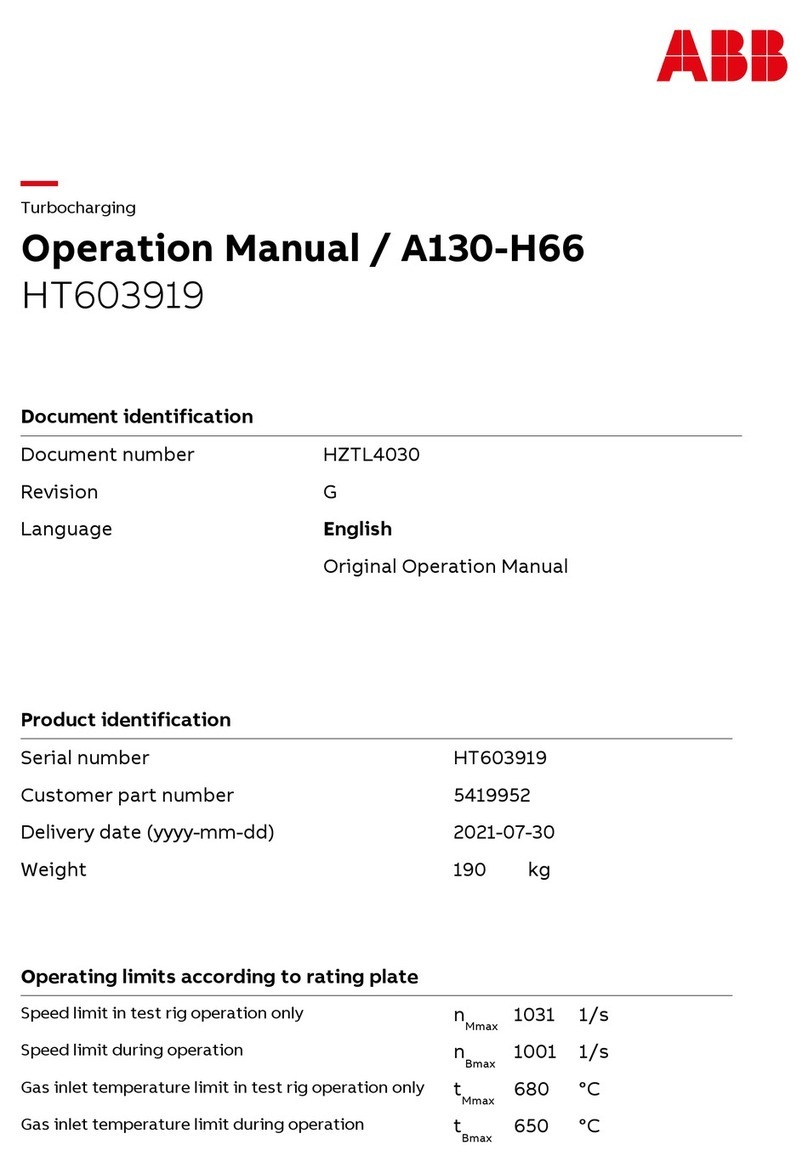

2. There are 4 buttons, namely, “UP”, “DOWN”, “ENT” and “ESC” on the control board, as

shown in Figure 5-1:

UP: to move a menu item upwards or increase the value.

DOWN: to move a menu item downwards or decrease the value.

ENT: to enter menu setting item or confirm the current modified value.

ESC: to return to the previous menu or to cancel the current operations.

Figure 5-1

5.2 Menu introduction

1. Open duration (Press ‘ENT’ to modify)

After the gate is opened, it will automatically close if no one passes through within a certain time

duration. The default value is 5 seconds.

The current value is: xxx. Press “UP” or “DOWN” to change the value, then press “ESC” to return.

The setting is completed. Press “ESC” to exit.

OP1000 series User Manual 9

2. Opening mode (Press ‘ENT’ to modify)

You may unlock by card swiping or infrared induction. There are four available choices as listed below.

The “Freedom” mode represents unlock by infrared induction.

0: Bi-direction card swiping. (→C, C←)

1: Card swiping on the left. (→C, F←)

2: Card swiping on the right. (→F, C←)

3: Bi-direction controlled by the IR sensor. (→F, F←)

The current value is: xxx. Press “UP” or “DOWN” to change the value, then press “ESC” to return. The

default value is 0.

The setting is completed. Press “ESC” to exit.

3. False direction entry (Press ‘ENT’ to modify)

Set whether to trigger the alarm when reverse intrusion occurs.

The current value is: xxx. Press “UP” or “DOWN” to change the value, then press “ESC” to return. The

default setting is enabled.

The setting is completed. Press “ESC” to exit.

4. Anti-tailgate (Press ‘ENT’ to modify)

Set whether to enable following intrusion detection.

The current value is: xxx. Press “UP” or “DOWN” to change the value, then press “ESC” to return. The

default setting is enabled.

The setting is completed. (cancel or set). Press “ESC” to exit.

5. Memory function (Press ‘ENT’ to modify)

Whether to record the number of swiping. When the function is enabled, swipe several times to

record several permissions.

The current value is: xxx. Press “UP” or “DOWN” to change the value, then press ‘ESC’ to return. The

default setting is disabled.

10 OP1000 series User Manual

6. Firefighting signal setting (Press ‘ENT’ to modify)

Select whether to enable the fire green channel function and select with what signal triggered.

0 — Unavailable

1 — Pulse signal

2 — Continuous signal

The current value is: xxx. Press “UP” or “DOWN” to change the value, then press ‘ESC’ to return. The

default value is 0.

The setting is completed. Press “ESC” to exit.

Note: please set the same value for the master and slave devices.

7. System working mode (Press ‘ENT’ to modify)

1 — Working mode

2 — Factory Reset

There are two modes available. The working mode is the normal working mode of the machine, while

the factory reset mode is to restore brake parameters to default values. The default value is 1. Device

normally working.

8. Volume setting (Press ‘ENT’ to modify)

Adjustable range: from 0 to 15

0 is the minimum value; 15 is the maximum value.

The current value is: xxx. Press “UP” or “DOWN” to change the value, then press ‘ESC’ to return. The

default value is 8.

The setting is completed. Press “ESC” to exit.

9. Version

Version information of the device.

5.3 Operation and instruction of menu

Press the ENT button, enter the password input interface. The default password is: UP, UP, DOWN,

DOWN, DOWN, DOWN. You may press the ESC button to erase the last input. After entering the

OP1000 series User Manual 11

menu, press UP or DOWN to choose a menu item, then press ENT to enter the interface and adjust

such function or value.

12 OP1000 series User Manual

6. Product Maintenance

6.1 Chassis maintenance

The chassis is made up of 304 stainless steels. There may be rust stains on its surface after being used

for a long time. Regularly sand the surface along the grain softly and carefully. Coat the surface with

anti-rust oil. Do not cover the infrared sensor.

6.2 Power maintenance

Cut off power supply before maintenance. Check whether the plug is loose; if yes, tighten it. Do not

change the connection position. Check whether the external power supply is exposed; if yes, timely

wrap it. Also, check whether there is any leakage; if yes, do timely treatment. Check if the technical

parameters of the interface is normal. The aged electronic components should be replaced.

Attention: The maintenance procedure of the swing barrier above must be conducted by

professional personnel. Always cut off the power supply before any maintenance and repair. Ensure

all operations are safely performed.

This manual suits for next models

5

Table of contents

Other ZKTeco Industrial Equipment manuals