Baumer Table of contents

V1.0 | IDC200 Operating Manual iii

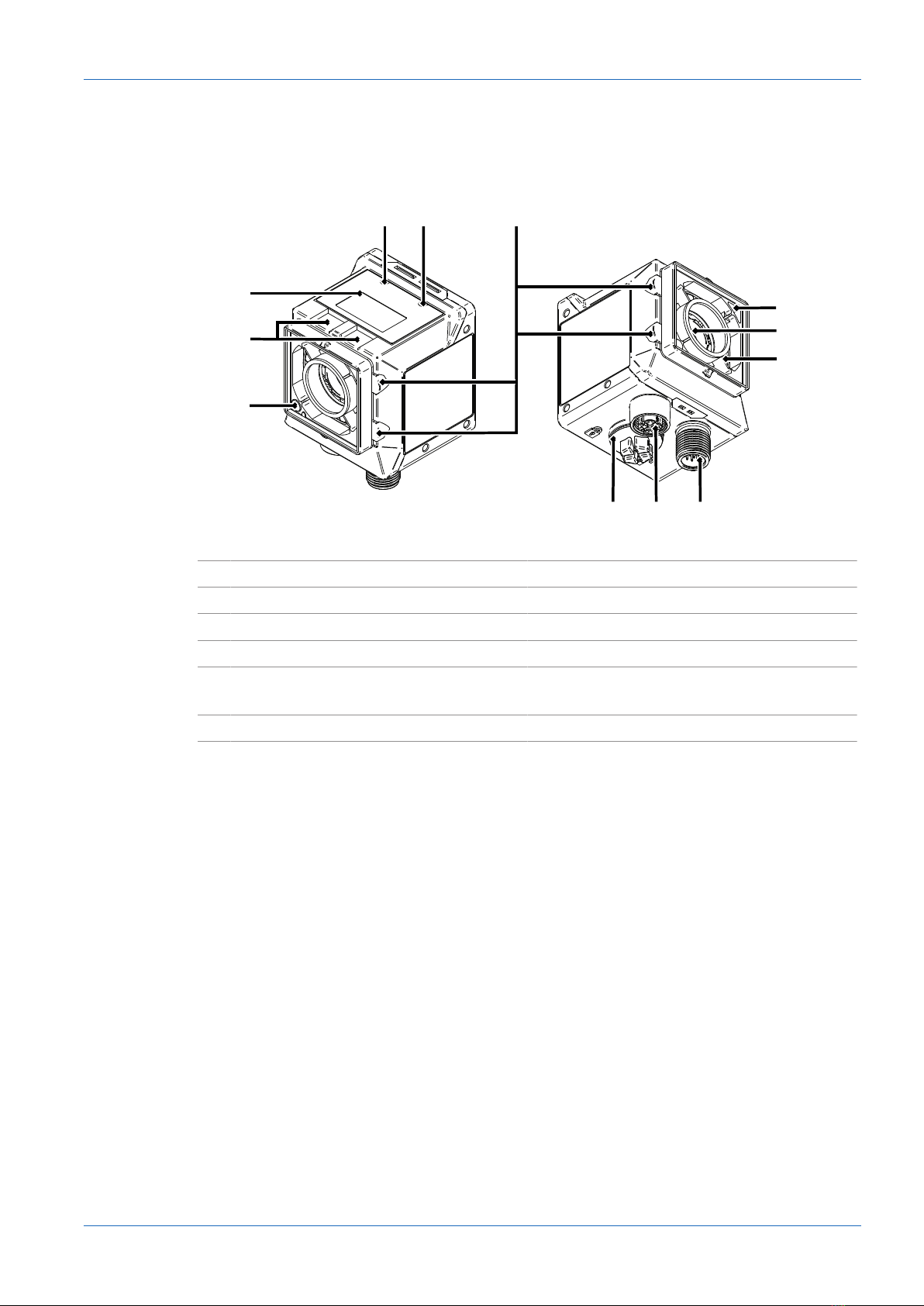

5.4 Mounting the sensor............................................................................................................................ 32

5.5 Accessories (not included) .................................................................................................................. 33

6 Electrical installation .................................................................................................................................. 34

6.1 General instructions for electric installation......................................................................................... 34

6.2 Connecting the sensor to the electrical system................................................................................... 34

6.3 Pin assignment.................................................................................................................................... 35

6.4 Wiring .................................................................................................................................................. 35

7 Commissioning ........................................................................................................................................... 36

7.1 Connecting the sensor to the PC ........................................................................................................ 36

7.1.1 Allocating an IP address to the PC ....................................................................................... 36

7.1.2 Determining the sensor's IP address .................................................................................... 38

8 Web interface............................................................................................................................................... 39

8.1 Functions and tasks ............................................................................................................................ 39

8.2 User interface description ................................................................................................................... 39

8.2.1 Header .................................................................................................................................. 40

8.2.2 Menu bar............................................................................................................................... 41

8.2.3 Parametrisation area............................................................................................................. 41

8.2.4 Footer.................................................................................................................................... 42

8.2.5 Visualisation area.................................................................................................................. 42

8.2.6 Measured values................................................................................................................... 43

8.3 Monitoring mode ................................................................................................................................. 44

8.4 Parameterization mode ....................................................................................................................... 45

8.4.1 Mode Parameterization Tools............................................................................................... 45

8.4.1.1 Measuring tool: Image...................................................................................... 47

8.4.1.2 Measuring tool: Barcode .................................................................................. 48

8.4.1.3 Measuring tool: Matrix code ............................................................................. 50

8.4.1.4 Auxiliary tool: Code check ................................................................................ 52

8.4.1.5 Auxiliary tool: Quality Check............................................................................. 53

8.4.1.6 Annex: Quality features for barcode and matrix code ...................................... 54

8.4.2 Mode Parameterization Communication............................................................................... 56

8.4.2.1 Communication: Data telegram........................................................................ 56

8.4.2.2 Communication: Digital output ......................................................................... 59

8.4.3 Job mode .............................................................................................................................. 59

8.5 Device configuration mode.................................................................................................................. 60

8.6 Diagnostic data mode ......................................................................................................................... 62

8.7 Statistical functions ............................................................................................................................. 63

9 Preventive maintenance ............................................................................................................................. 65

9.1 Cleaning the sensor ............................................................................................................................ 65

10 Troubleshooting .......................................................................................................................................... 66

10.1 Return and repair ................................................................................................................................ 66

10.2 Support................................................................................................................................................ 66

11 Technical data ............................................................................................................................................. 67