Page 3

ENGLISH

Zodiac®JXi™Gas-Fired Pool & Spa Heater |Installation & Operation Manual

Section 1. General Information

This manual provides installation and operation

instructions for the Zodiac JXi pool and spa gas heater

product line.

Read the installation and operation instructions

completely before proceeding with the

installation.

1.1 Technical Assistance

Web: www.zodiac.com.au Phone: 1300 763 021

1.2 Warranty

This heater is sold with a limited factory warranty.

Details are included with this heater or for full terms and

conditions please go to www.zodiac.com.au.

All warranty issues should be resolved with your

Zodiac dealer or place of purchase. Claims must

include the heater serial number and model (this

information can be found on the rating plate),

installation date, and name of the installer. Shipping

costs are not included in the warranty coverage.

The warranty does NOT cover damage caused by

improper assembly, installation, operation or eld

modication. Also, any damage to the heat exchanger

caused by improper water chemistry will NOT be

covered by the warranty.

NOTE: Keep this manual in a safe place for future reference when

inspecting or servicing the heater.

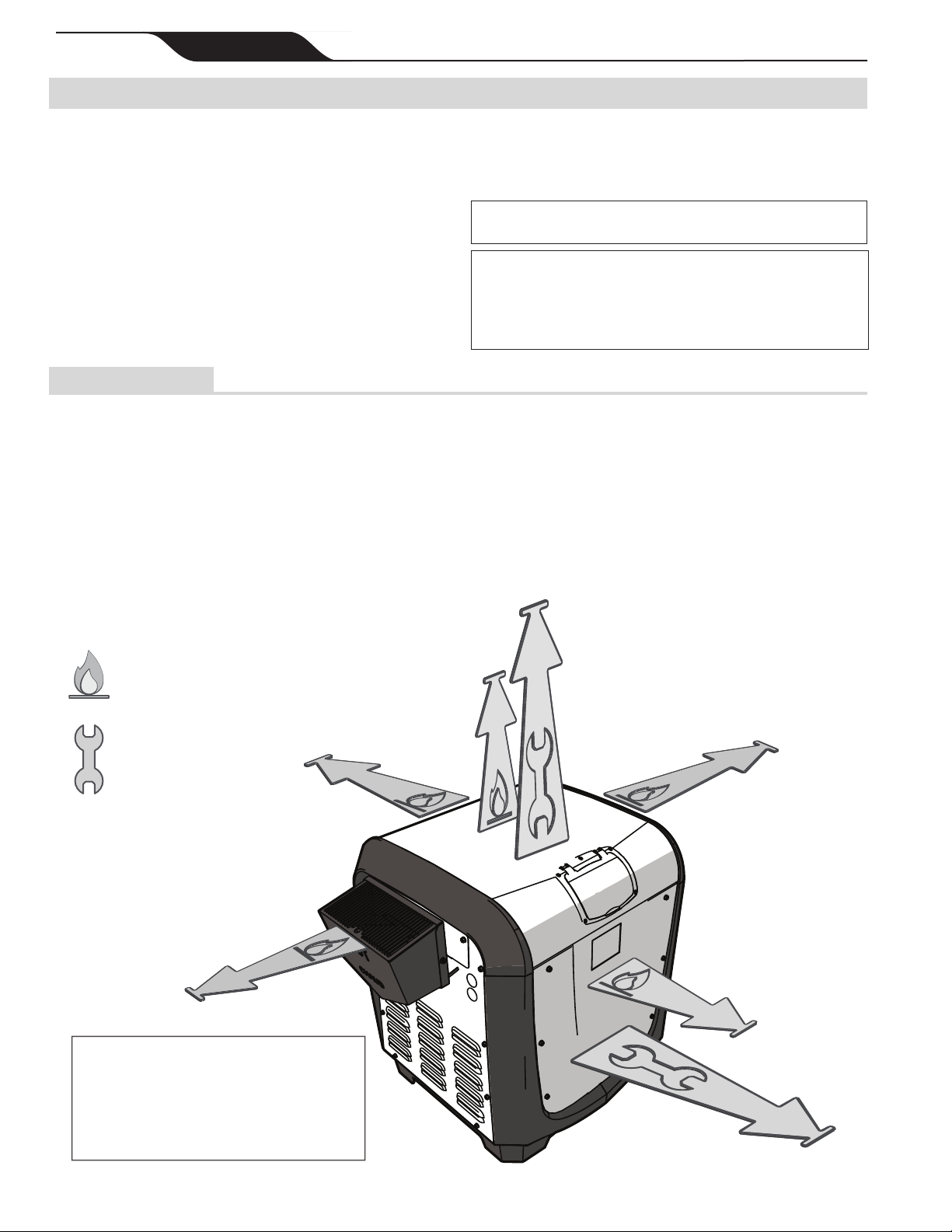

1.3 Consumer Information and Safety

The heater is designed and manufactured to provide

many years of safe and reliable service when

installed, operated, and maintained according to

the information in this manual and the installation

codes referred to throughout. Be sure to read

and comply with all warnings and cautions.

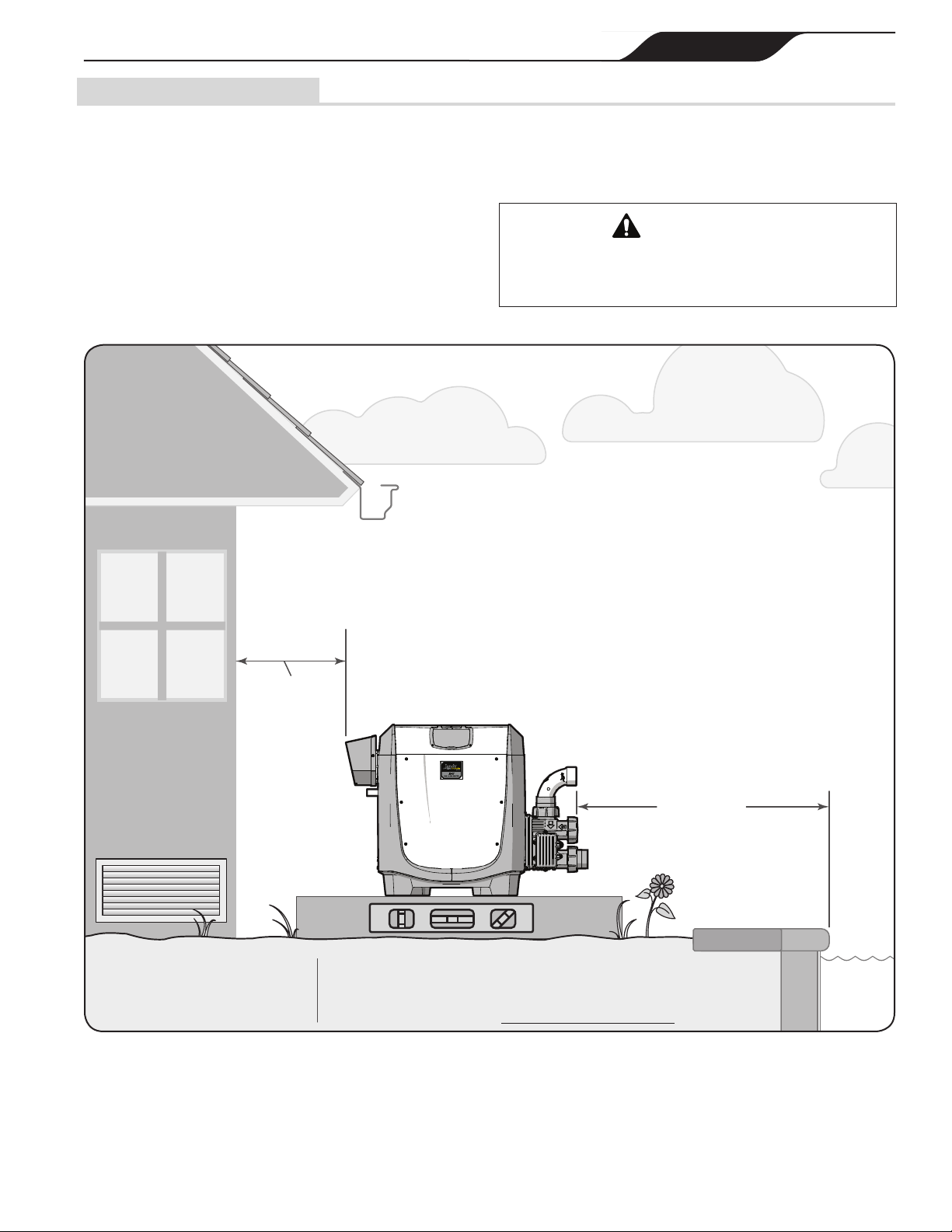

WARNING

Improper installation or maintenance can cause nausea or asphyxi-

ationfromcarbonmonoxideinuegaseswhichcouldresultin

severe injury, or death. For indoor installations, as an additional

measure of safety, Zodiac Group Australia Pty, Ltd. strongly recom-

mends the installation of suitable Carbon Monoxide detectors in

the vicinity of this appliance and in any adjacent occupied spaces.

WARNING

The following “Safety Rules for Hot Tubs,” recommended by the

U.S. Consumer Product Safety Commission, should be observed

when using the spa. Consult heater operation and installation

instructions for water temperature guidelines before setting tem-

perature.

• Spa or hot tub water temperature should never exceed 40°C

(104°F). 38°C (100°F) is considered safe for a healthy adult. Spe-

cial caution is recommended for young children.

• The drinking of alcoholic beverages before or during spa or

hot tub use can cause drowsiness which could lead to uncon-

sciousness, and subsequently result in drowning.

• Pregnant women take note! Soaking in water above 38.5°C

(102°F)cancausefetaldamageduringtherstthree(3)months

of pregnancy (which could result in the birth of a brain-damaged or

deformed child). If pregnant women are going to use a spa or hot

tub, they should make sure the water temperature is below 38°C

(100°F) maximum.

• The water temperature should always be checked with an ac-

curate thermometer before entering a spa or hot tub. Temperature

controls may vary by as much as 1C°/1F°.

• Persons with a medical history of heart disease, diabetes, cir-

culatory or blood pressure problems should consult their physician

before using a hot tub or spa.

• Persons taking any medication which induces drowsiness

(e.g., tranquilizers, antihistamines, or anticoagulants) should not

use spas or hot tubs.

• Prolonged immersion in hot water can induce hyperthermia.

• Hyperthermia occurs when the internal body temperature

reaches a level several degrees above the normal body tem-

perature of 37°C (98.6°F). Symptoms include dizziness, fainting,

drowsiness, lethargy, and an increase in the internal body tempera-

ture. The effects of hyperthermia include:

• Lack of awareness of impending hazard

• Failure to perceive heat

• Failure to recognize need to leave spa

• Physical inability to leave spa

• Fetal damage in pregnant women

• Unconsciousness resulting in a danger of drowning

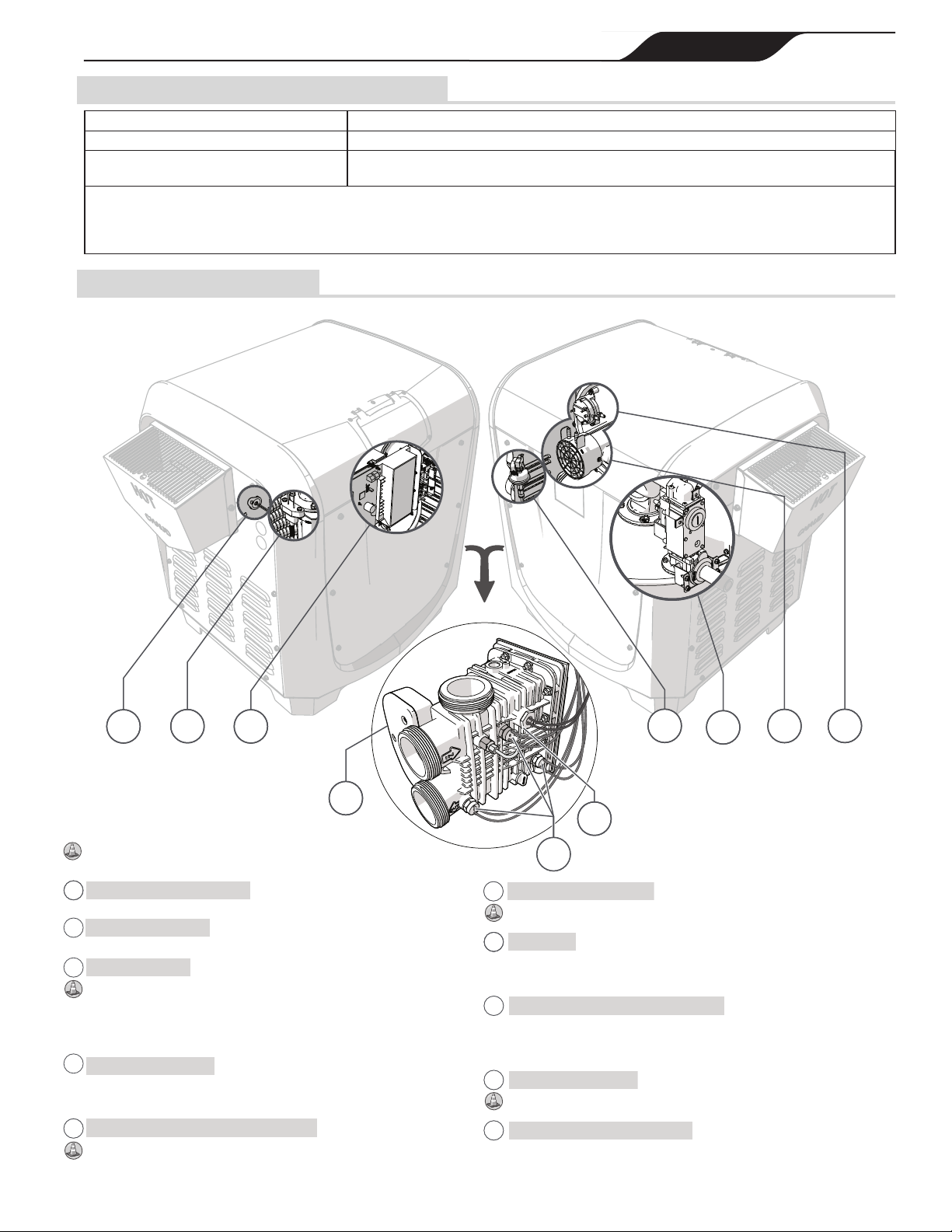

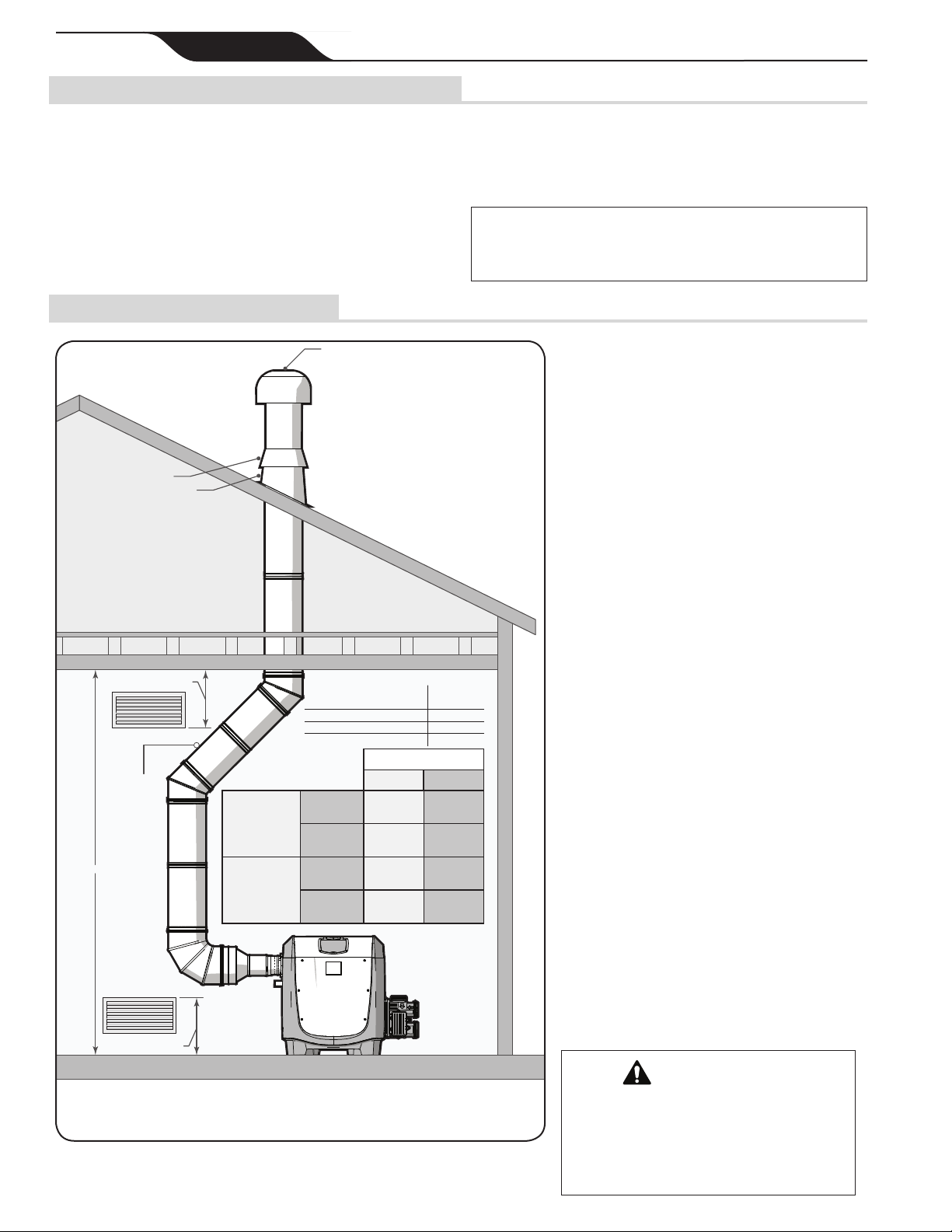

1.4 General Operation Description

The blower draws air and fuel through specially designed

orices, delivering a precise mixture to the burner,

located inside the sealed combustion chamber. Water

ows through the heat exchanger, which surrounds the

burner transferring the heat to the water. Exhaust gases

are then directed through a duct where it is vented to the

atmosphere.