2

© Copyright 2021. All rights reserved.

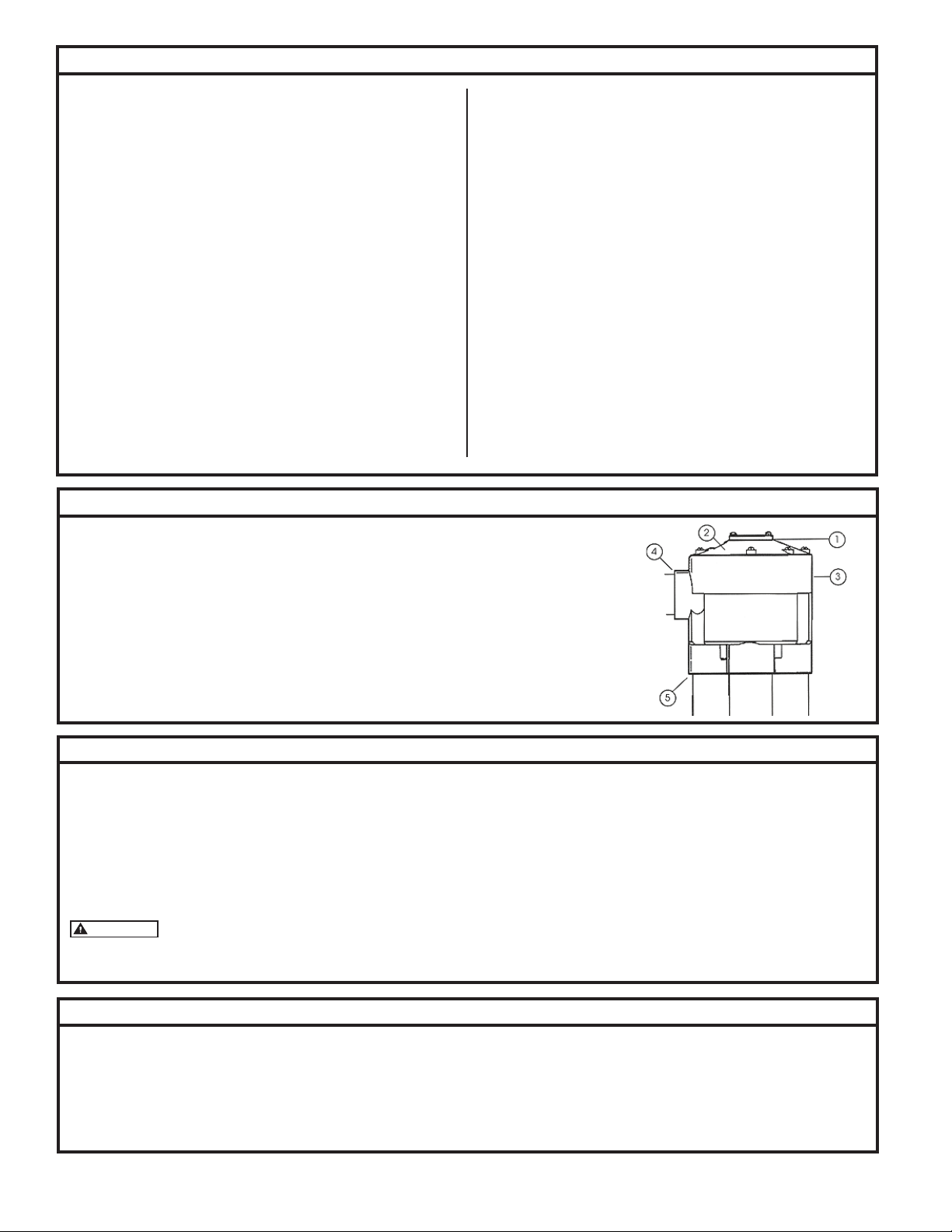

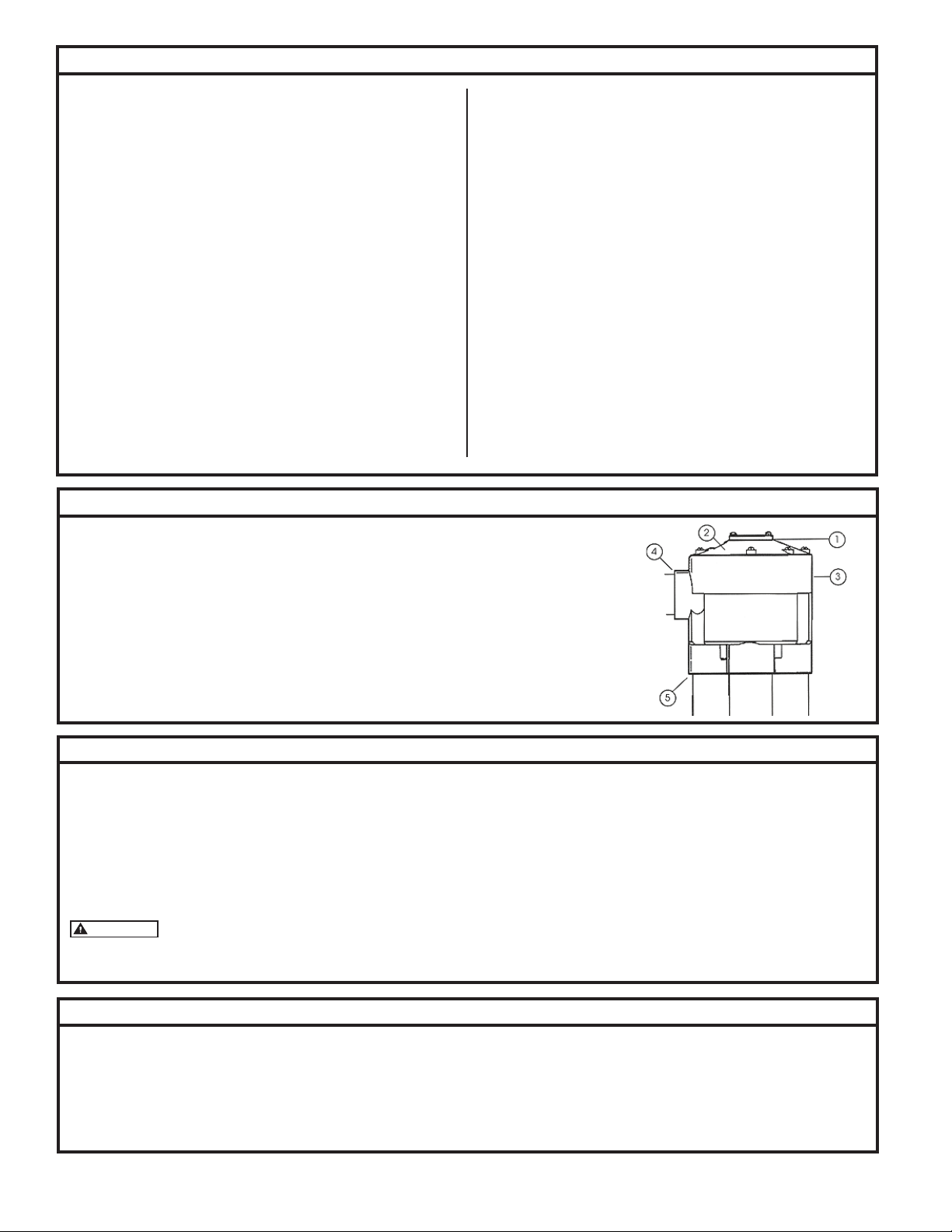

1. Cam - Used to index the valve to the next zone and controls how many outlets are to be used. May

be changed to increase or decrease number of operating zones. Secured to valve top with two cam

retaining screws.

2. Valve Top - A high strength ABS plastic top secured with seven valve top retaining screws.

3. Valve Body - A high strength ABS plastic housing.

4. Inlet - Allows for slip and glue connection of a 1-1/4' pipe.

5. Outlets - 4 outlet model - 1-1/4 PVC pipe / 6 outlet model 1' PVC pipe.

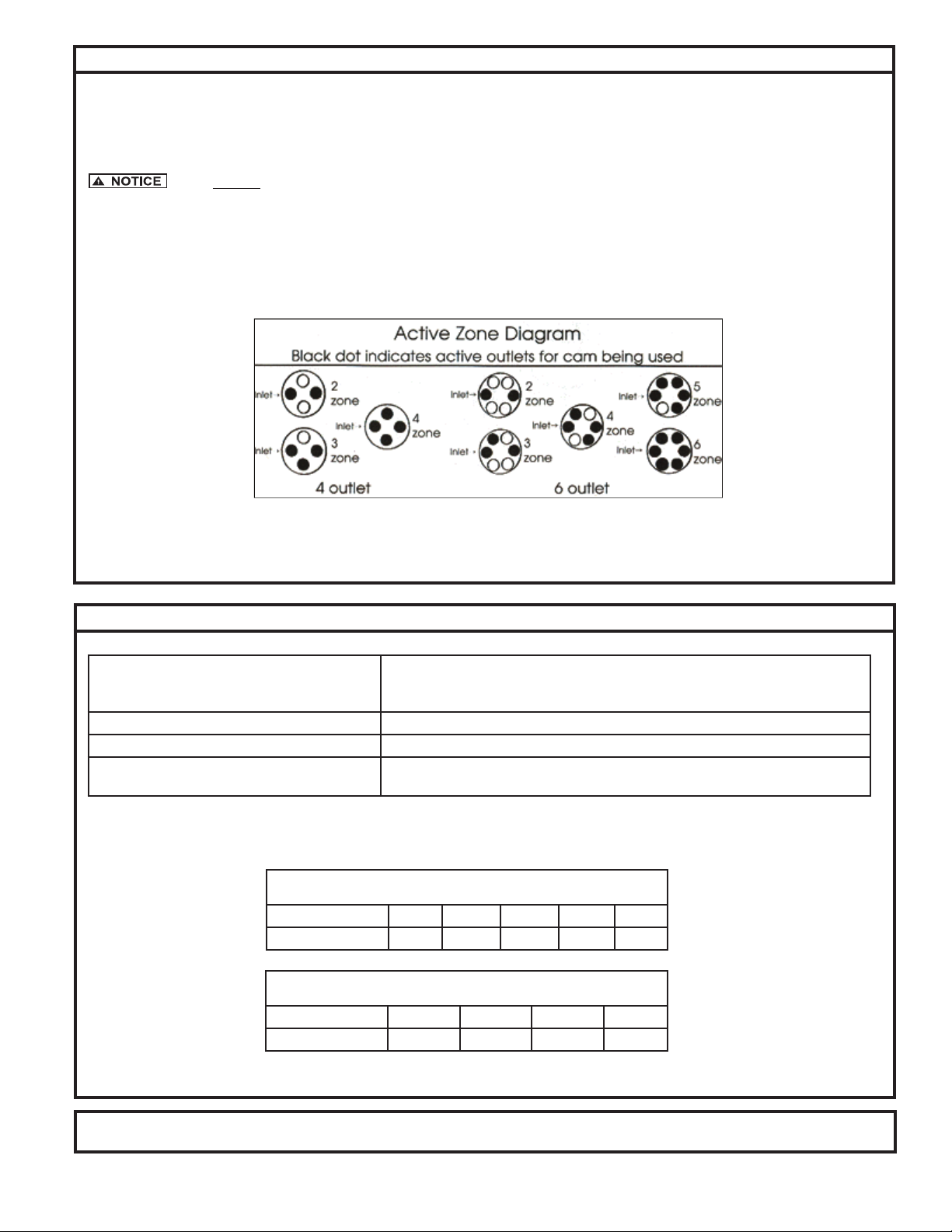

Replacement cams are available to increase or decrease the number of operating outlets on the 4000 Series Automatic Multizone Valve.

BE SURE YOU HAVE THE CORRECT REPLACEMENT CAM. Except for the two zone cam, cams for the four outlet valves and the six outlet valves are NOT inter-

changeable. The correct bottom to be used is marked on the top of the cam.

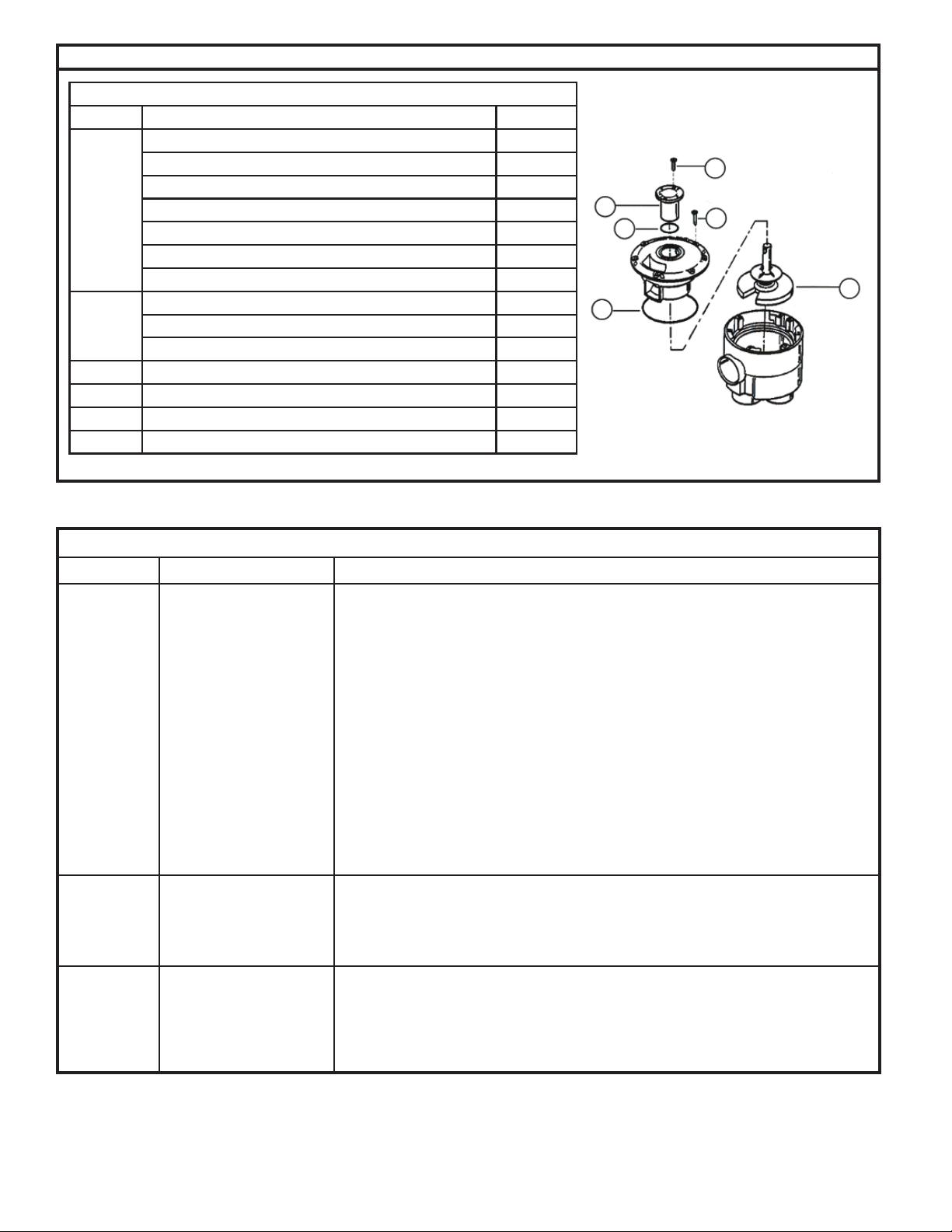

To remove cam, remove two cam retaining screws and pry up gently with screwdriver.

To install a new cam, partially insert the cam into the valve top and rotate it counterclockwise while applying gentle downward pressure. This allows the upper

lug on the stem in the valve to slip into the cam. The cam should slip into place easily. When installed correctly, the cam should slide down in place with NO

tendency to spring back. Improper installation will cause the valve to jam and prevent the valve from advancing properly.

CAUTION

Cams for operation of fewer than the full number of outlets have one or more camming slots blocked. Because of this, it is important to

make sure that the cam is lowered in the valve so that the lug on the stem in the valve is inserted into an open cam slot in the cam.

Prior to installation of 4000 Series Automatic Multizone Valve, make sure that the system is designed using adequate pipe sizes to ensure maximum perfor-

mance of the valve.

For installation with large terrain elevations, or applications with high lift requirements, the valve should be installed at the highest point in the system, or

check-valves should be installed near the valve in the elevated lines to prevent the back ow of water from the higher locations to the lower zones.

Limited Warranty

Manufacturer warrants, to the purchaser and subsequent owner during

the warranty period, every new product to be free from defects in material

and workmanship under normal use and service, when properly used and

maintained, for a period of one year from date of purchase by the end user, or

18 months from date of original manufacture of the product, whichever comes

rst. Parts that fail within the warranty period, one year from date of purchase

by the end user, or 18 months from the date of original manufacture of the

product, whichever comes rst, that inspections determine to be defective

in material or workmanship, will be repaired, replaced or remanufactured

at manufacturer's option, provided however, that by so doing we will not be

obligatedtoreplace anentireassembly,theentire mechanismor thecomplete

unit. No allowance will be made for shipping charges, damages, labor or

other charges that may occur due to product failure, repair or replacement.

Thiswarranty does not apply to and there shall be no warrantyfor any material

orproductthathas beendisassembledwithoutprior approvalofmanufacturer,

subjected to misuse, misapplication, neglect, alteration, accident or act of

God; that has not been installed, operated or maintained in accordance with

manufacturer's installation instructions; that has been exposed to outside

substances including but not limited to the following: sand, gravel, cement,

mud,tar, hydrocarbons, hydrocarbonderivatives (oil, gasoline, solvents, etc.),

or other abrasive or corrosive substances, wash towels or feminine sanitary

products, etc. in all applications other than in efuent pumping applications.

The warranty set out in the paragraph above is in lieu of all other warranties

expressed or implied; and we do not authorize any representative or other

person to assume for us any other liability in connection with our products.

Contact manufacturer at, 3649 Cane Run Road, Louisville, Kentucky 40211,

Attention: Customer Support Department to obtain any needed repair or

replacement of part(s) or additional information pertaining to our warranty.

MANUFACTURER EXPRESSLY DISCLAIMS LIABILITY FOR SPECIAL,

CONSEQUENTIAL OR INCIDENTAL DAMAGES OR BREACH OF EXPRESSED

OR IMPLIED WARRANTY; AND ANY IMPLIED WARRANTY OF FITNESS FOR

A PARTICULAR PURPOSE AND OF MERCHANTABILITY SHALL BE LIMITED

TO THE DURATION OF THE EXPRESSED WARRANTY.

Some states do not allow limitations on the duration of an implied warranty,

so the above limitation may not apply to you. Some states do not allow the

exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

This warranty gives you specic legal rights and you may also have other

rights which vary from state to state.

Major Components

Cam Replacement Instructions

Valve Installation Instructions