C9154 Installation - pg. 9

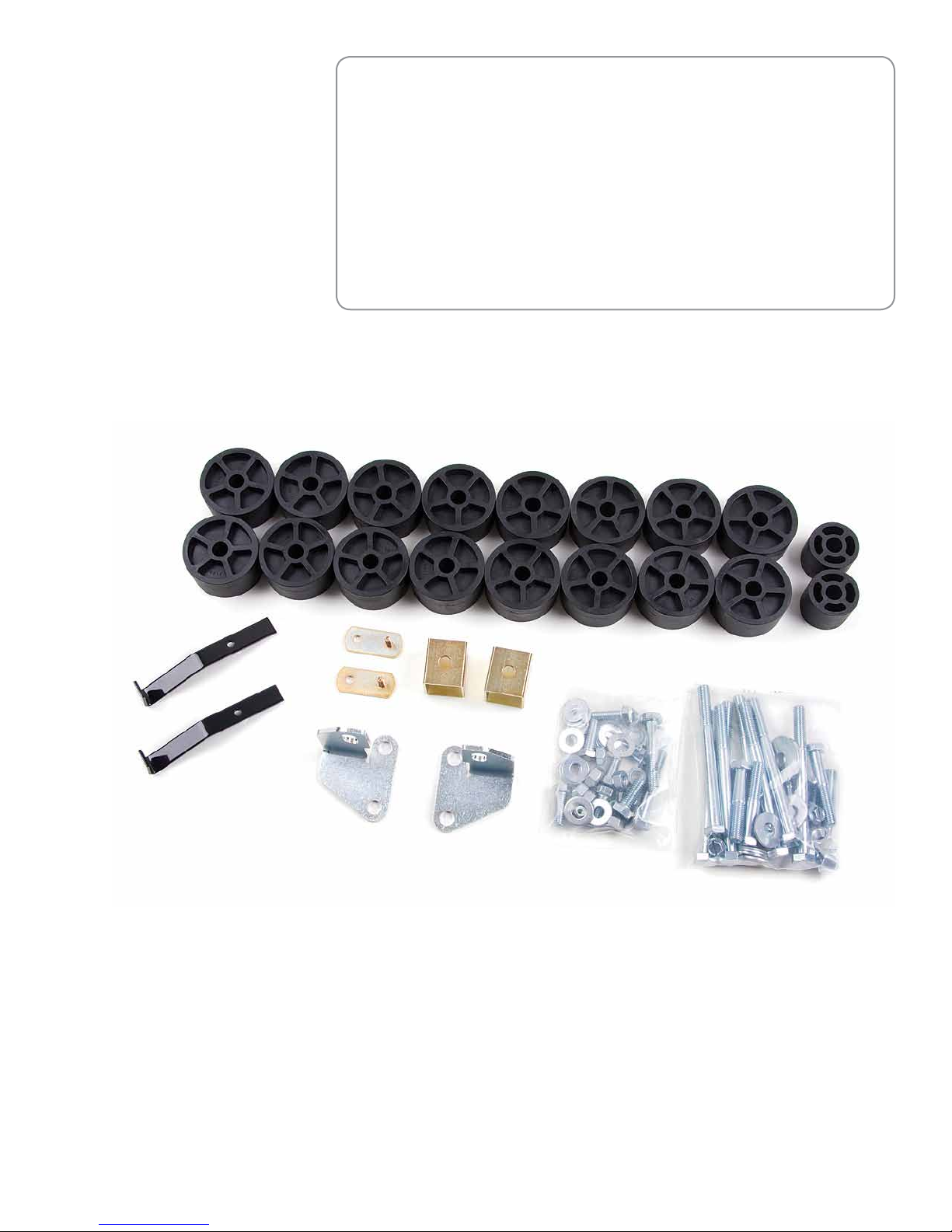

Figure 14

»caB liFt

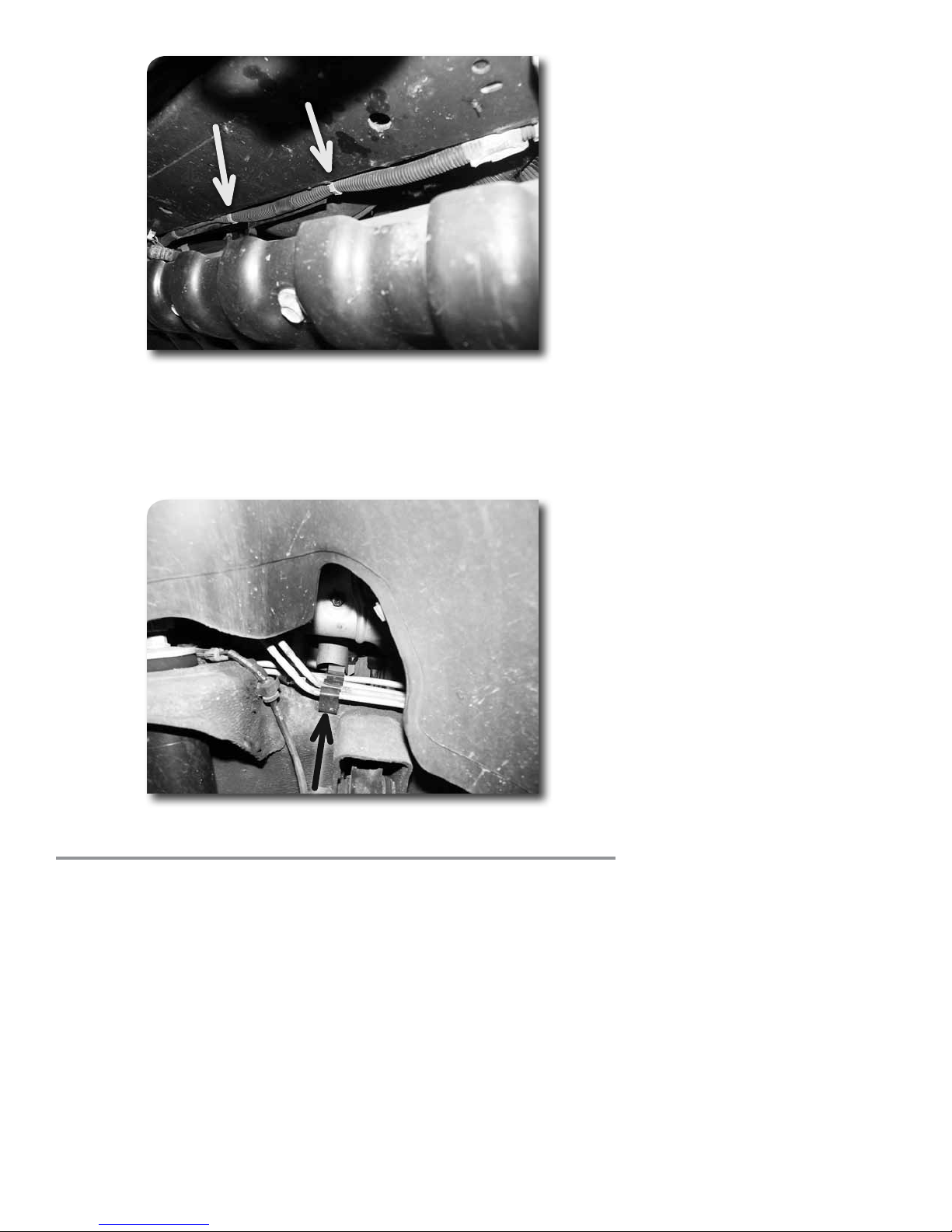

19. Check for any other wires, hoses, cables, etc that may not have enough slack for

1.5” of body lift. Disconnect or reroute these parts as necessary.

20. Loosen but do not remove all cab mount bolts. All mounting bolts thread up into

the cab except the two front bolts which are mounted downward. The front bolts

are accessed through a hole in the body.

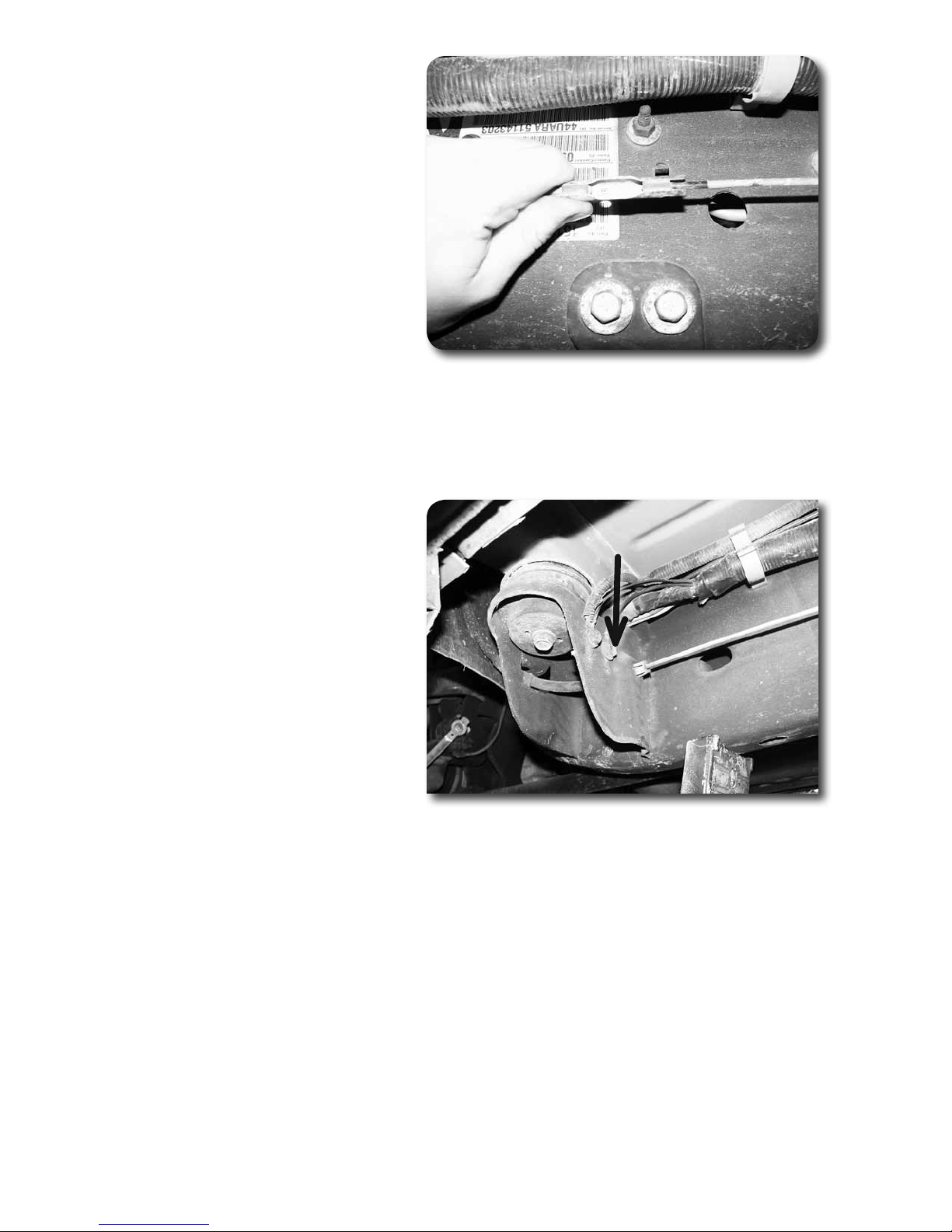

21. Remove the passenger’s side body bolts. Place a hydraulic jack (with wooden

block) under the passenger’s side so that the weight is evenly distributed on the

jack. Slowly raise body, checking for any wires or hoses that may be binding or

stretching. Lift the body just high enough to install the large 3" diameter body

spacers.

22. Install 12mm x 140mm bolts and 7/16” USS washers in all the body mounts in

combination with the factory body bushing assemblies. The front mount uses the

thick 1-3/4” diameter washers on the bolt that is installed from the top through

the access hole in the body. Fasten the front bolt with a 7/16” USS washers and

12mm nuts along with the factory bushing assemblies. Do not tighten body

mount bolts at this time.

23. Repeat lift procedure for other side of vehicle.

24. Inspect the body to see that it is properly aligned on the frame and the bed.

Remove each body bolt one at a time and apply Loctite to the threads. Torque all

body mount bolts to 65 ft-lbs.

»Bed liFt

25. Loosen but do not remove all bed mounting bolts (six on short bed, eight on

long).

26. Remove the bolts from one side of the bed. Using a hydraulic jack and a block

of wood, lift the bed just high enough to install the body spacers. Install 12mm

x 70mm bolts and 7/16” washers in the body spacers but do not tighten.

27. Repeat the lifting procedure for the other side of the vehicle. Align the bed to the

cab and tighten all mounting hardware. Use Loctite® on all mounting hardware.

28. Remove the rubber pads from the frame where the bed’s cross members origi-

nally rested (four locations on long beds, two on short beds). Place the metal

body spacers at these locations. Figure 15 Attach the spacers to the frame with

5/16" x 3/4” self-tapping bolts. Tighten hardware to 10 ft-lbs.

Step 22 Note

All body mount hardware is lo-

cated in hardware pack #273.

Step 24 Note

If the vehicle is equipped with

aftermarket step bars that mount

off of the body mounts, longer

mounting bolts may be required in

those locations.

Step 26 Note

All bed mounting hardware is

located in hardware pack #273.

Step 28 Note

5/16" bed spacer hardware is

located in hardware pack #273. It

may be helpful to use the bolts to

tap the holes before installing the

spacer.