、

8

CHK

ADJ

NO. PART NO.

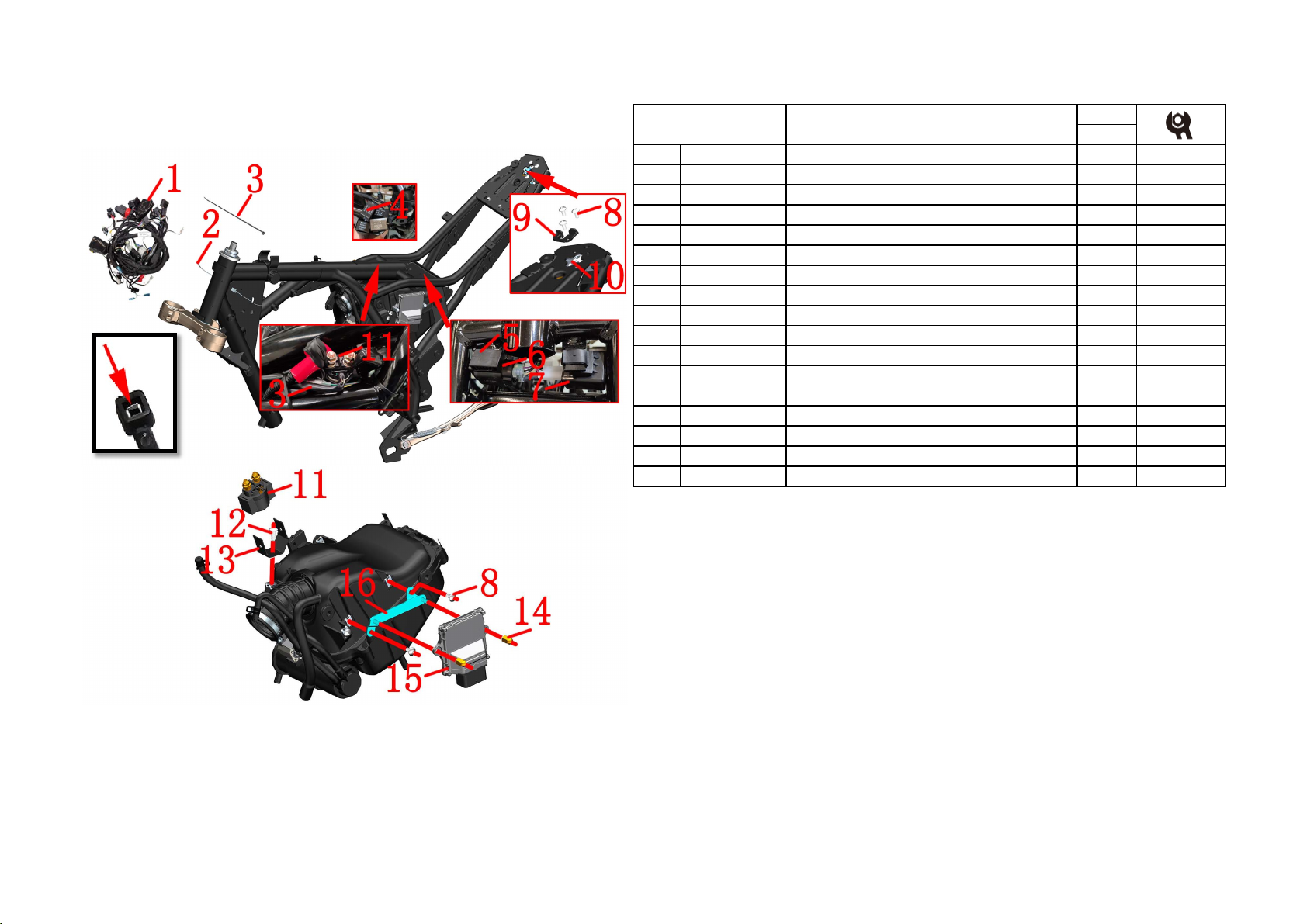

1 1184200-169000 ZT310-V wiring harness assembly (Bosch) 1

2 1224100-030000 Plug cable tie (black 4.8×130) 2

3 1224100-037000 0 level antiflaming binding

(

)

-

S Electronic fuel injection relay 5 KH-1A4T

-

-

-

8 1251100-101000 Non-standard bolt M6×12

(

)

9 1224200-205000 ZT310 electronic cushion lock guide block 1

10 1274100-058000 ZT310 seat lock 1

-

12 1251100-102000 Non-standard bolt M6×16

(

)

13 1274200-171000 ZT310-V relay bracket 1

14 1251300-085093 Non-standard cap nut M6 (environmental color) 2

15 MSE6.0 Controller-ZT180MN 1

【

】

-

Fig.1 FRAME&ELECTRONIC

PARTS COMPONENT Electronic parts COMPONENT-1

:

●Please notice the limit of the bracket when dismantling flasher and dump switch sleeve, beware of

hurting your fingers.

●【1】If the part code is empty, it indicates that the part has multiple states or colors. For specific

states, please find the corresponding state or color in the official website parts. Only the disassembly and

assembly steps are explained here, and the color and status do not affect the disassembly and assembly

process. This description will not be added if there is such a situation later in this manual.

PROCEDURE:

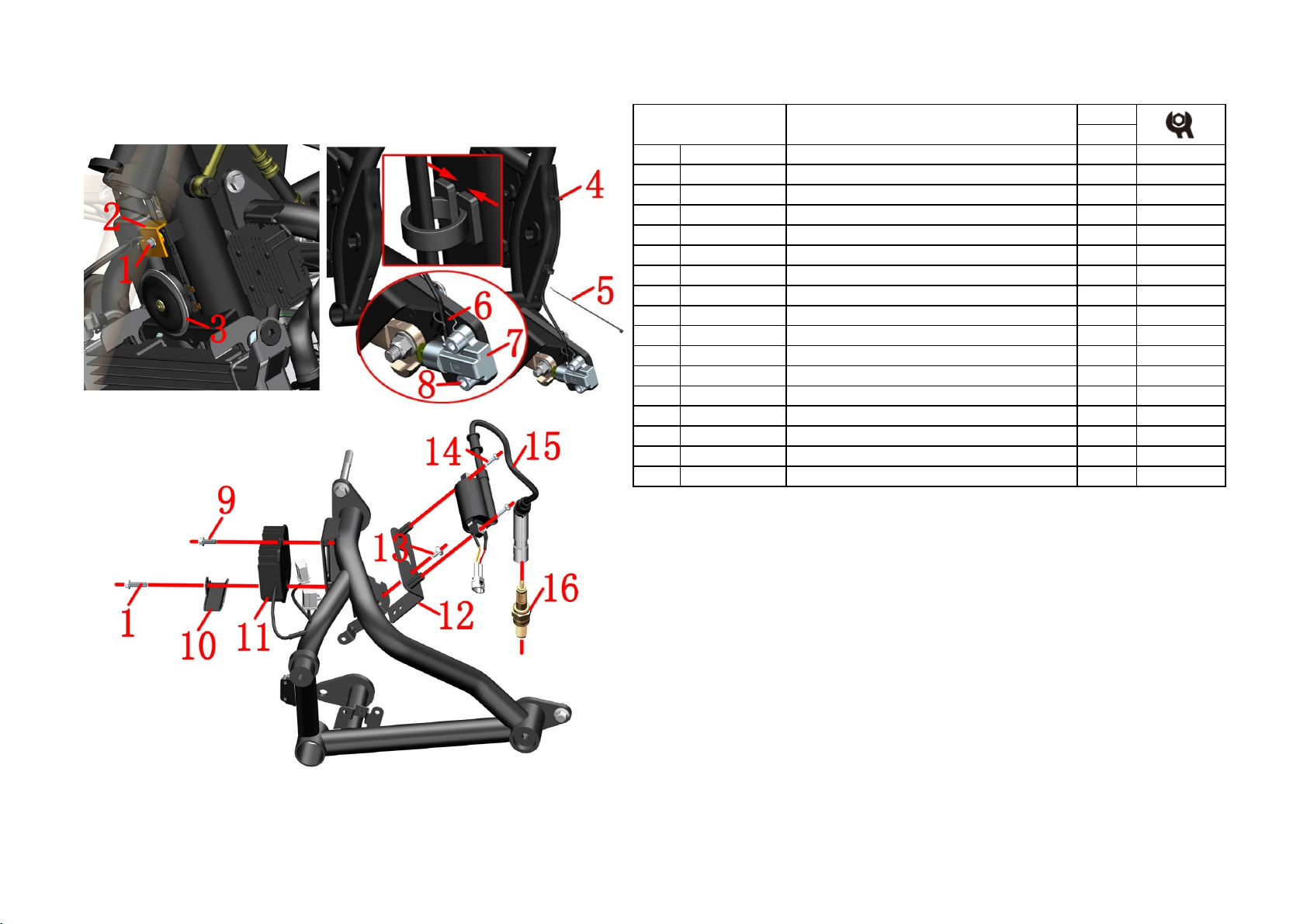

●Flasher and dump switch

Remove the rubber sleeve ⑺that connects the flasher ⑹to the mounting bracket on the frame, and remove the

dump switch with the same method, then separate the dump switch ⑸.

●Relay and ECU

Locate the main harness rubber sleeve on the right side of the frame, pull out the EFI relay ⑷. Locate the

starter relay ⑾above the air filter to remove the sheath of the harness and remove the self-contained nut to

remove the relay from the relay bracket ⒀. Using 4# inner hexagon socket disassemble the bracket ⒀after

removing the bolt ⑿。Pull out the plug of the engine controller ⒂on the left side and use a 10# sleeve to

remove the nut ⒁. Remove the 2 bolts ⑻with 4# hexagon socket and then take off the ECU bracket ⒃.

●Seat lock

Take off the plug of the seat lock , and cut off binding ⑶. Use a 4# inner hexagon to remove the front bolt ⑻,

and remove the guide block ⑼; remove the 2 rear bolts and remove the electronic cushion lock ⑽.

●Main harness

Different plug-in methods are different, please unplug all the electrical components connected to the main

thread according to the actual operation. It needs to use a word screwdriver, forceps, scissors and other tools to

assist.The binding ⑶can be picked out by using scissors.

The plug strap ⑵is a non-detachable structure and it is not recommended to cut it directly. It is difficult to

remove the broken portion of the buckle that is forcibly removed from the frame triangular reinforcing plate.