4/ 63

Table of contents

Table of contents ...................................................................................... 4

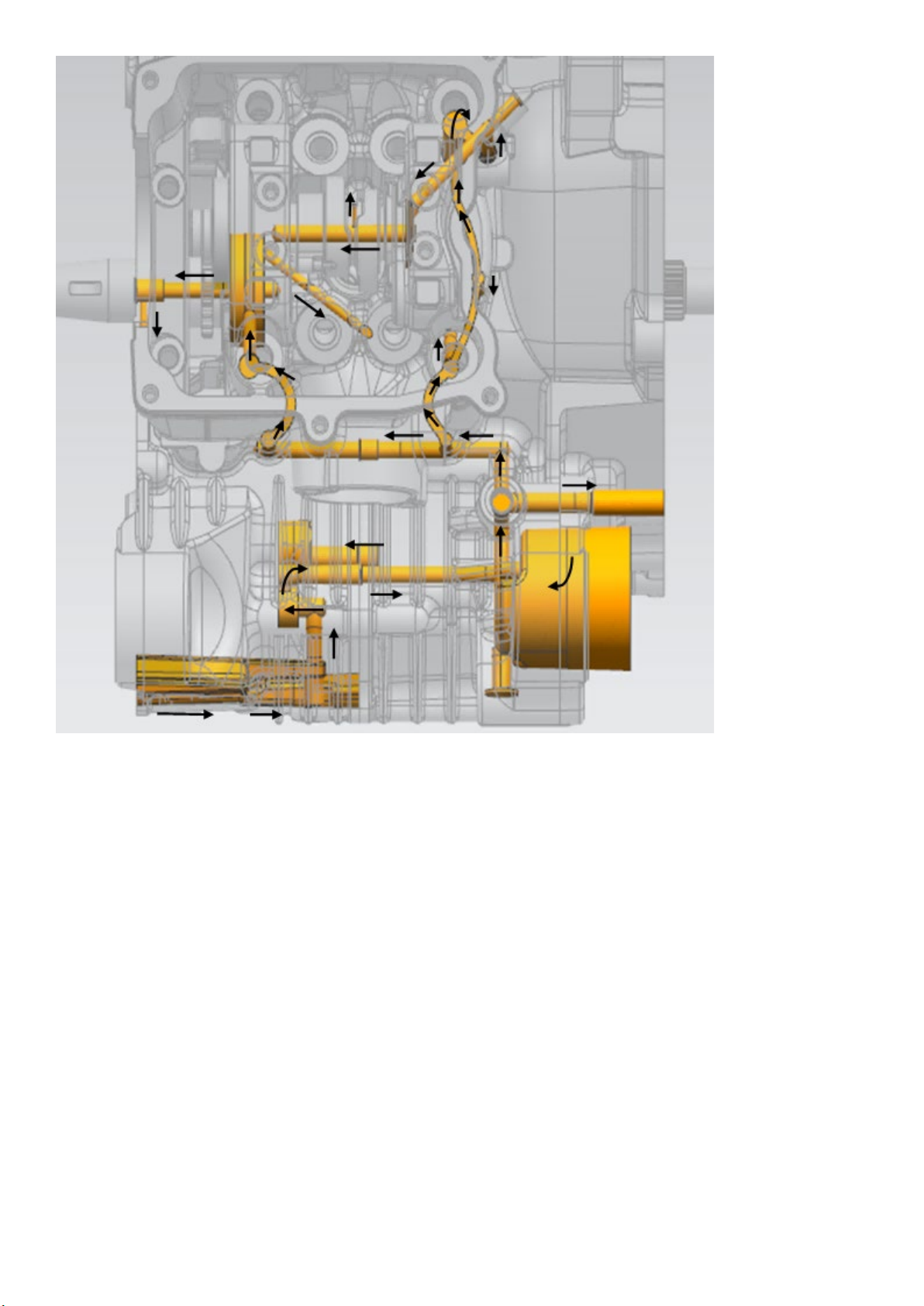

Lubrication system ..................................................................................... 6

1.Diagram of lubrication system...................................................................... 6

2. Maintenance information ......................................................................... 8

3. Common failure phenomenon/troubleshooting ....................................................... 8

4. Oil pump ....................................................................................... 9

Cylinder head cover, cylinder head ...................................................................... 11

1. System components ............................................................................ 11

2. Maintenance information ........................................................................ 13

3. Fault phenomenon/fault analysis.................................................................. 14

4. Cylinder compression test ....................................................................... 15

5. Cylinder head cover............................................................................. 15

6. Cylinder head .................................................................................. 16

7. Guide bar ..................................................................................... 24

8. Tension strip ................................................................................... 25

9. Tensioner ..................................................................................... 27

Cylinder, piston....................................................................................... 28

1. System components ............................................................................ 28

2. Maintenance information ........................................................................ 29

3. Troubleshooting ................................................................................ 29

4. Cylinder ....................................................................................... 29

5. Piston......................................................................................... 30

Left crankcase cover, continuously variable clutch sub-assembly ............................................ 33

1. System components ............................................................................ 33

2. Maintenance information ........................................................................ 35

3. Common failure phenomenon/troubleshooting ...................................................... 35

4. Left crankcase cover ............................................................................ 36

5. CVT clutch sub-assembly........................................................................ 37

Right crankcase cover, magneto ........................................................................ 40

1. System components ............................................................................ 40

2. Right crankcase cover / magneto stator............................................................ 41

3. Magneto rotor .................................................................................. 43

4. Water pump ................................................................................... 45

Gearbox............................................................................................. 49

1. System components ............................................................................ 49

2.Maintenance information ......................................................................... 50

3. Fault phenomenon/fault analysis.................................................................. 50

4. Disassembly and decomposition of the gearbox..................................................... 51

Five, gearbox gear, bearing inspection............................................................... 52

6. Gear box assembly ............................................................................. 53

Crankcase ........................................................................................... 54

1. System components ............................................................................ 54

2. Maintenance information ........................................................................ 55