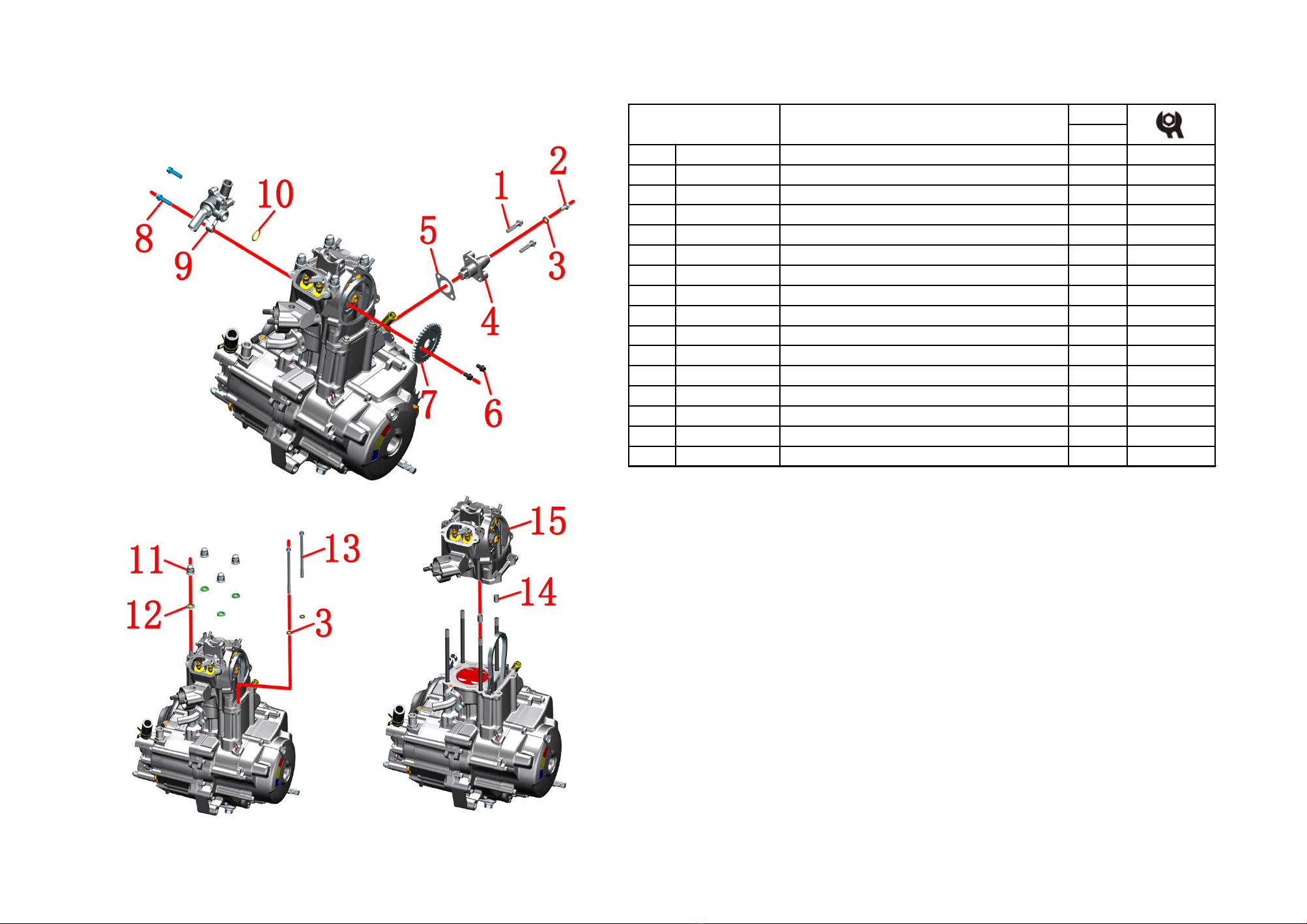

2-Cylinder head assembly

6

CHK

ADJ

NO. PART NO.

1 1251112-002093 GB16674 M6×30 Hexagon flange bolts

2 1251100-067093 M6×10 top pin bolt (color Zinc)

3 1251513-001019 6.3×12×1.6 copper gasket

4 1051270-004000 ZT1P72MN tensioner sub-assembly

5 1051253-004000 30×38 Washer, tensioner

6 1251100-340094 M6×10 Hexagon flange bolts

7 1050157-012000 ZT163ML timing driven sprocket

8 1251100-061093 M6×22 Hex flang bolt thread

9 1271200-199000 KD200-U thermostat

10 1051468-010000 16.5×1.95 EPDM

11 1251300-093000 Non-standard cap nut M8×18

12 1051661-001000 Combined gasket φ9×φ18×2 (Dacromet)

13 1251112-007093 GB16674 M6×1055 Hexagon flange bolts

14 1251401-003000 φ10×14 dowel pin

15 4050657-006000 ZT163ML cylinder head sub-assembly

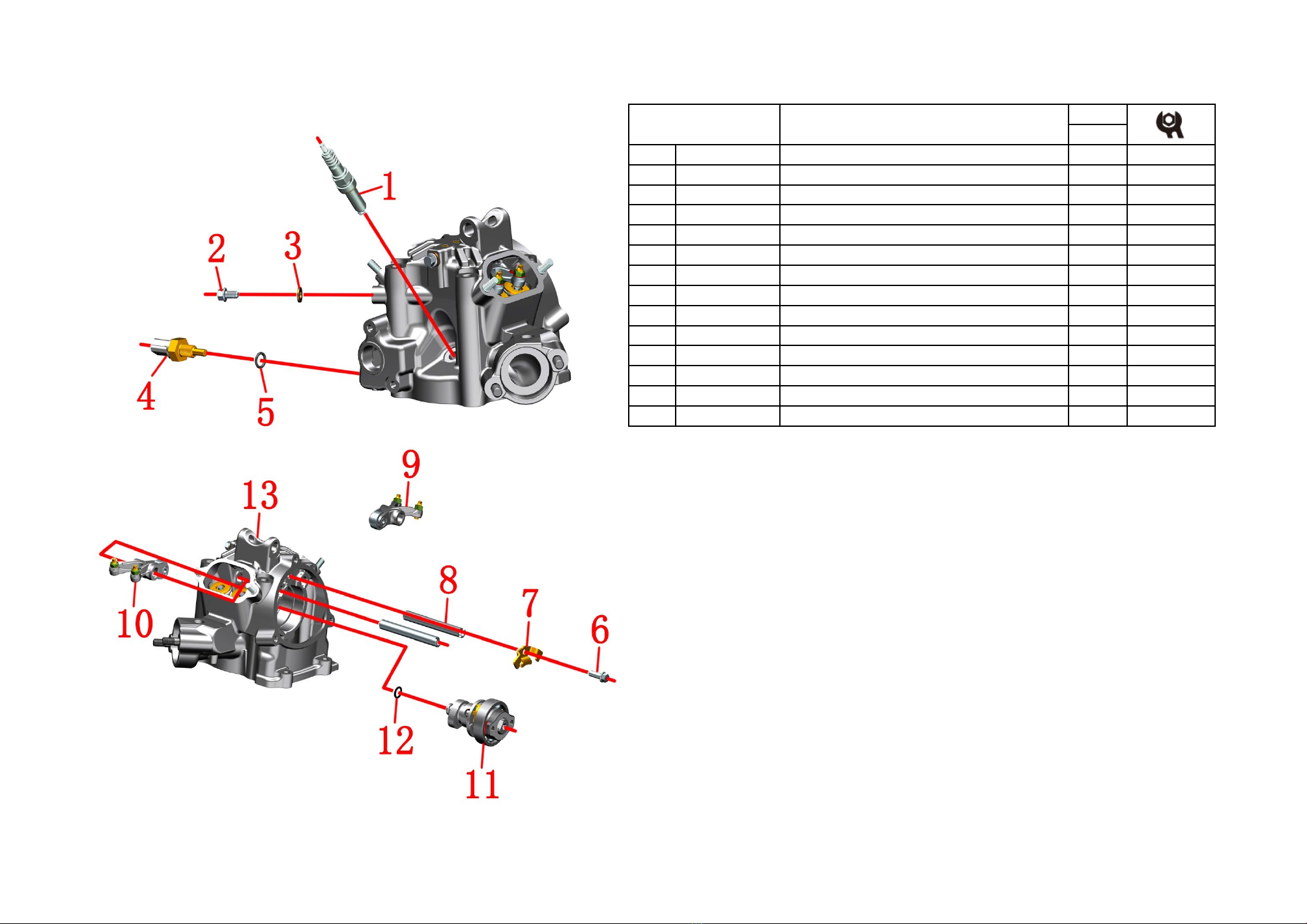

assembly Removal of cylinder head-2

●Removal of cylinder head-2

Use an 8# sleeve to pre-loosen the bolts ⑵, then remove the 2 bolts ⑴, and take out the tensioner ⑷and

gasket ⑸.

Use an 8# sleeve to remove the 2 bolts ⑹on the timing driven sprocket ⑺, and take out the timing driven

sprocket ⑺.

Use an 8# sleeve to remove 2 bolts⑻, and remove the thermostat ⑼and O-ring ⑽.

Use an 8# socket to remove 2 bolts ⒀, and take out 2 gaskets ⑶.

Use a 14# sleeve to remove 4 nuts ⑾, and take out 4 gaskets ⑿.

Grasp the cylinder head ⒂and remove it from the engine.

Note: 2 locating pins ⒁Be careful not to lose or drop them inside the engine.

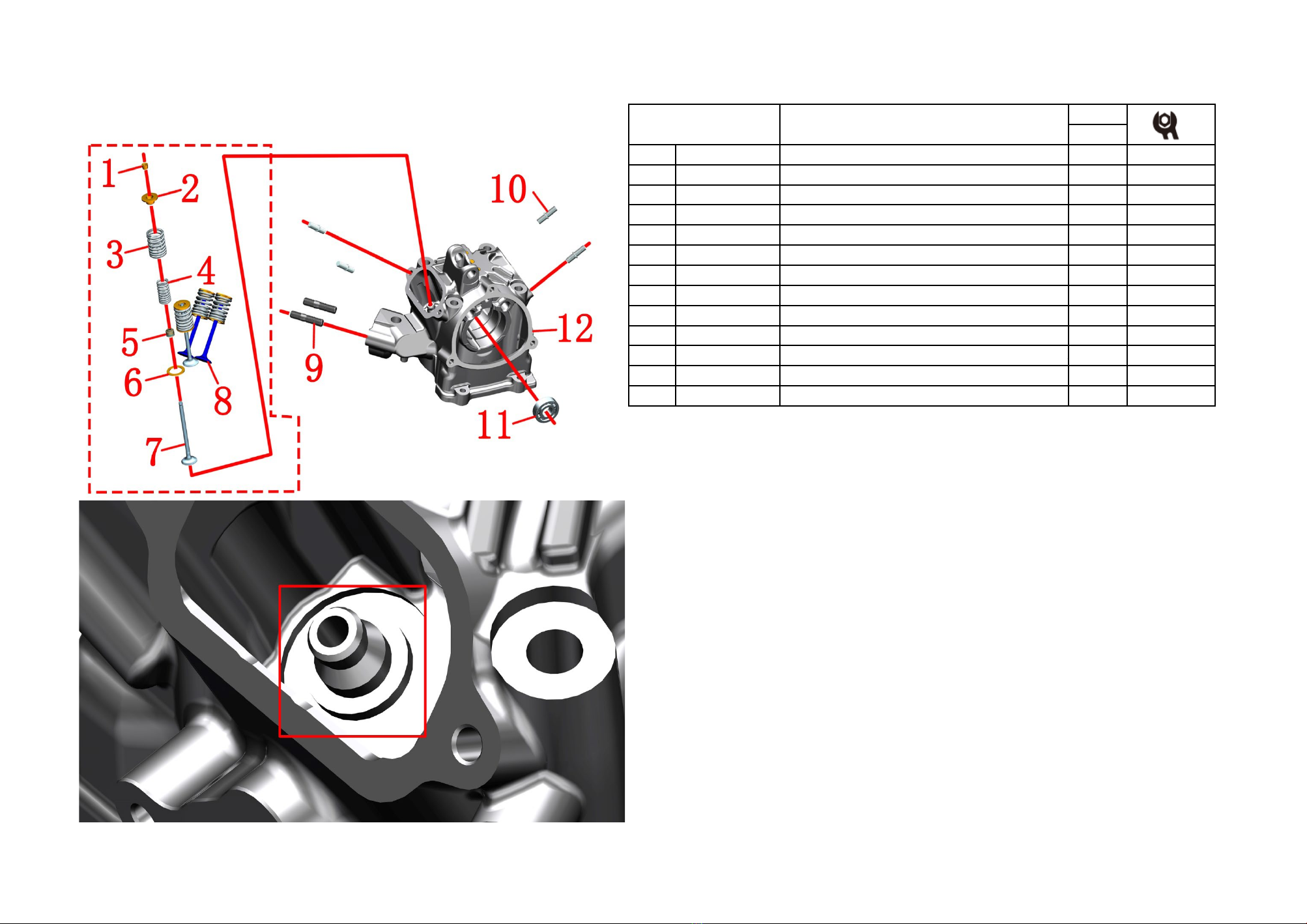

During installation, it is necessary to use an 8# sleeve to remove the bolts ⑵and gaskets ⑶on the

tensioner ⑷, and then use tooling to retract the tensioner strut and put the tensioner ⑷back.

CAUTION:

●Do not let foreign objects fall into the engine during disassembly and installation.

●When installing the bolts at the timing sprocket ⑹, apply an appropriate amount of thread fastening glue

to the threads.

●The nut ⑾needs to be tightened diagonally to the appropriate torque standard during installation.