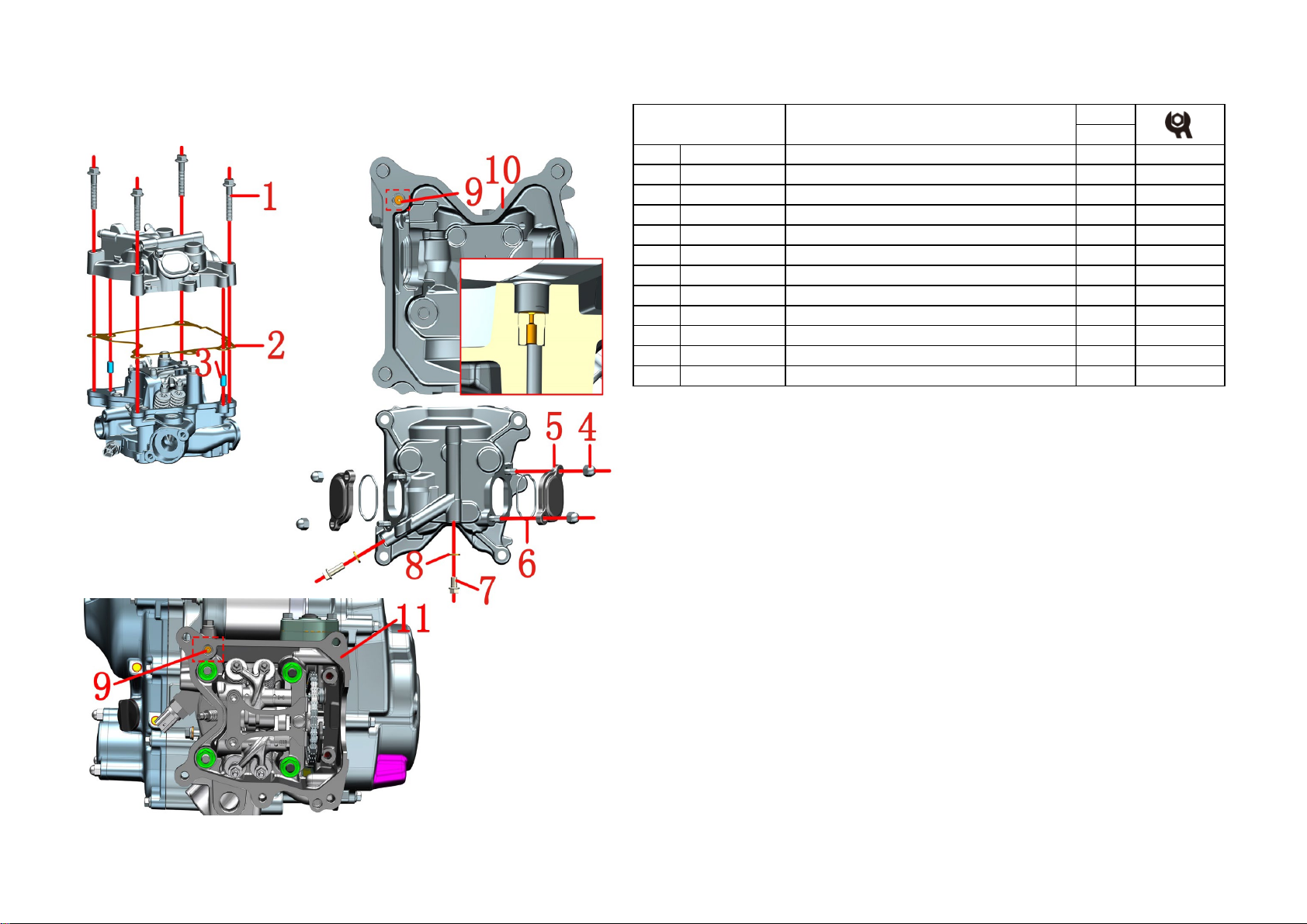

2-CYLINDER HEAD ASSEMBLY

8

CHK

ADJ

NO. PART NO. PART NAME QTY CAUTION

1 1250101-076093 GB16674 M8×45 (environmental protection color zinc) 4 25±3N.m

2 1051656-001000 ZT158MJ cylinder head cover gasket 1

3 1251401-001000 φ8×14 hollow positioning pin 2

4 1251300-056093 M6 cap type 9 grade nut (color zinc) 4 10±1.5N.m

5 4050956-002000 ZT158MJ valve cover 2

6 1051468-009000 37×1.9 Acrylic O-ring 2

7 1251100-067093 M6×10 top pin bolt (color zinc) 1 10±1.5N.m

8 1251513-001019 6.3×12×1.6 copper gasket 3

9 1051754-002000 1.2×6×7 oil pin 1

10 4050756-002000 ZT158MJ cylinder head cover 1

11 4050656-004000 ZT158MJ cylinder head 1

Fig.4 CYLINDER HEAD

ASSEMBLY Cylinder head cover assembly

PROCEDURE:

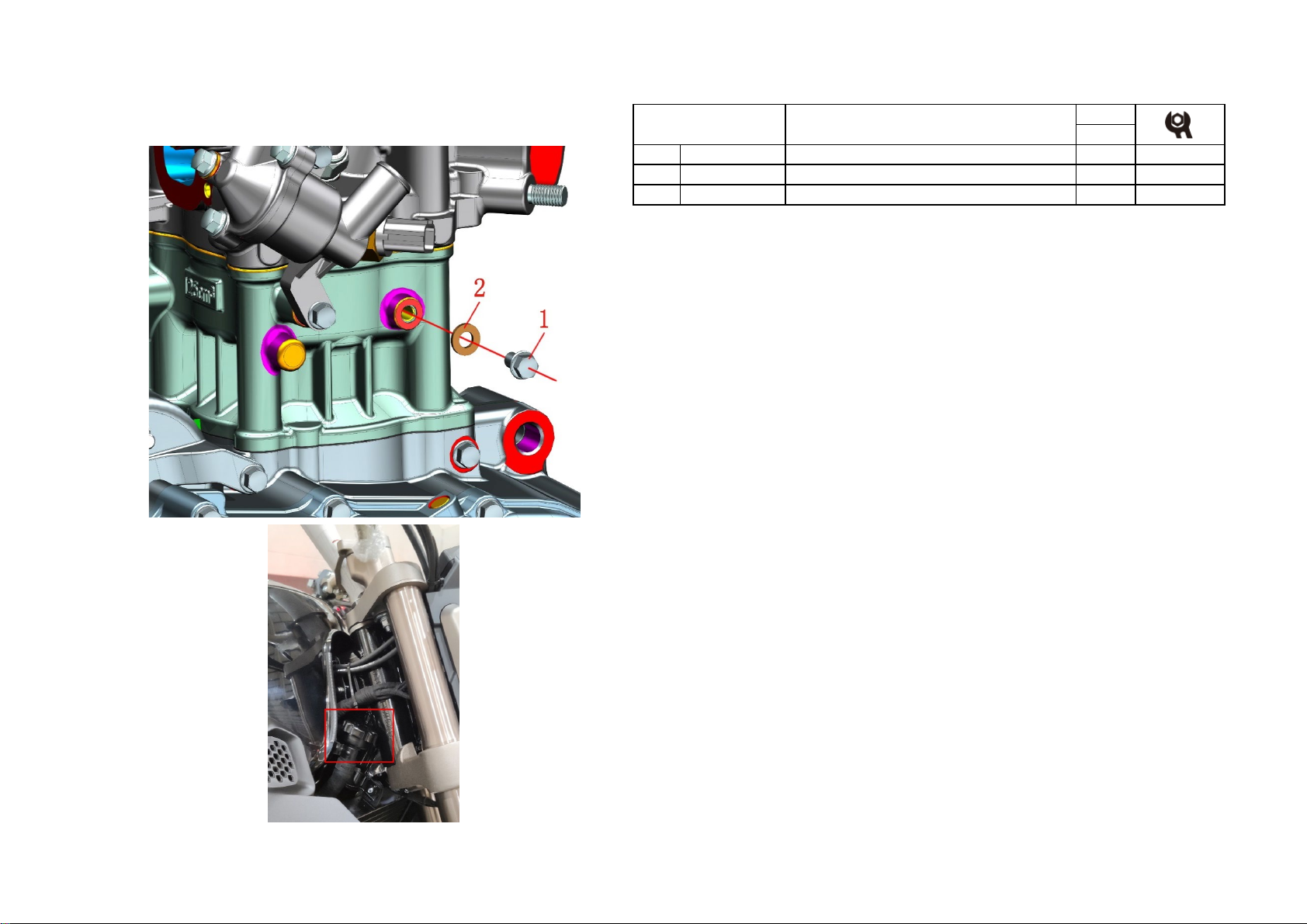

●Use the 12#T rod sleeve to remove the four bolts (1) to remove the cylinder head cover, cylinder head cover

gasket (2) and positioning pin (3).

●Clean up the remaining sealant on the joint surface, and be careful not to drop foreign matter into the engine.

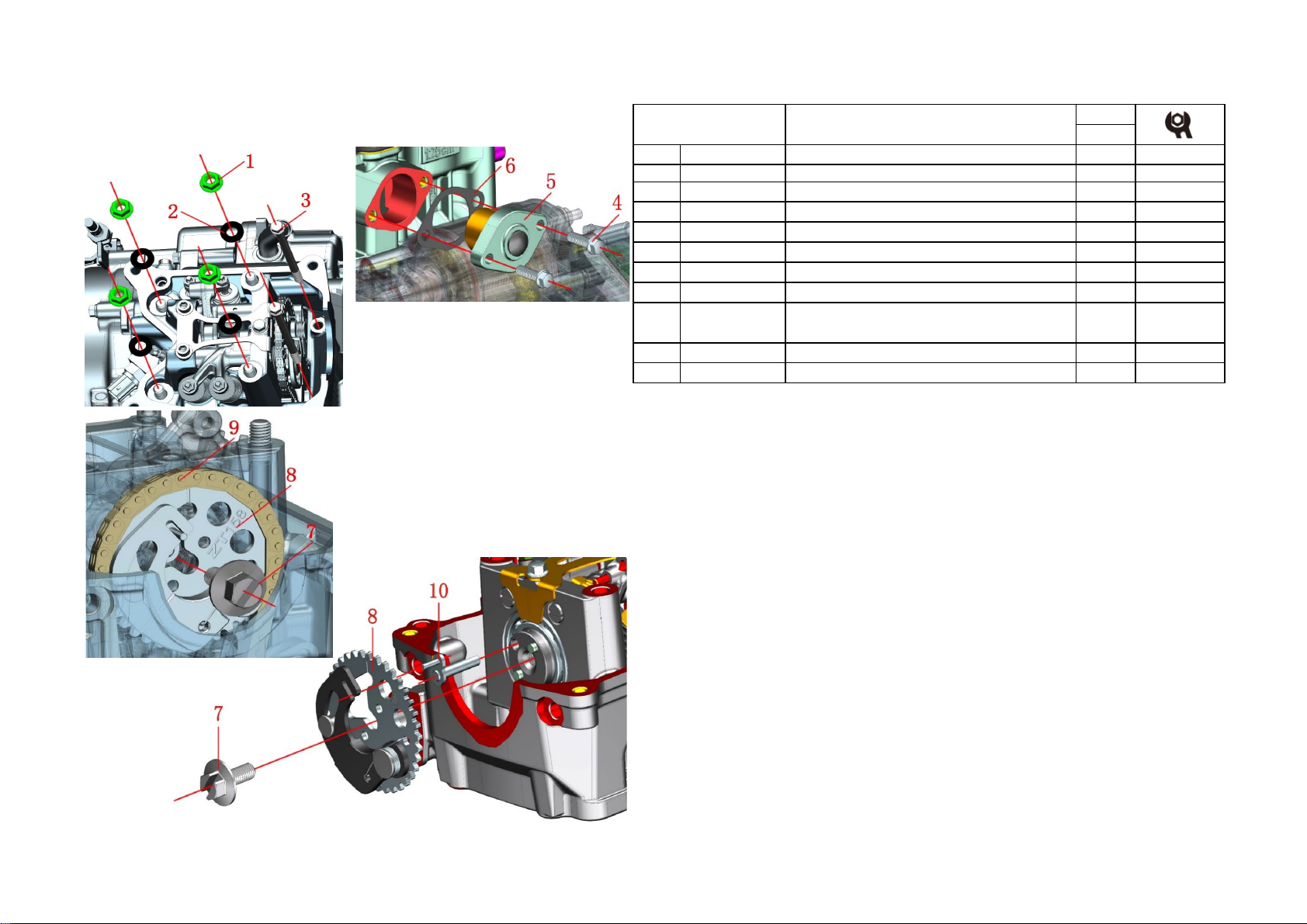

●Use a 10#T rod sleeve to disassemble the cover nut ⑷, and remove the valve chamber cover ⑸and the

sealing ring ⑹.

●Use 8#T rod sleeve to remove two bolts ⑺, and remove two washers ⑻.

CAUTION:

●The cylinder head cover gasket ⑵ is a one-time use, and must be replaced after disassembly, otherwise it

will cause a series of problems such as improper sealing and oil leakage.

●When cleaning residual sealant and other impurities, avoid foreign matter from entering the engine.

●The oil passing pin ⑼ is one of the passages of the oil circuit, which cannot be blocked, and there is an

interference fit with the cylinder head cover ⑽.Removing the oil pin may cause damage tothe joint surface.

●Both bolts ⑺ can be screwed out when the engine is running to check if there is oil leakage, as one of the

ways to check whether the oil is on the cylinder.

●Subsequent production will switch the oil passing pin ⑼on the cylinder head cover ⑽to the cylinder head

⑾.