10

3

2 4

1 5

6

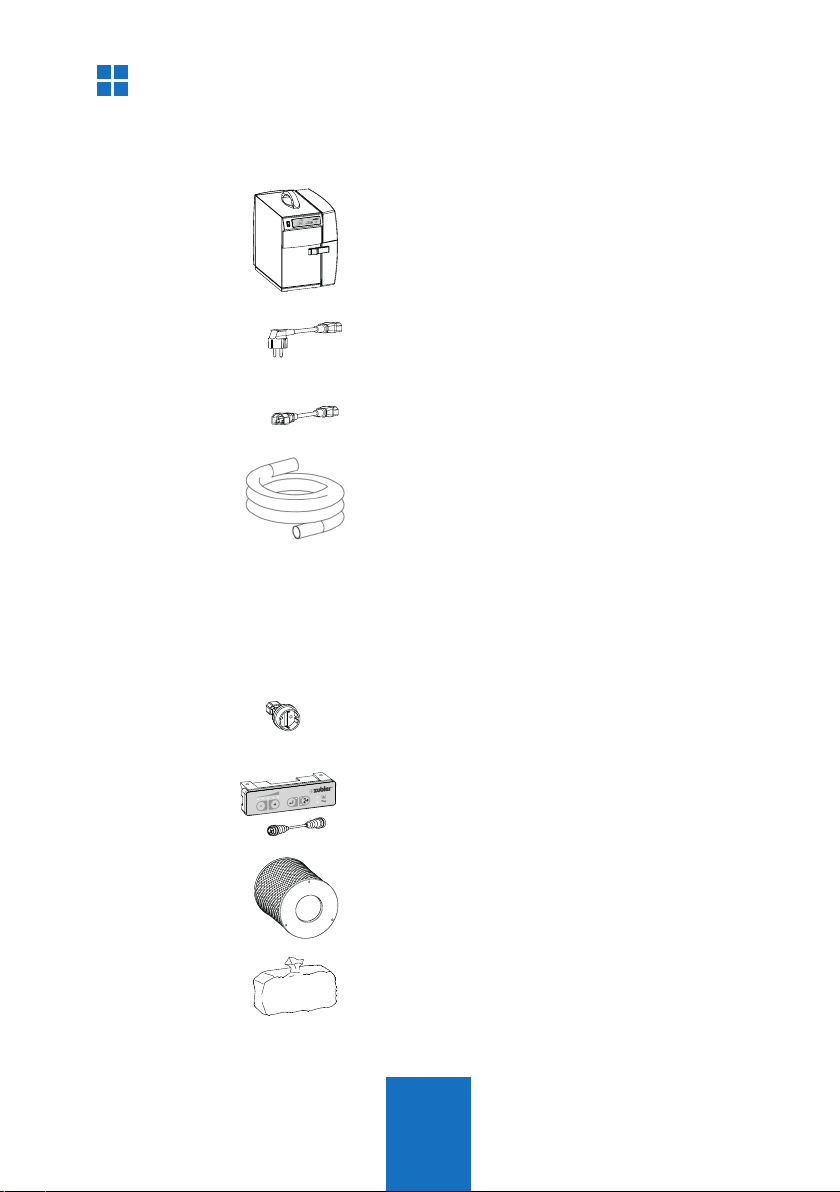

1.3.1

Appliances without interface

n

If your appliance is equipped with a IEC

plug type C14, use the enclosed IEC

power cord (C13/C14) to connect the

appliance to power socket 8.

The power cord which was enclosed

with your appliance is not needed.

n

If your appliance is equipped with a CEE

mains plug type F or C, you will need an

optional CEE-adaptor (CEE/C14) O.No.

012/00701.

The max. power rate of the appli-

ance is limited to 600W (120V)or

1200W (240V)!

1.3.2 Appliances with switching output

nIf your working appliance has a

switching output, a control cable

(special accessory) can be used to

connect to the extraction system.

Instead of C13 low temperature power

outlet 8, use the data interface 4.

nSome handpiece controls, e.g. The

Zubler K50, Kavo K-Control or Schick

Qube can also be coupled with the

suction point opener via a control

line instead of the power supply.

(Matching adapter cable on request).

1.3.3

Appliances and machines with

230V output

nIf there is a 230 V outlet on the

machine for the extraction, use

exclusively the SL230 accessory

adaptor

1.3 Connecting the working tools

Pin Cabel

assignment plan

1 grey Start 2 (IN)

2 (pink) NC

3 white

Freigabe (OUT)

4 brown GND

5 green Start (IN)

6 yellow GND

PIN assignment Connector 15