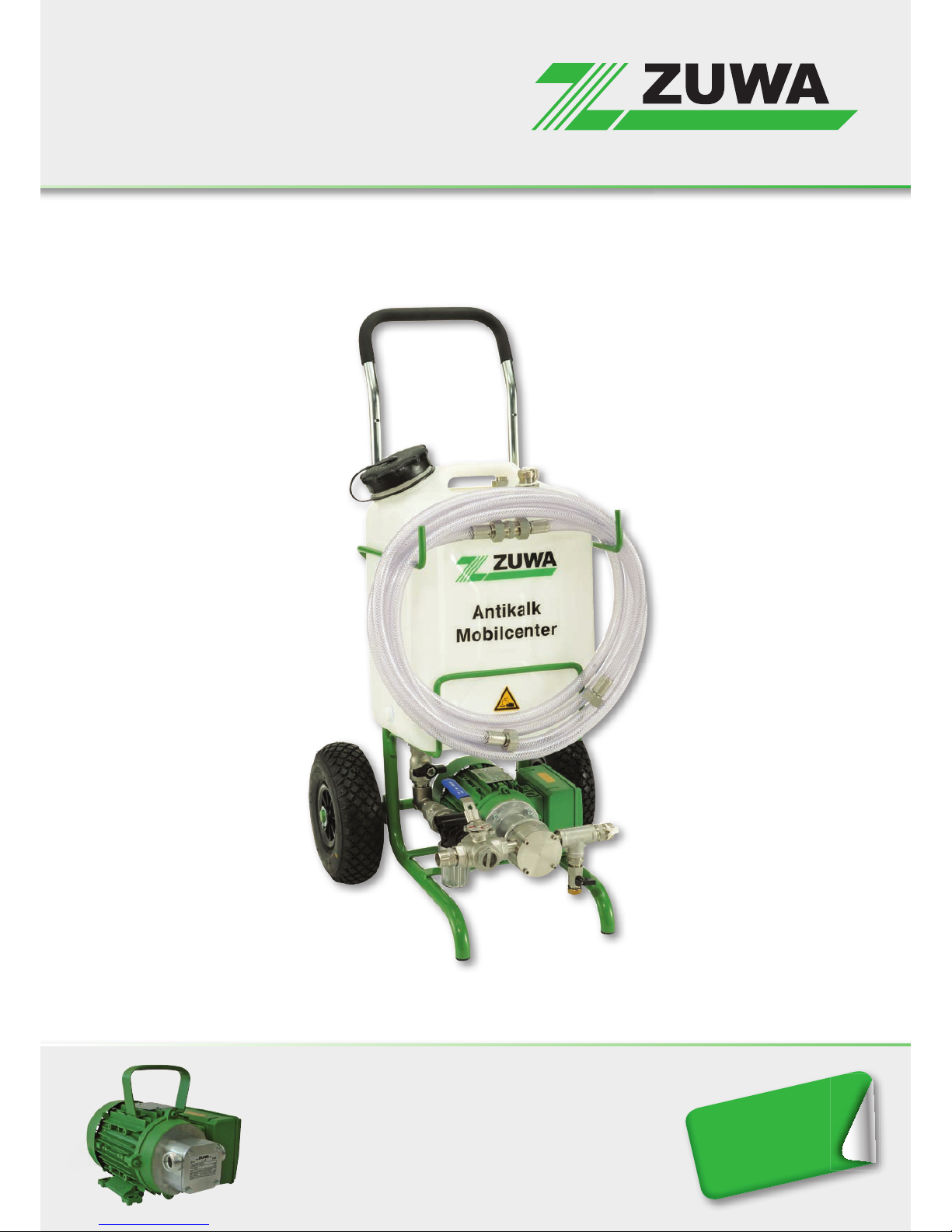

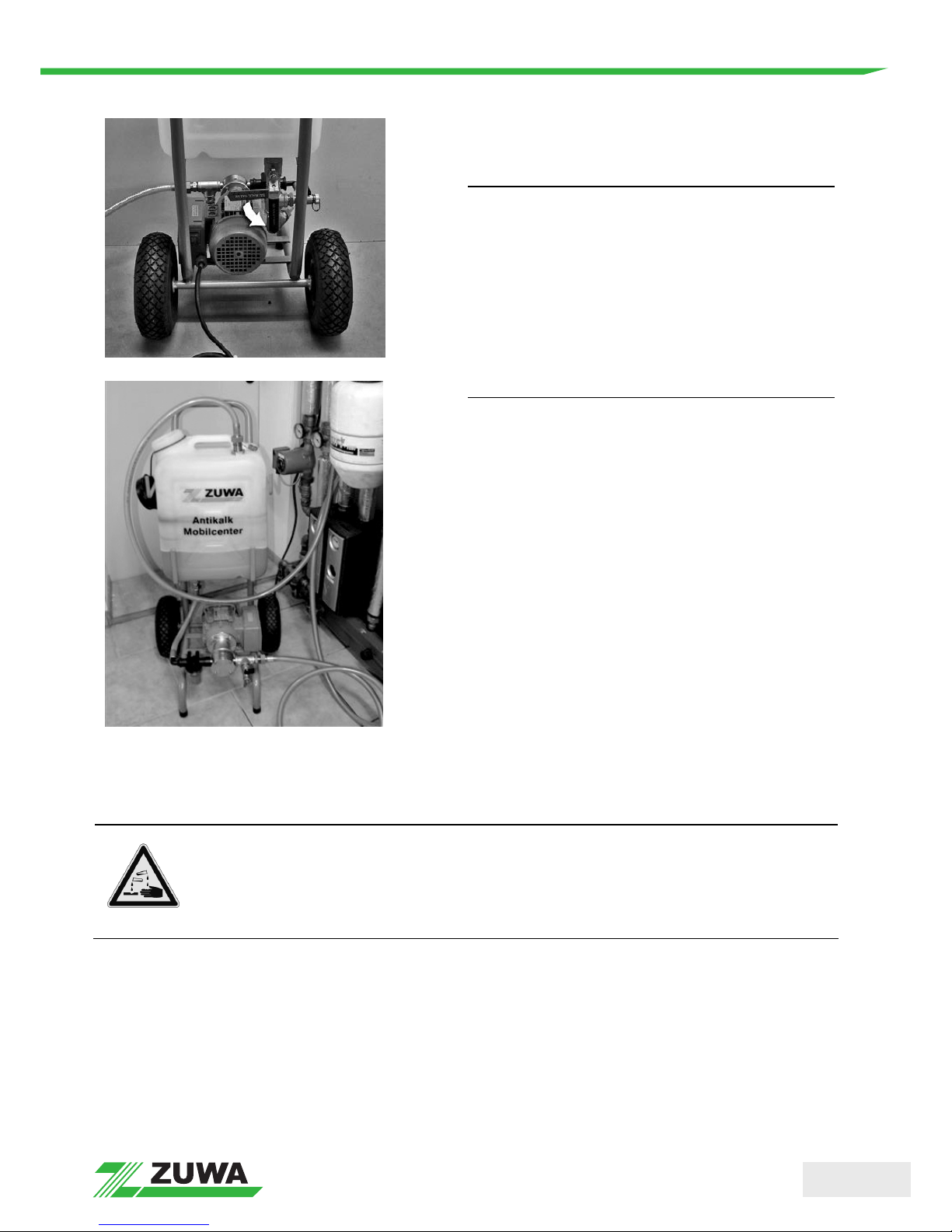

DESCAL with NIROSTAR 2000-A

Original Operating Instructions

Content

1.

Declaration of conformity ......................................................................................3

2.

Introduction ...........................................................................................................3

2.1

Further applicable documents...........................................................................3

2.2

Legend ..............................................................................................................4

3.

Safety....................................................................................................................4

3.1

General safety instructions................................................................................4

3.2

Safety instructions for potentially hazardous liquids..........................................6

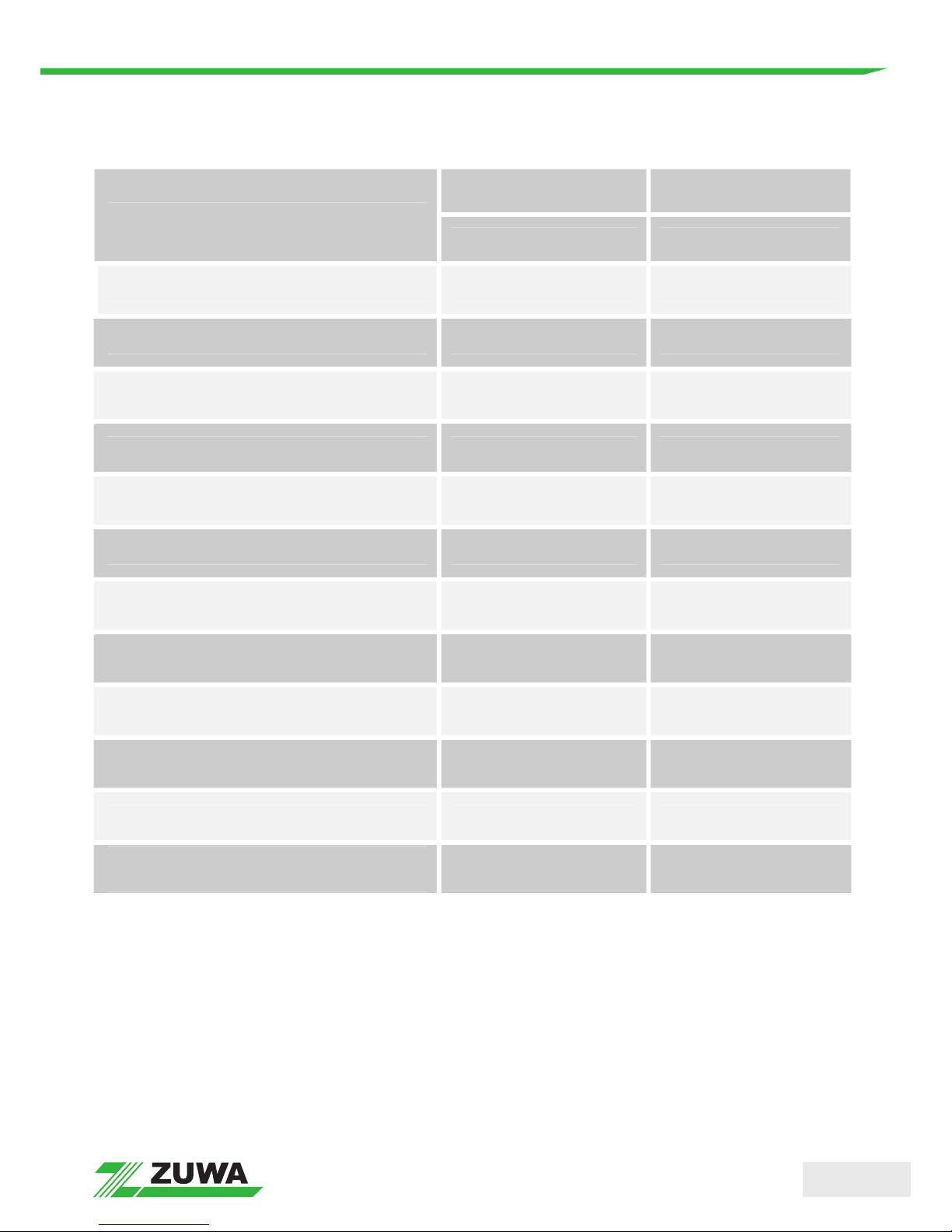

4.

Technical Data ......................................................................................................7

5.

Transportation and unpacking ..............................................................................7

6.

Mounting and commissioning ...............................................................................8

6.1

Cleaning the filter during application .................................................................9

7.

End of operation..................................................................................................10

8.

Warehousing.......................................................................................................11

9.

Maintenance .......................................................................................................11

9.1

Connections ....................................................................................................11

9.2

Cleaning the filter ............................................................................................11

9.3

Disassembling the pump .................................................................................11

9.4

Replacing components....................................................................................12

9.5

Assembling the pump......................................................................................12

10.

Troubleshooting ..................................................................................................13

11.

Accessories ........................................................................................................14