© 2mag AG Page 4 of 44 Version: 5.1

Contents

A Quick start ______________________________________________ 5

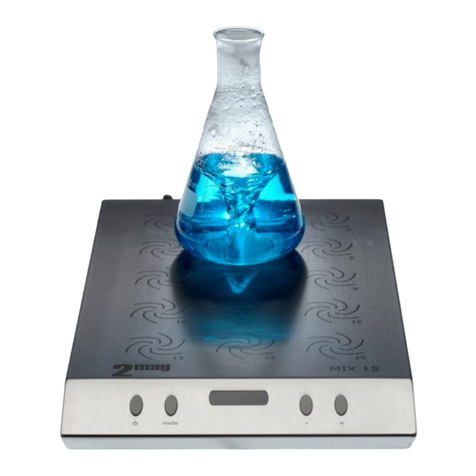

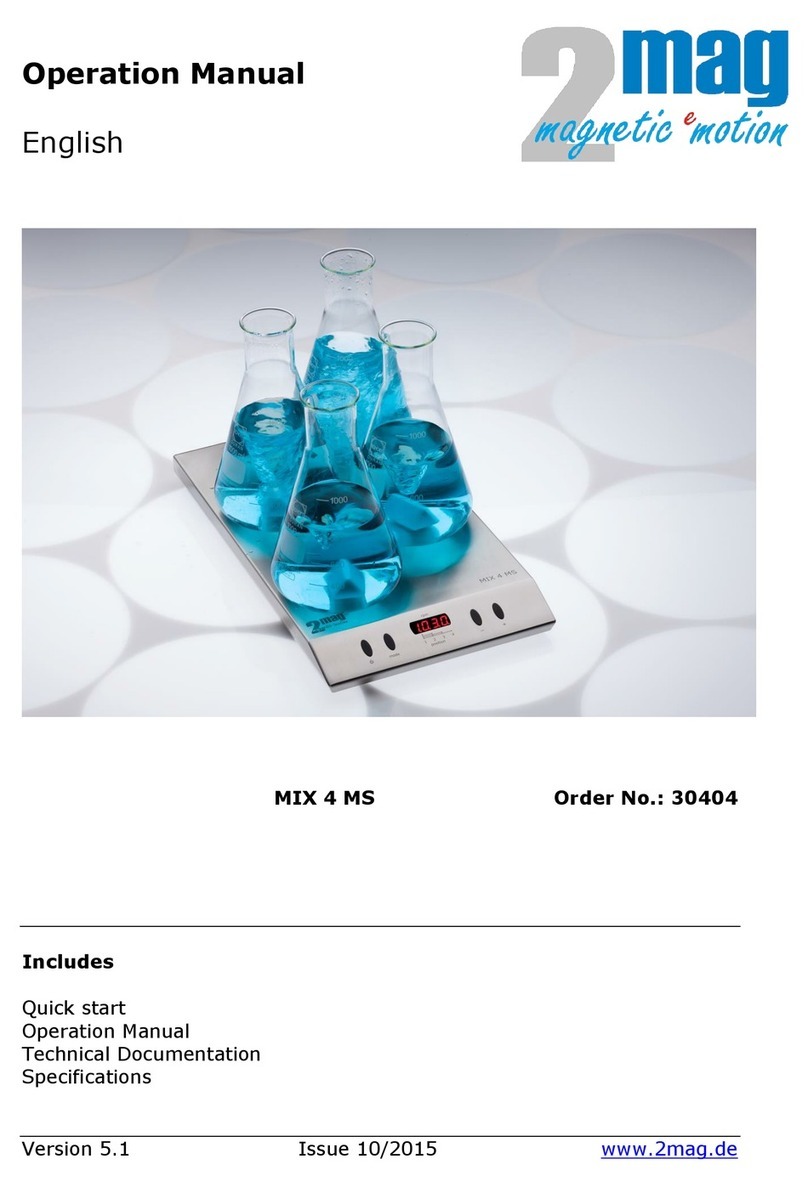

1. Overview of your product _______________________________________ 5

2. Applications __________________________________________________ 6

2.1 Operator __________________________________________________ 6

2.2 Basic functions _____________________________________________ 6

2.3 Product combinations________________________________________ 6

2.4 Application not for the intended use ____________________________ 6

2.5 Combinations of vessels______________________________________ 7

2.6 Stirring bars _______________________________________________ 8

2.6.1 ASTEROID Stirring Bars ____________________________________ 8

2.7 Tips and hints to the topic stirring ______________________________ 9

3. Installation__________________________________________________ 10

3.1 Safety advice _____________________________________________ 10

3.2 Installation, connection to the control unit MIXcontrol eco __________ 11

3.3 Installation, connection to the control unit MIXcontrol 20___________ 13

3.4 Installation, connection to the control unit MIXcontrol 40___________ 14

4. Operating of the control units ___________________________________ 15

4.1. Operating of the control unit MIXcontrol eco ______________________ 15

4.1.1 Description functional elements MIXcontrol eco _________________ 15

4.1.2 Stirring operation and stirrer control MIXcontrol eco _____________ 16

4.2. Operating of the control unit MIXcontrol 20/40 ____________________ 17

4.2.1 Description operating elements MIXcontrol 20/40 _______________ 17

4.2.2 Stirring operation and stirrer control MIXcontrol 20/40 ___________ 18

4.3 Interface (analog) –0-10 Volts _________________________________ 20

4.3.1 Technical data ___________________________________________ 20

4.3.2 Pin-assignment, SUB-D connector ___________________________ 21

4.3.3. PIN-assignment –MIXcontrol eco –housing for cap rails _________ 22

4.3.3. Connections/PIN-assignment –MIXcontrol 20/40 DINrail __________ 23

4.4 PC-Interface –RS232 ________________________________________ 24

4.4.1 RS232 Commands________________________________________ 24

4.4.2 Format –Command –Feedback _____________________________ 25

4.4.3 Hints to Parameter Operation _______________________________ 25

4.3.4 Control of more than one units______________________________ 26

4.4.5 Control with HyperTerminal ________________________________ 27

4.4.6. Screenshots –Preferences HyperTerminal ____________________ 28

4.5 Combinations Stirring Drives –Control Units ______________________ 30

4.6 Accessory –Distributor distriBOX 4 / distriBOX 8 ___________________ 31

4.7 Accessory –Extension Cord for MIXdrive _________________________ 31

5. External heating operation in incubators and water baths _____________ 32

5.1 Accessory –Stainless Steel Bath mixBATH ______________________ 32

6. Maximum operation temperatures _______________________________ 33

B Maintenance, Cleaning and Care ____________________________ 34

C Service case and customer service___________________________ 35

D Errors _________________________________________________ 36

E Technical details _________________________________________ 37