Version 2022.4A

Contents

ZYYX - User Manual

1

Table of Contents

........................................................................................... 21. Getting Started

............................................................................................................ 21.1 Specifications

............................................................................................................ 31.2 Unpacking Your Printer

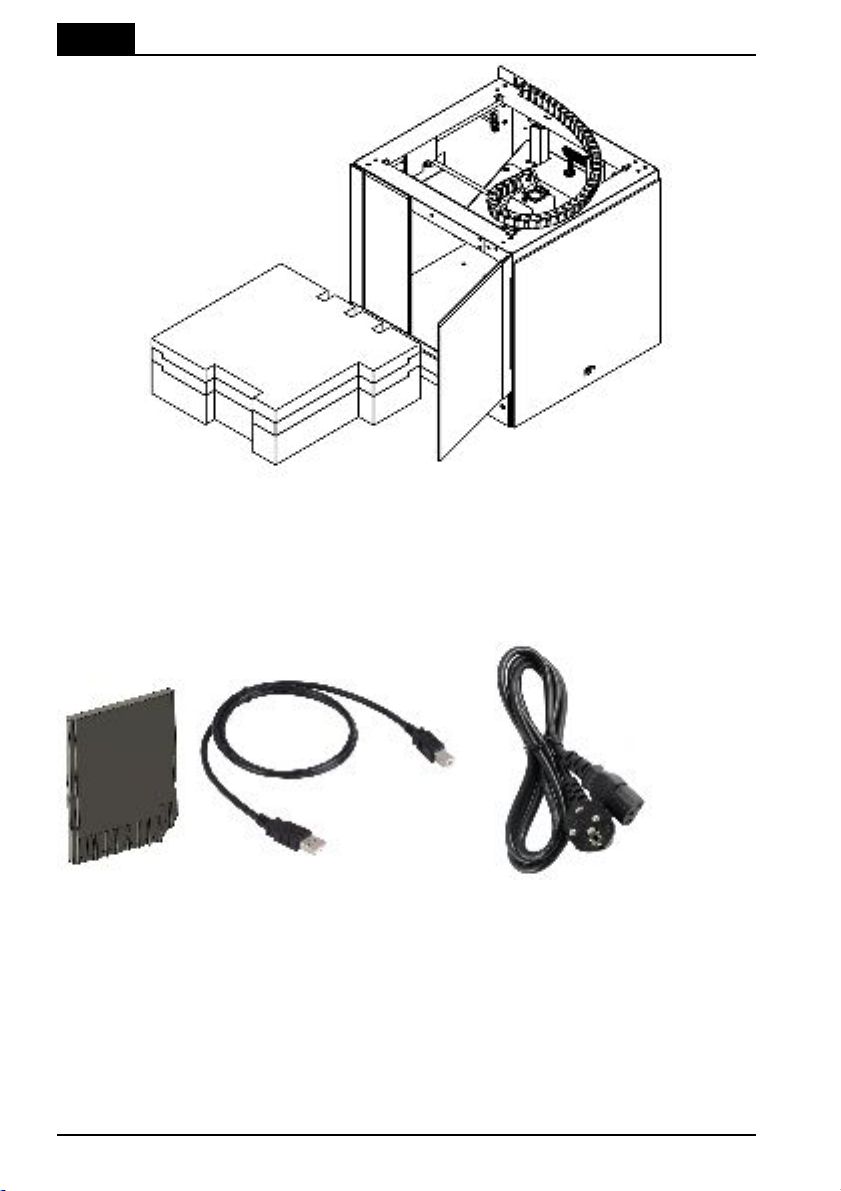

............................................................................................................ 41.3 What Is Included?

............................................................................................................ 61.4 Before Starting the ZYYX Pro II for the First Time

........................................................................................... 62. Product Overview

............................................................................................................ 82.1 User Interface

..................................................................................................................82.1.1 Keyboard Operation

............................................................................................................ 82.2 Setting Up the ZYYX Pro II Printer

............................................................................................................ 102.3 Setting Up the Simplify3D Slicer Software and ZYYX Pro II Profiles

............................................................................................................ 112.4 Slicing a First Print File

............................................................................................................ 132.5 Printing

............................................................................................................ 142.6 SwiftTool24s

............................................................................................................ 152.7 Swapping SwiftTools

............................................................................................................ 162.8 Filament Handling

............................................................................................................ 172.9 Tips and Tricks

..................................................................................................................182.9.1 Maintenance

..........................................................................................................182.9.1.1 Build-Plates

..........................................................................................................182.9.1.2 Air Filter Cartridge Ultra

..........................................................................................................192.9.1.3 Monthly Cleaning Routine

..........................................................................................................192.9.1.4 Adjusting Z-Axis Offset

........................................................................................... 193. Troubleshooting

........................................................................................... 204. Warranty

........................................................................................... 215. Standards and Compliances

............................................................................................................ 225.1 Manufacturer Declaration of Conformity

............................................................................................................ 235.2 Filament Safety Data Sheet (SDS)

................................................................................................... 24Index