6

Inspection:

1. Make sure unit is straight and operates smoothly.

2. Make sure the label is affixed to unit.

3. Make sure trigger stop is not bent or damaged.

4. Make sure cables are not kinked, frayed or damaged.

5. Make sure metal components are not damaged.

6. Make sure metal spoons and conical end fitting operate smoothly

and no metal burrs have occurred.

7. When reusing a previously drilled hole, always inspect the

hole carefully.

Storage and Cleaning:

1. Blow off unit after each use with compressed air.

2. Store in clean dry environment.

3. Store in secure locked area.

4. Store and put away at the end of each day’s work.

5. Do not pile any objects on top of unit during storage.

6. Keep unit free of grease, oils and dirt.

7. Avoid lending your unit to other workers.

Disposal:

1. Dispose of unit after any fall has occurred.

2. Dispose of unit if cable becomes kinked or bent.

3. Dispose of unit if trigger stop is bent or damaged.

4. Dispose of unit if trigger action is rough or sticky.

5. Dispose of unit if return wire becomes bent or frayed.

6. Proper disposal requires the unit’s spoons be cut off the

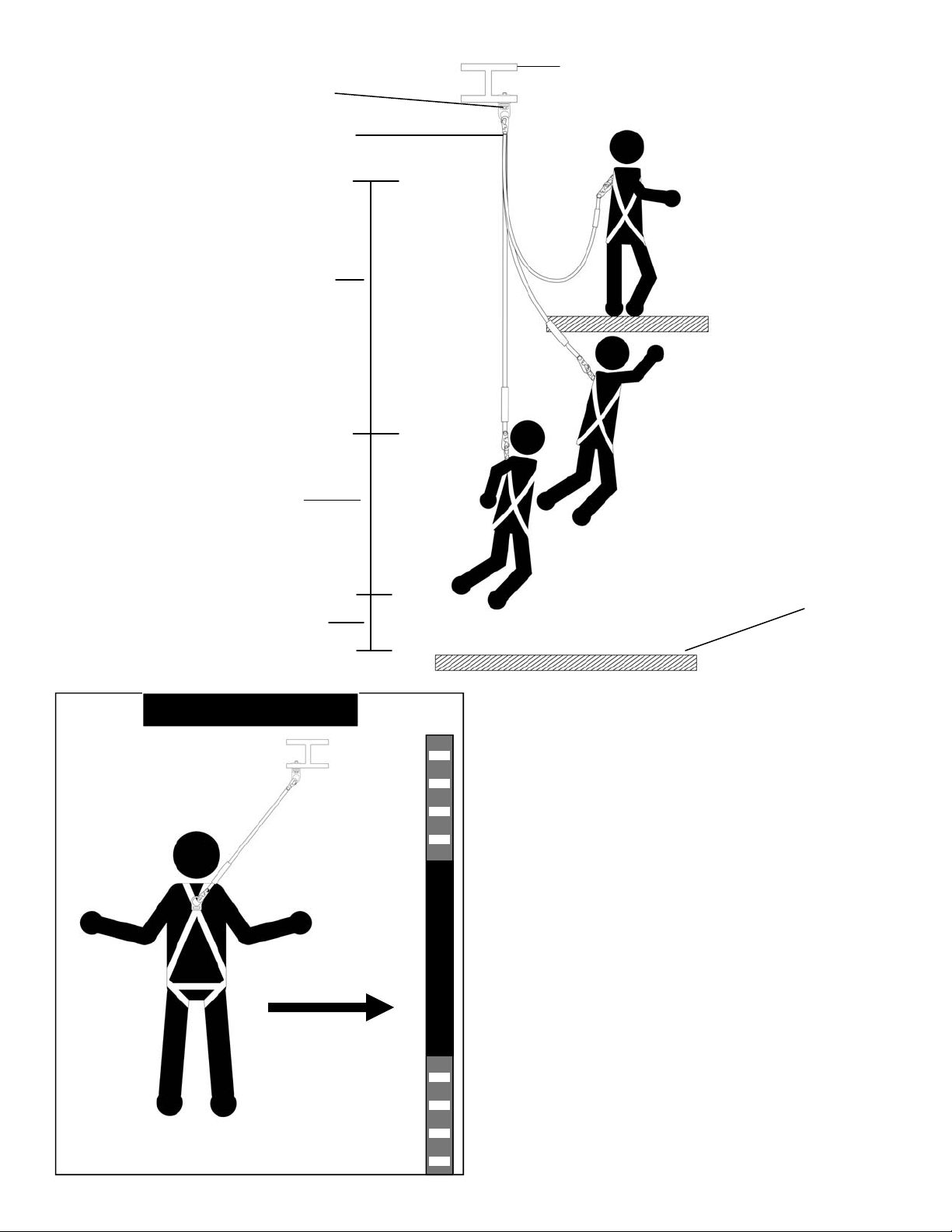

When installing the SafeClaw, place your thumb inside the anchor loop

and your first two fingers around the trigger. Retract the trigger until

the spring bottoms out. With your other hand, pinch the two spoons

between your thumb and index finger. Hold the trigger fully retracted

while inserting the unit into bottom of the hole.

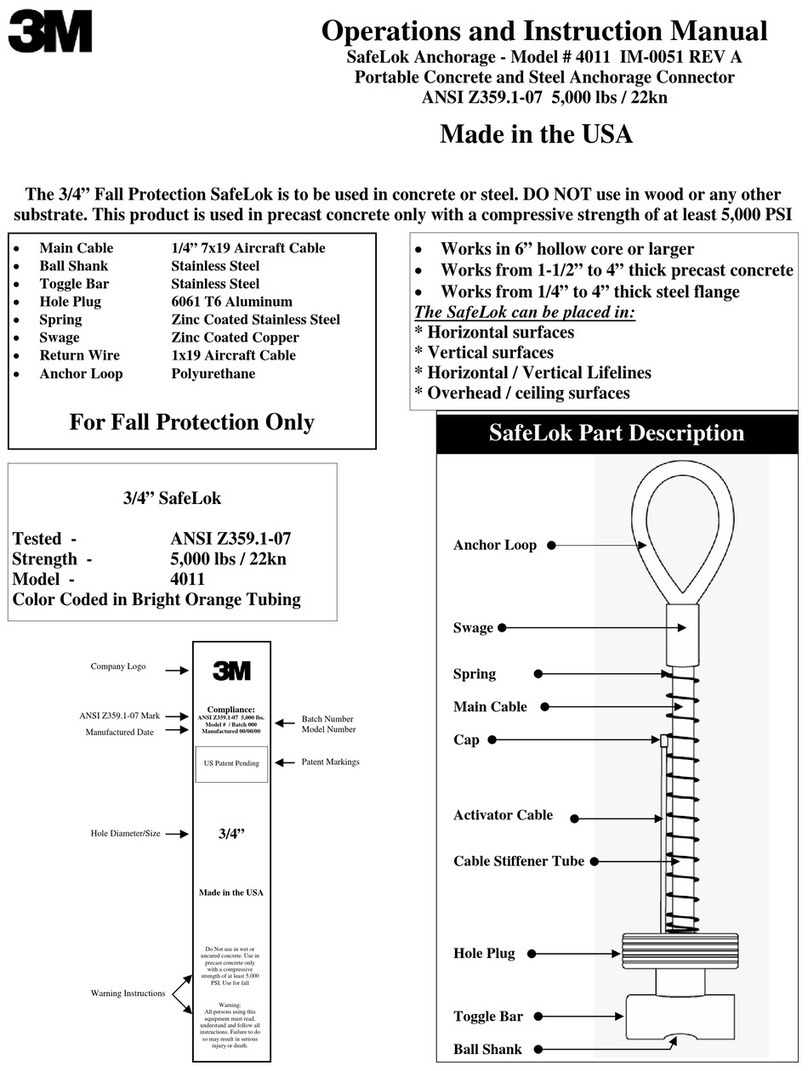

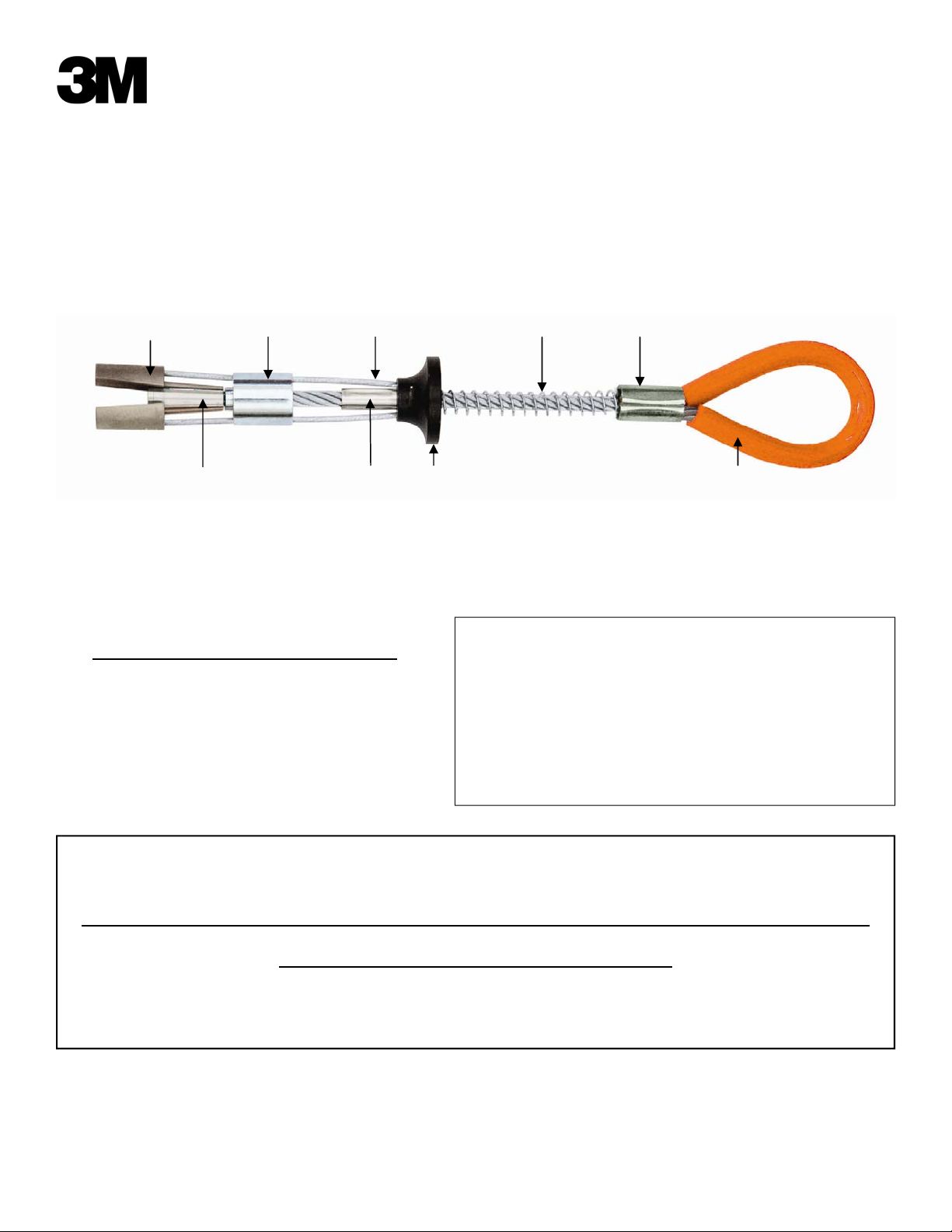

Company Logo

Hole Diameter/Size

Manufactured Date

Batch Number

Model Number

ANSI Z359.1 Mark

Warning Instructions

Compliance:

ANSI Z359.1-07 5,000 lbs.

OSHA

1910.66 & 1926.502

Model # 4075 / Batch 000

Manufactured 00/00/00

US Patent 6,729,821

US Patent 7,011,281

US Patent 7,357,363

3/4”

Warning:

All persons using this

equipment must read,

understand and follow all

instructions. Failure to do

so may result in serious

injury or death.

WARNING DO NOT use in

wet or uncured concrete.

Use in normal weight

concrete with a compression

strength at least 3,000 PSI

(20.7 MPa) Use for Fall

Protection Only

Patent Markings

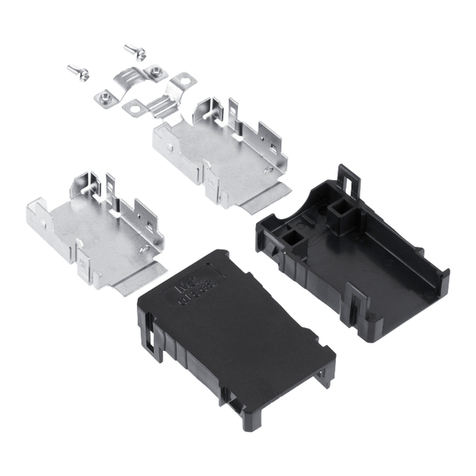

Main Cable 7x19 Aircraft Cable

End Termination 304 Stainless Steel

Spoons 304 Stainless Steel

Bushing Guide 304 Stainless Steel

Stop sleeve 304 Stainless Steel

Trigger 6061 T-6 Aluminum

Spring Zinc Coated Spring Steel

Swage Zinc Coated Copper

Return Wire 1x19 Aircraft Cable

Plastics Polyurethane

If a SafeClaw becomes stuck, insert a punch, screwdriver

or pointed object into the hole until the tip rests on the

striker plate Give a LIGHT, blunt tap with a hammer or

suitable object. The Striker Plate will be easily visible at

the edge of the hole.

SafeClaw Anchor inserted

into a 3” hole

The metal Stop Sleeve

must be inserted half

way into the hole.

1-800-560-1094

SafeClaw

Reference #

70071532330