Industrial Loadbreak Bushing Insert

200 A

15 kV Class

5810-BI-15

Data Sheet

1.0 Product Description

1.1 General

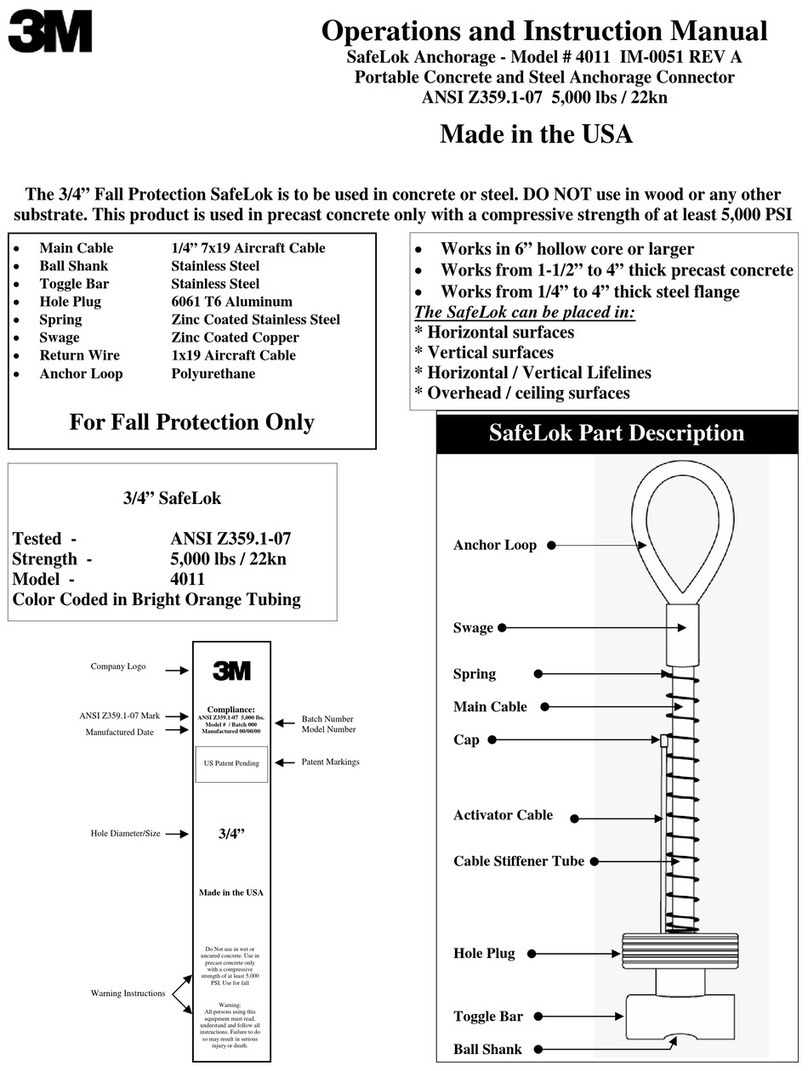

The 3M™Industrial Loadbreak 15 kV Bushing Insert

threads into a universal bushing well to provide the same

function as an integral loadbreak bushing. Using bushing

inserts makes field installation and replacement possible

and efficient. Bushing inserts and elbow connectors

comprise the essential components of all loadbreak

connections.

The Bushing Insert uses a patented “ALL COPPER

CURRENT PATH,” containing only one current transfer

point, within the insert itself. The uncomplicated nature

of the current path design delivers superior, reliable

performance.

An internal hex broach allows for positive torque controlled

installation. Using a torque tool, the bushing insert can be

properly tightened into the bushing well without the fear of

accidentally breaking the bushing well stud.

The exclusive latch indicator ring, located on the

circumference of the bushing’s collar, eliminates the

guesswork of loadbreak elbow installation on the bushing

insert. The bright yellow ring provides immediate

feedback to determine if the elbow is properly installed on

the insert. If the yellow ring is completely covered by the

loadbreak elbow, it is fully “latched.” If the ring is visible,

the elbow can be installed correctly before any problems

can occur.

The bushing insert meets all the requirements of ANSI/IEEE

Standard 386 and is completely interchangeable with mating

products that also meet ANSI/IEEE Standard 386. When

mated with a comparably rated component, the bushing

insert provides a fully shielded and submersible connection

for loadbreak operation.

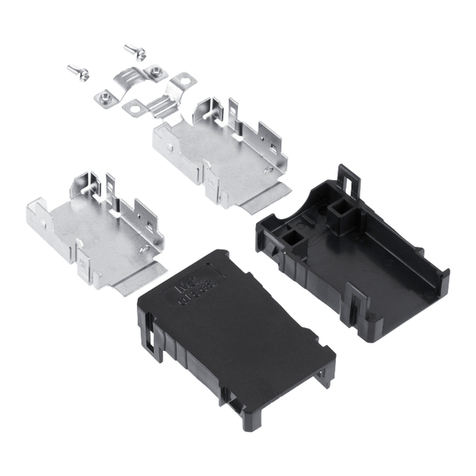

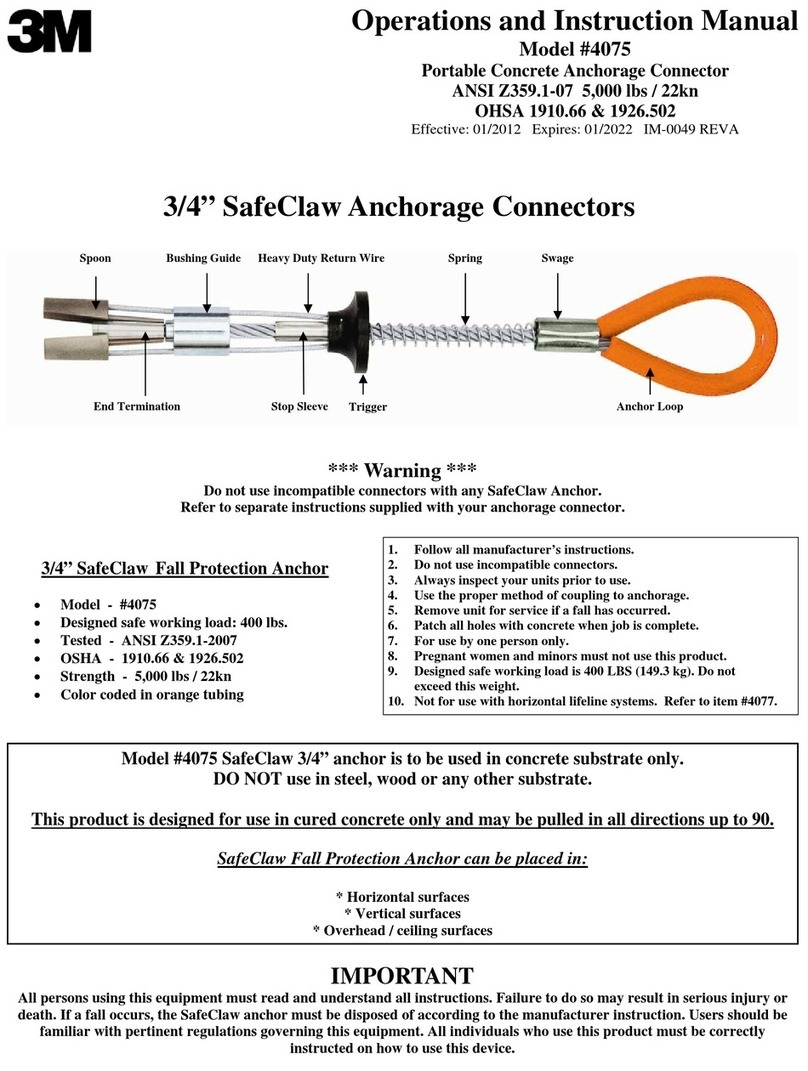

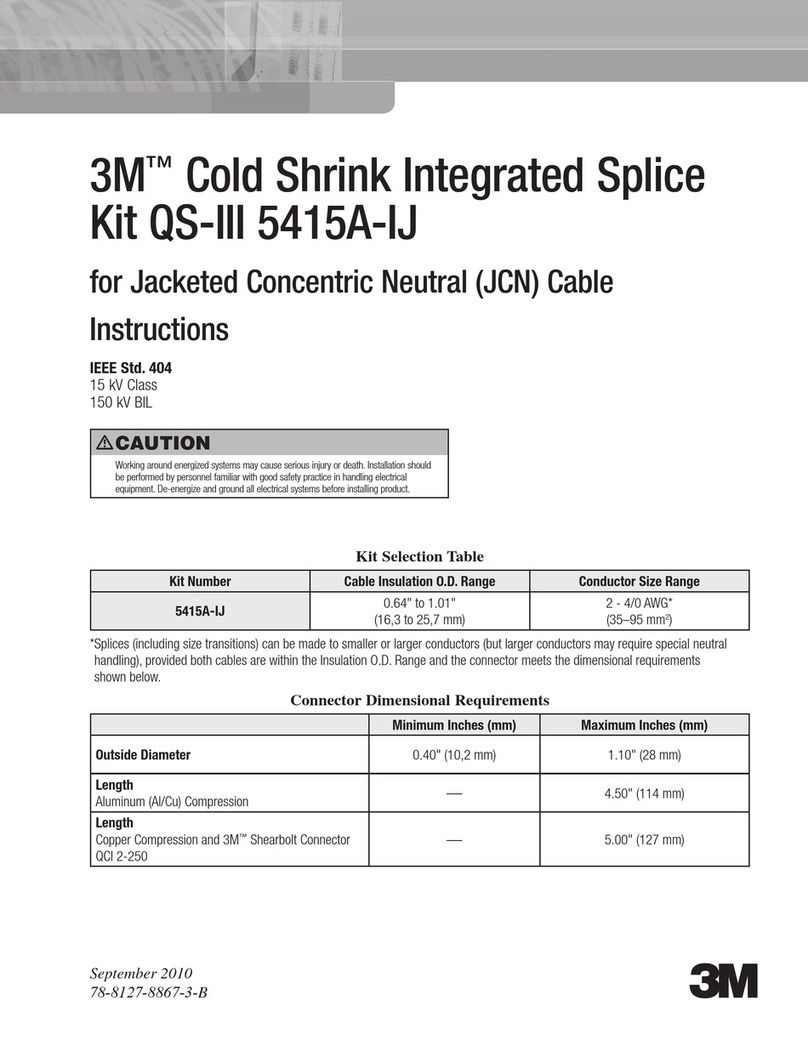

1.2 Installation

No special tools are necessary.

The insert can be installed by hand or with the assistance

of a torque tool. Using the hex-broached base (see Figure

2) and a torque tool, consistent installation can be easily

achieved. Refer to Installation Instruction Sheet for details.

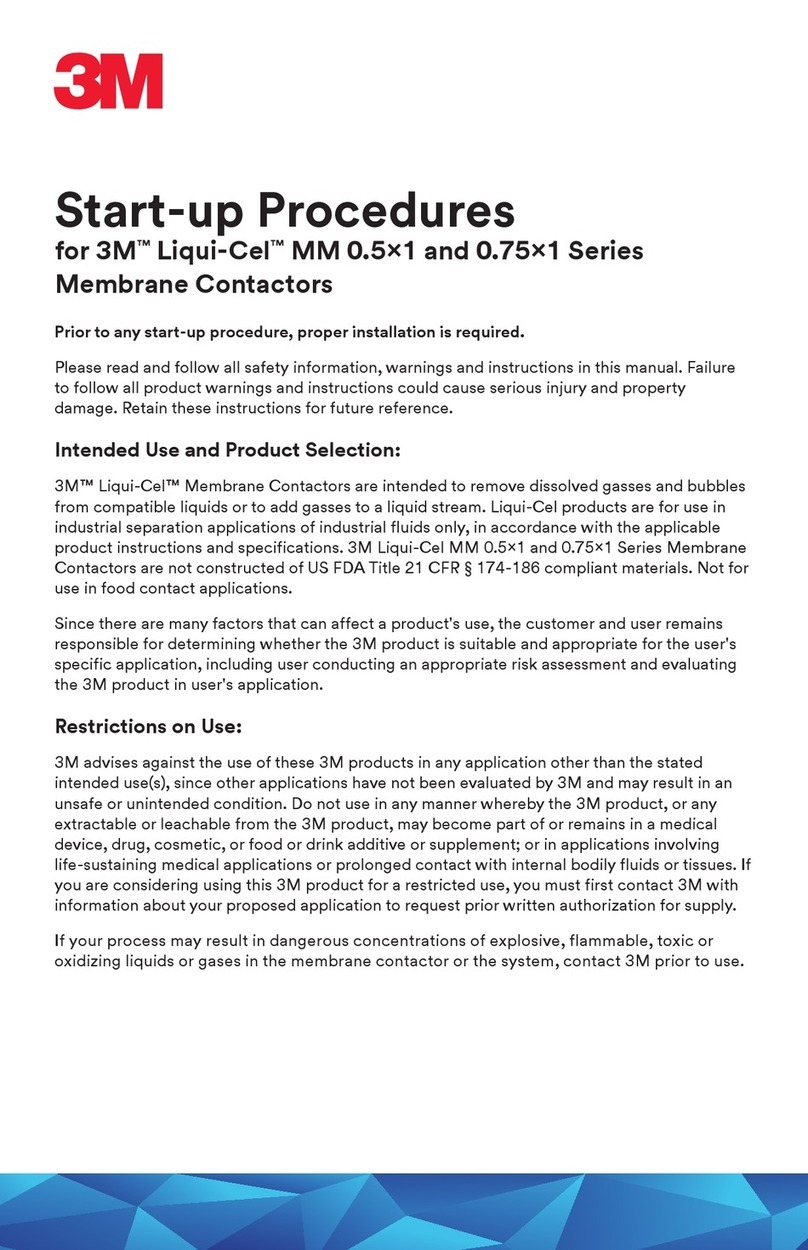

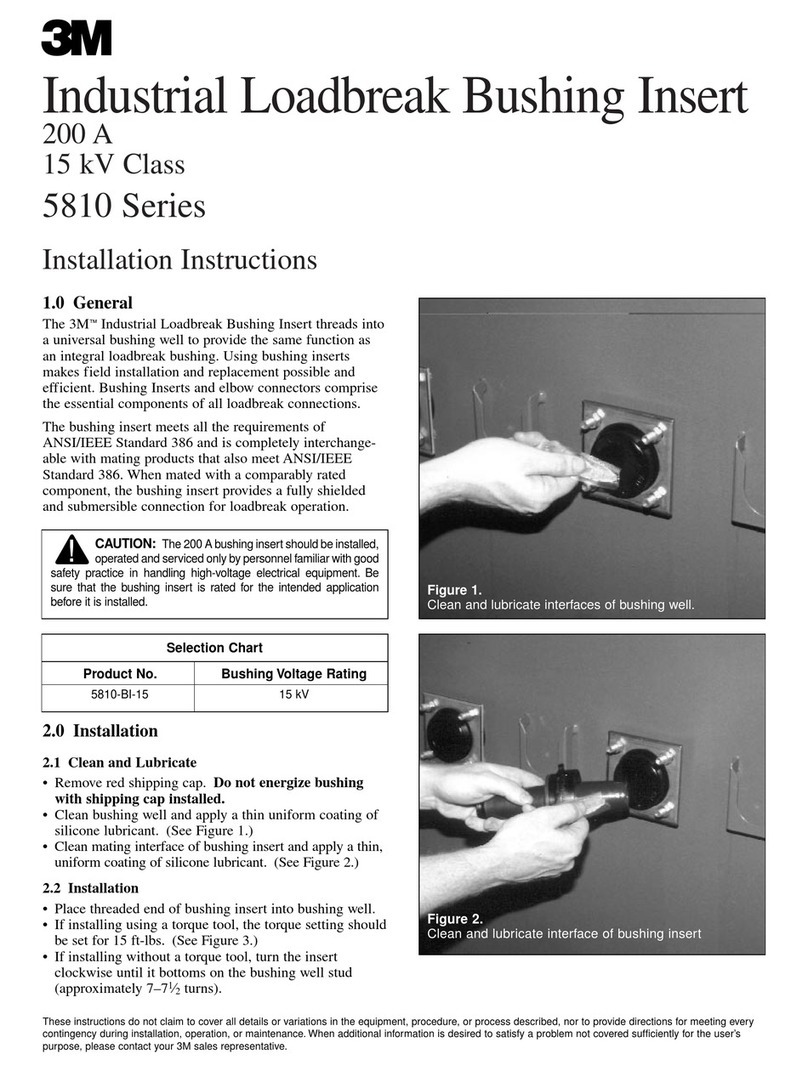

Figure 1.

Loadbreak Bushing Insert with latch indicator ring and “All Copper Current

Path”for application in transformers, switches and other apparatus.

1.3 Production Tests

Tests conducted in accordance with ANSI/IEEE

Standard 386:

•ac 60 Hz 1 Minute Withstand 34 kV

•Minimum Corona Voltage Level 11 kV

Tests conducted in accordance with manufacturer’s

requirements:

•Physical Inspection

•Periodic Dissection

•Periodic Fluoroscopic Analysis

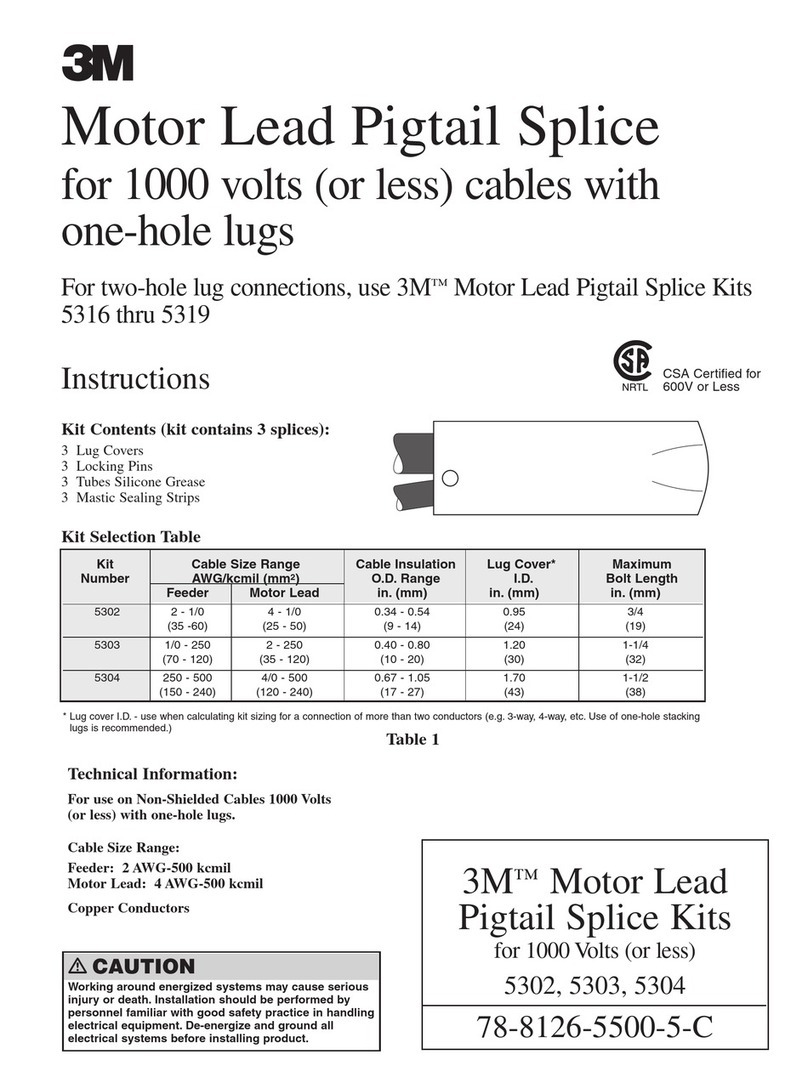

TABLE 2

Current Ratings and Characteristics

Current ratings and characteristics are in accordance with ANSI/IEEE

Standard 386.

Description Amperes

Continuous 200 A rms

Switching 10 operations at 200 A rms at 14.4 kV

Fault Closure 10,000 A rms symmetrical at 14.4 kV after

10 switching operations for 0.17 s

Short Time 10,000 A rms symmetrical for 0.17 s

3,500 A rms symmetrical for 3.0 s

Description kV

Standard Voltage Class 15

Maximum Rating Phase-to-Phase 14.4

Maximum Rating Phase-to-Ground 8.3

ac 60 Hz 1 Minute Withstand 34

dc 15 Minute Withstand 53

BIL and Full Wave Crest 95

Minimum Corona Voltage Level 11

Voltage ratings and characteristics are in accordance with ANSI/IEEE

Standard 386.

TABLE 1

Voltage Ratings and Characteristics