3

2.0 Features

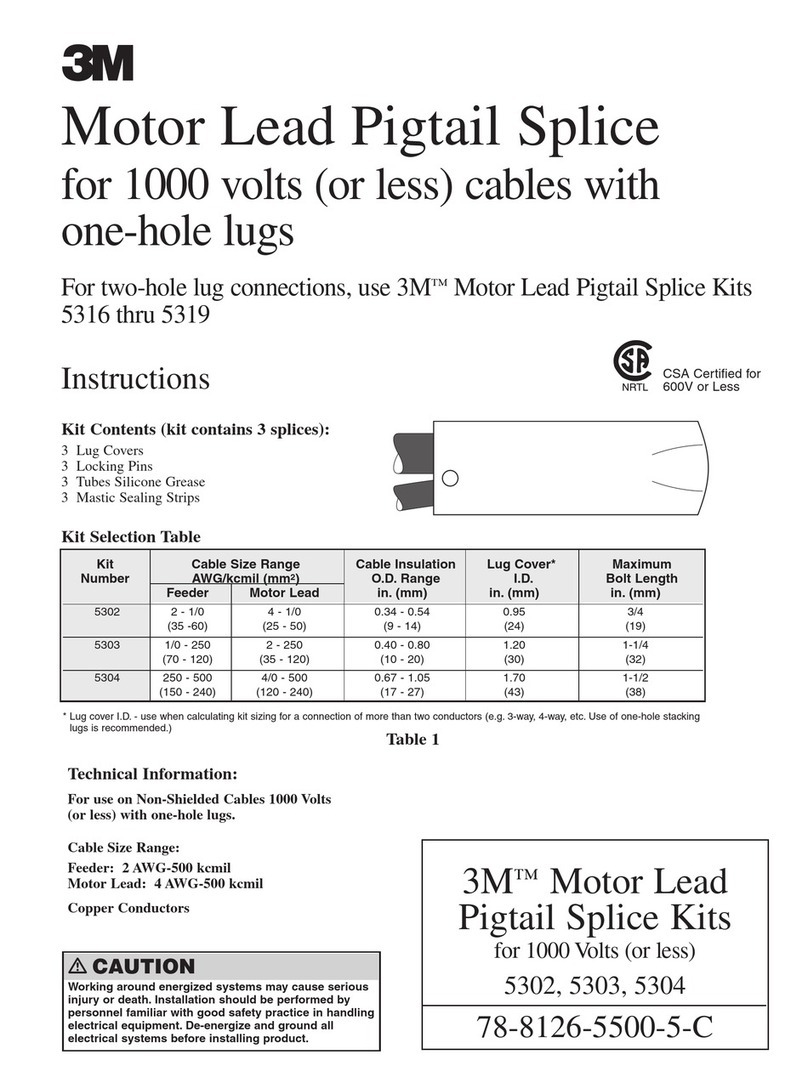

The 3M™ VF-45™ Fiber Optic Connector Quick Install Kit is used to field terminate VF-45 multimode and single

mode sockets. The VF-45 sockets are dual optical fiber connectors that are primarily used in fiber-to-the-desk LAN

applications. The duplex fibers are terminated simultaneously using this tool kit.

The VF-45 Fiber Optic Connector Quick Install Kit has the following hardware features and benefits:

a) Carrying case for ease of use with compartments for all required tools.

b) Integrated installation tool comprising:

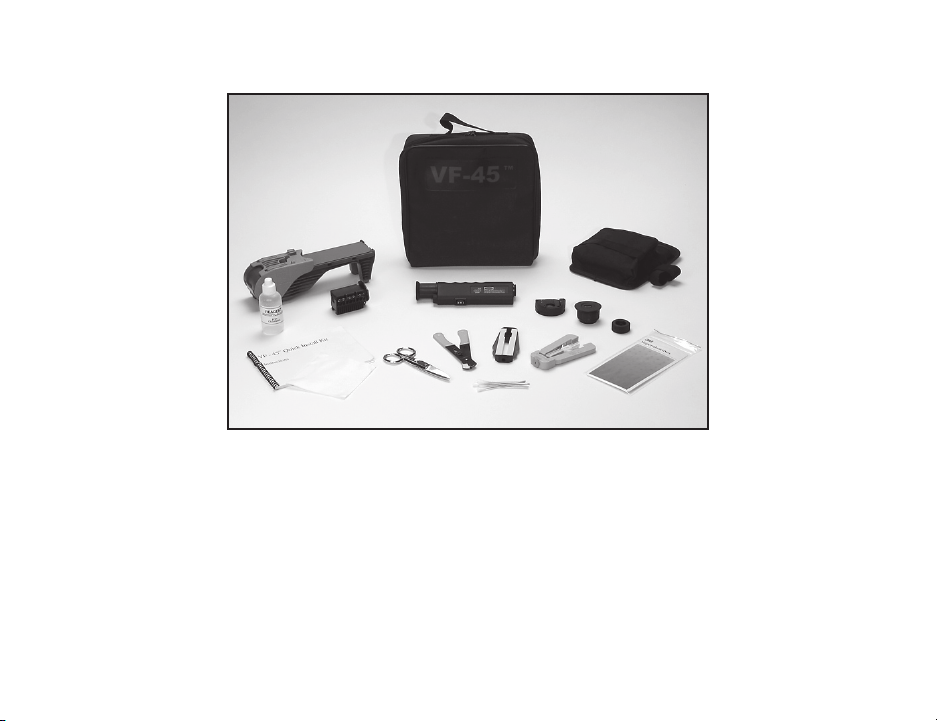

• Easy scribe and break of fibers to prepare for polishing

• Fiber stub catcher

• Slip resistant polishing base

• Tool pouch storage for all hand tools

• Adhesive backed lapping film for polishing

• Versatile dual illumination microscope with adapters for inspection of:

1) Polishing puck end-face

2) Patch cord plug-fibers

3) Standard ferruled connectors

c) All fiber measurements made with hand tools (no precise measuring)

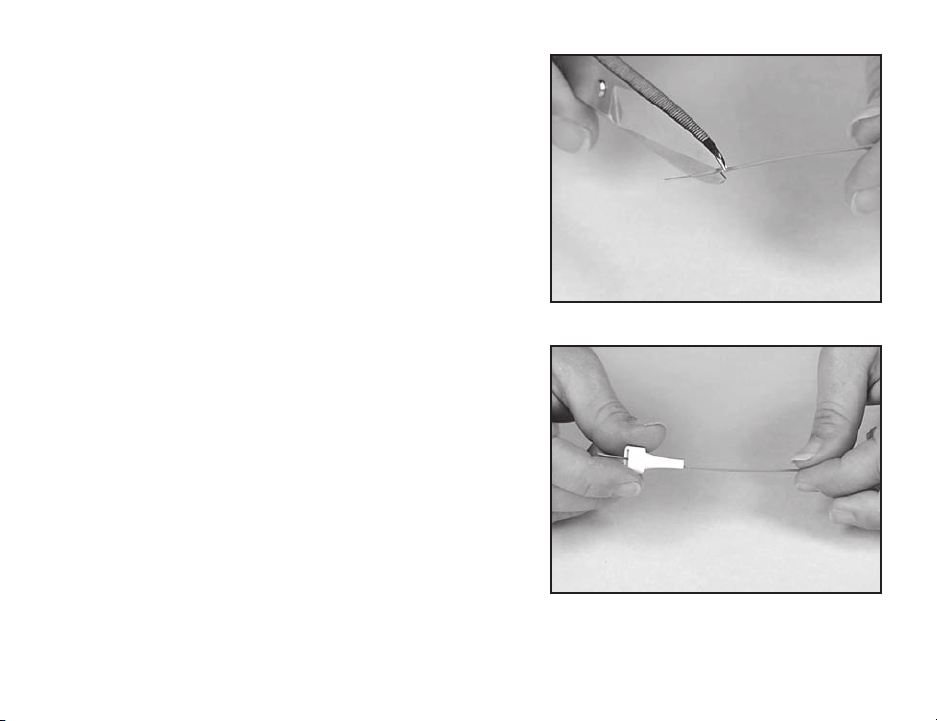

d) Easy fiber insertion and socket assembly

e) Audible click verifies socket assembly

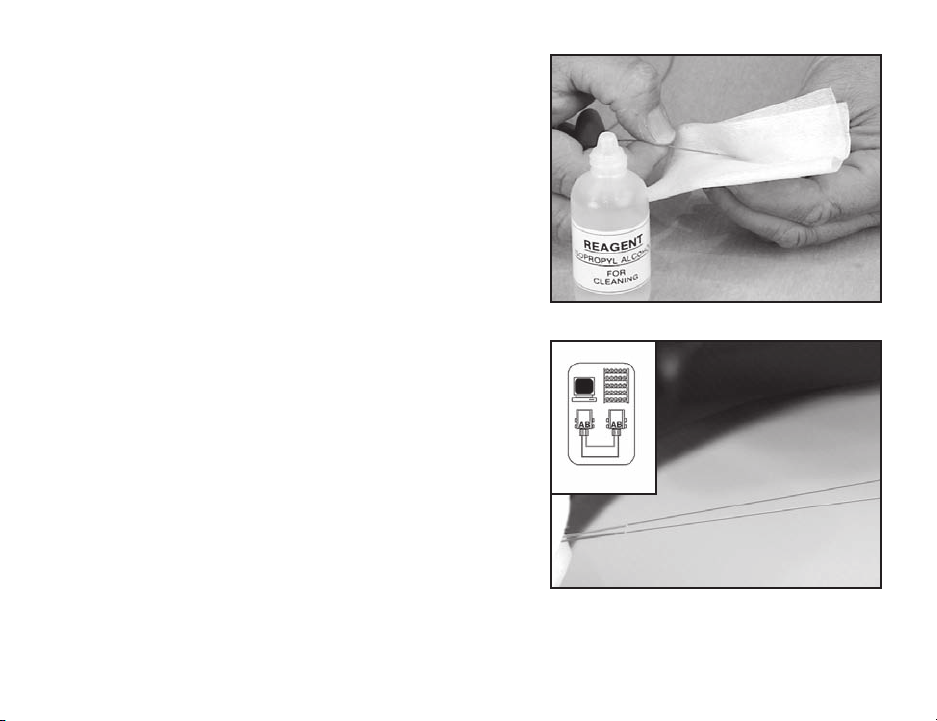

f) Cleaning with cotton swab

g) Quick assembly of VF-45 socket

h) Angle polishing for low loss, low reflectance connections

i) Replaceable polishing pad

j) Replaceable scribe assembly

k) Replaceable polishing face

Caution: Wear safety glasses during all work operations.