9

78-8140-3820-0-B

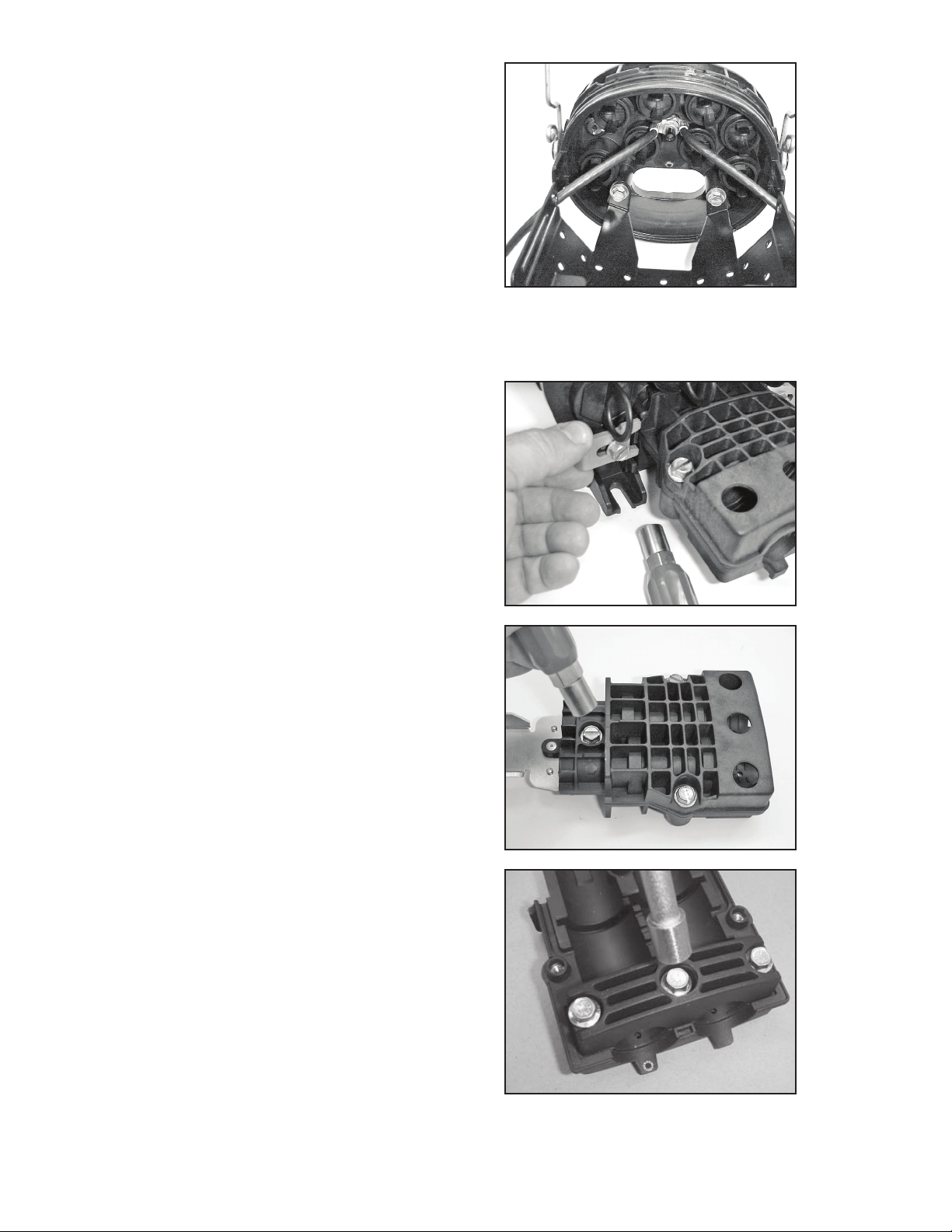

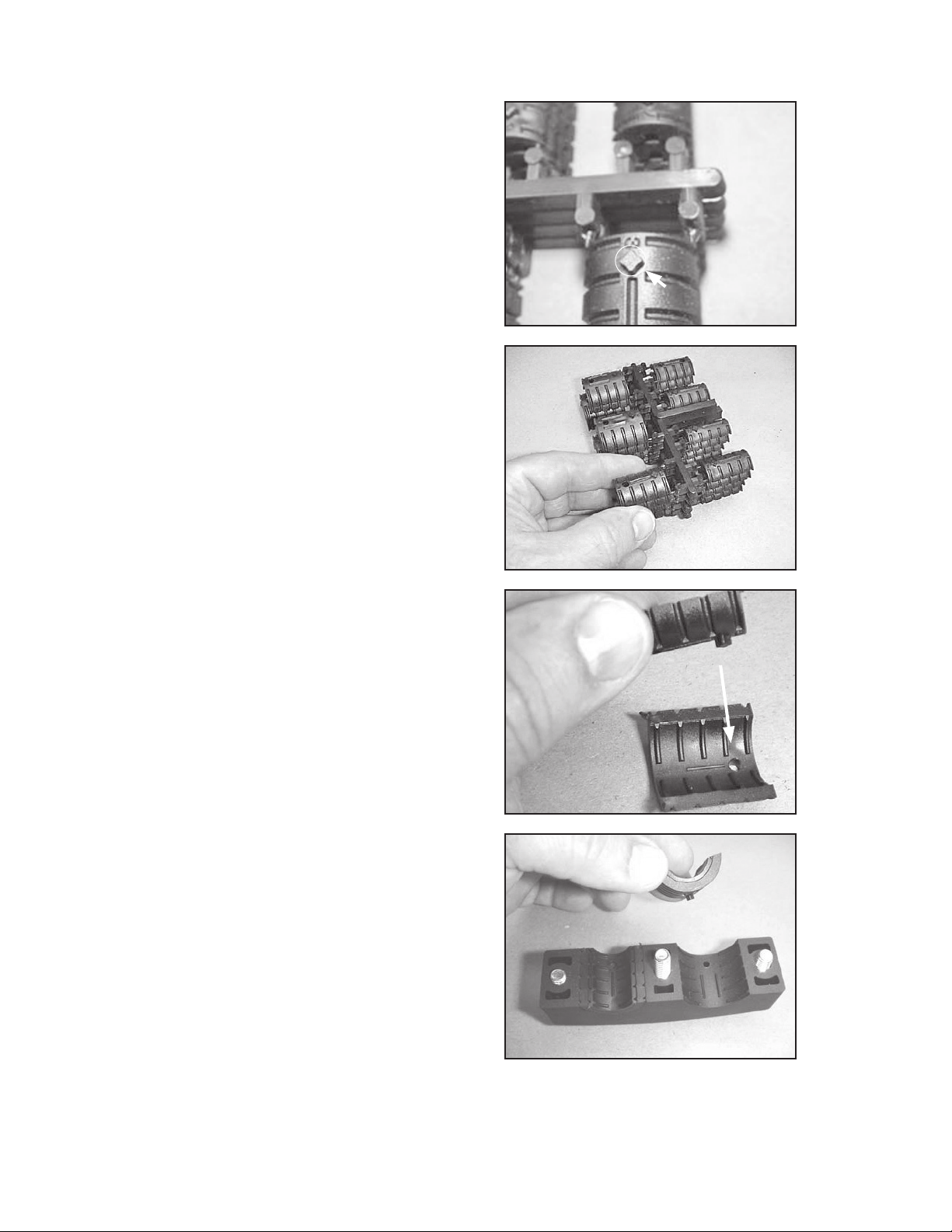

7.5 Assemble the clamp shell(s) onto the bottom

half of the cable housing. Note the orientation

of the pin and socket and assemble accordingly.

Note: Different-sized cables may require different-

sized clamps. Ensure that the correct clamp

set matches the cable when assembling in the

bottom housing and the cable clamp.

8.0 Cable Seal Installation

8.1 First clean the cable sheath thoroughly using an

alcohol wipe. Make sure the cable sheath is free

of any grease or dirt.

Note: Carefully follow health, safety and environmental

instructions as given on the Material Safety Data

Sheet for the alcohol wipe.

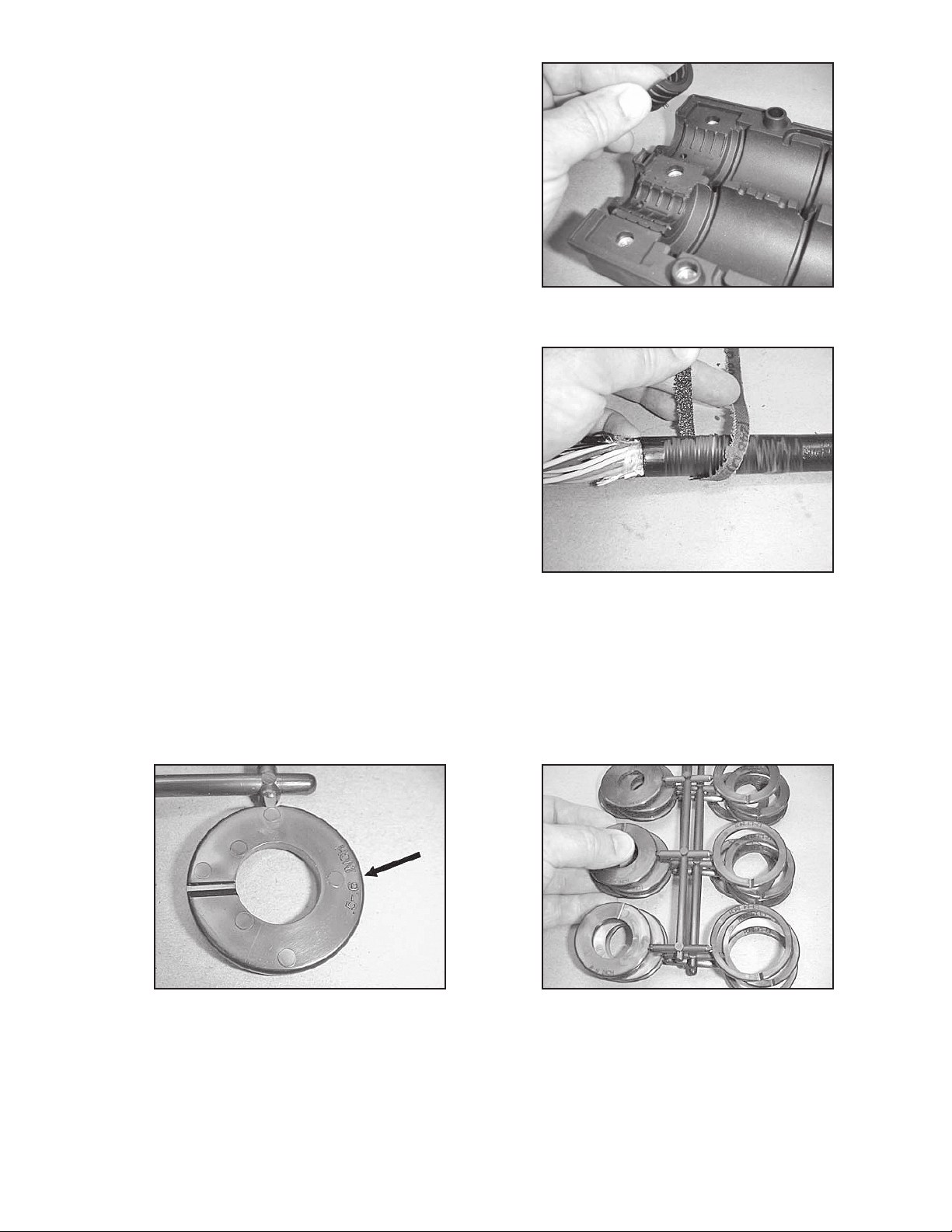

Scuff the first 3" of each cable sheath using

supplied sheath scuff. Ensure the cable is

completely scuffed around the perimeter of the

cable.

Hint: Scuffing is easier if you tear the sheath scuff in

narrow strips along the length of the strip.

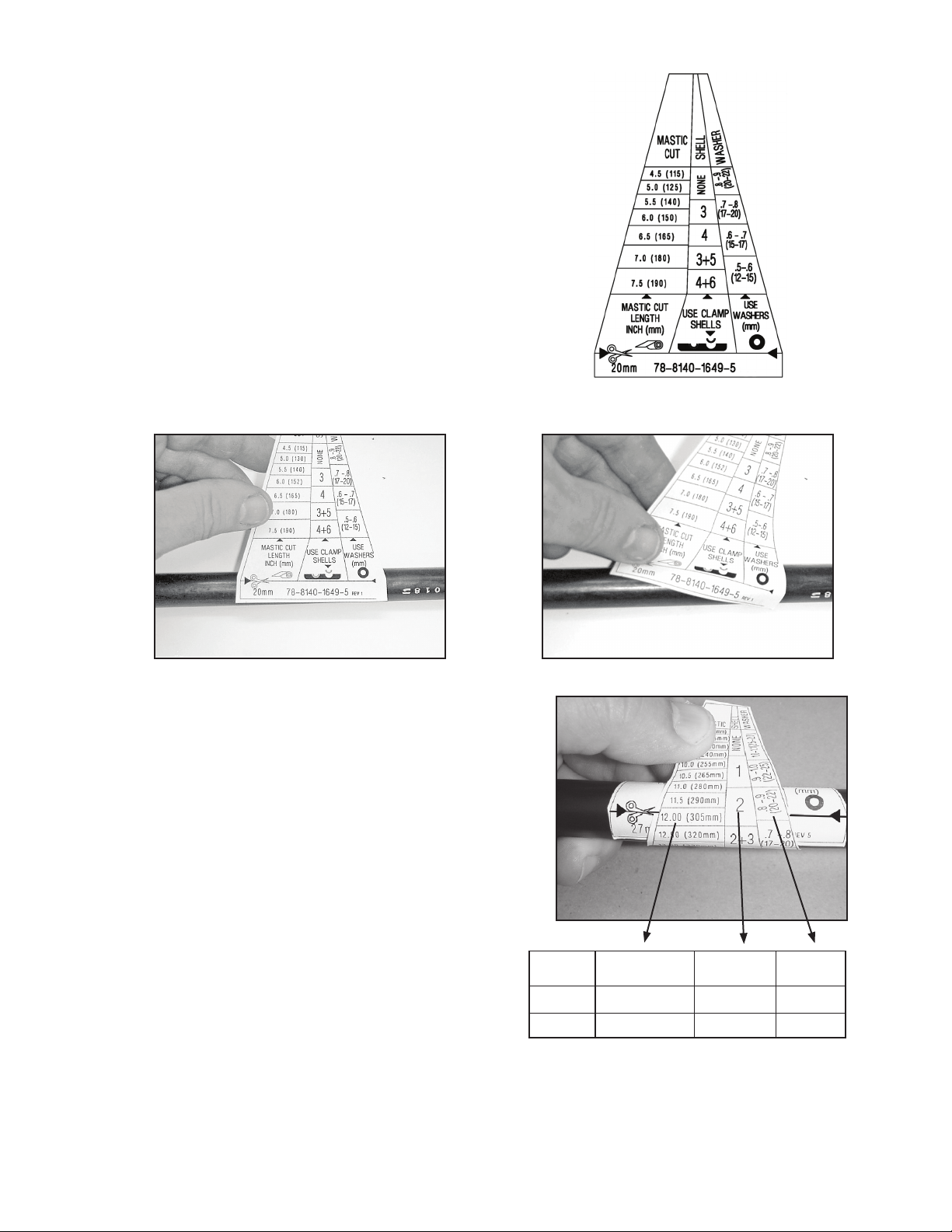

Washer Selection

8.2 Locate and remove two washers on parts trees for each cable (four washers total). Note that washer

sizes are labeled on the washer as shown below. Note that inches are on one side of the washer and

millimeters are on the other side.

Note: See chart in section 6.2 for required washer.