Model AC-900 Automatic Mixer

AC-900 Manual page 4

[REV:B] 03/17/2015

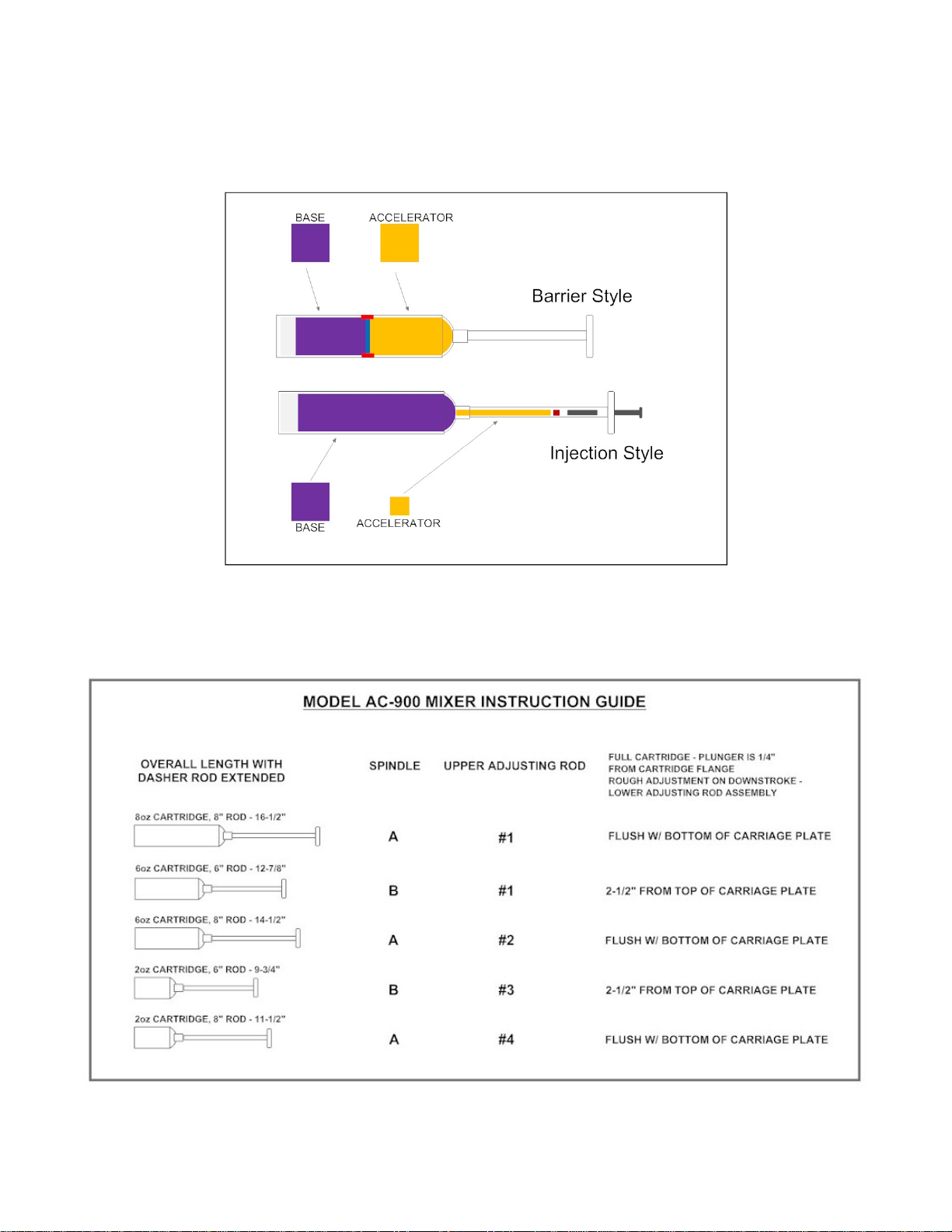

The instruction plate attached to the left-hand side of the box lists the cartridge size/dasher rod

size, the proper spindle number and upper stroke adjustment rod to use, and the correct setting in

inches for the down stroke adjustment rod. This is a guide for full kits only. Most likely, the

sealant you will be mixing is not a full kit. Select kit to be mixed and prepare for mixing as

stated in the instructions on side of the box OR follow instructions below for a non-full kit /

short package.

Determine if cartridge is “fully packaged” or is a short package and make appropriate down

stroke adjustment as shown on instructions on side of box. A cartridge is “fully packaged”

when material in dasher rod has been injected or barrier has erupted, and the rim of plunger is

3/16” from end of cartridge while dasher rod is pushed all the way to touch plunger. If cartridge

is not fully packaged, shorten down stroke by the difference in inches of the location of the

plunger between a fully packaged cartridge and the actual location of the plunger. OR you can

perform the following under “Full Instructions”:

WARNING - Do not operate this device in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust.

WARNING - If materials spill, disconnect power and follow Safety Data Sheet (SDS) for spill clean-

up procedure.

WARNING – Dispose of mixer in accordance with all applicable regulations.

Quick Instructions: If you are not familiar with the mixer, please proceed to “Full Instructions”

1. Ensure the “OFF / MIX” switch on the top of the mixer is in the “OFF” position

2. Remove air cylinder cap assembly from carriage plate and insert cartridge, rod end first,

through mounting hole in carriage plate.

3. Pull dasher rod down onto pins of the drive spindle.

4. Grasp cartridge and pull down until it is fully seated in carriage plate; then install and lock air

cylinder / cap assembly by twisting pins (by hand only!) into carriage plate “ears”.

5. Turn timer knob to desired number of minutes for mixing. (If mix period is less than two

minutes, timer must be turned past two minutes then returned to the desired time); keeping

fingers and all extremities clear, flip switch on top of machine to “MIX” position which will

begin the cycle of machine and mixing of material in cartridge.

6. When timer has completed its cycle, both air and electric power will be shut off and cartridge

may be removed.