1.0 General

The 3M™Integrated Protection Terminal 4990IPT

provides electrical protection and a termination point

for outside plant cable and indoor house wiring.

The 3M terminals 4990IPT series are Underwriters

Laboratories (348X) Listed.

Note: For Underwriters Laboratories Compliance, the

3M Integrated Protection Terminals series 4990IPT

may only be used with the cover provided.

Available 3M 4990IPT indoor terminals

4990IPT/100-100/SC-A IBET 100 pair max - 100 pair installed

with 3M™710 modules

4990IPT/100-50/SC-A IBET 100 pair max - 50 pair installed

with 3M 710 modules

4990IPT/100-25/SC-A IBET 100 pair max - 25 pair installed

with 3M 710 modules

4990PT/100-100/GBM-A IBET 100 pair max - 100 pair installed

with 3M™MS²™Modules

4990IPT/100-50/GBM-A IBET 100 pair max - 50 pair installed

with 3M MS² modules

4990IPT/100-25/GBM-A IBET 100 pair max - 25 pair installed

with 3M MS² modules

1.1 3M™Indoor/Outdoor Integrated Protection

Terminal 4990IPT parts and components

a. Block tails with gelled 3M™Quick Connect

System (QCS) 2814 modules, 3M™710

Gelled Splicing Connectors and 3M™MS2™

Gelled Splicing Connectors 4005 GBM

b. Splice chamber with strain relief for

entrance cable

c. Insulated #6 ground wire for entrance

d. Internal bottom-mounted three point

ground bar

e. Binding post log label

f. 3M™Single Pair Test Probe 2827

g. Lockable protective cover

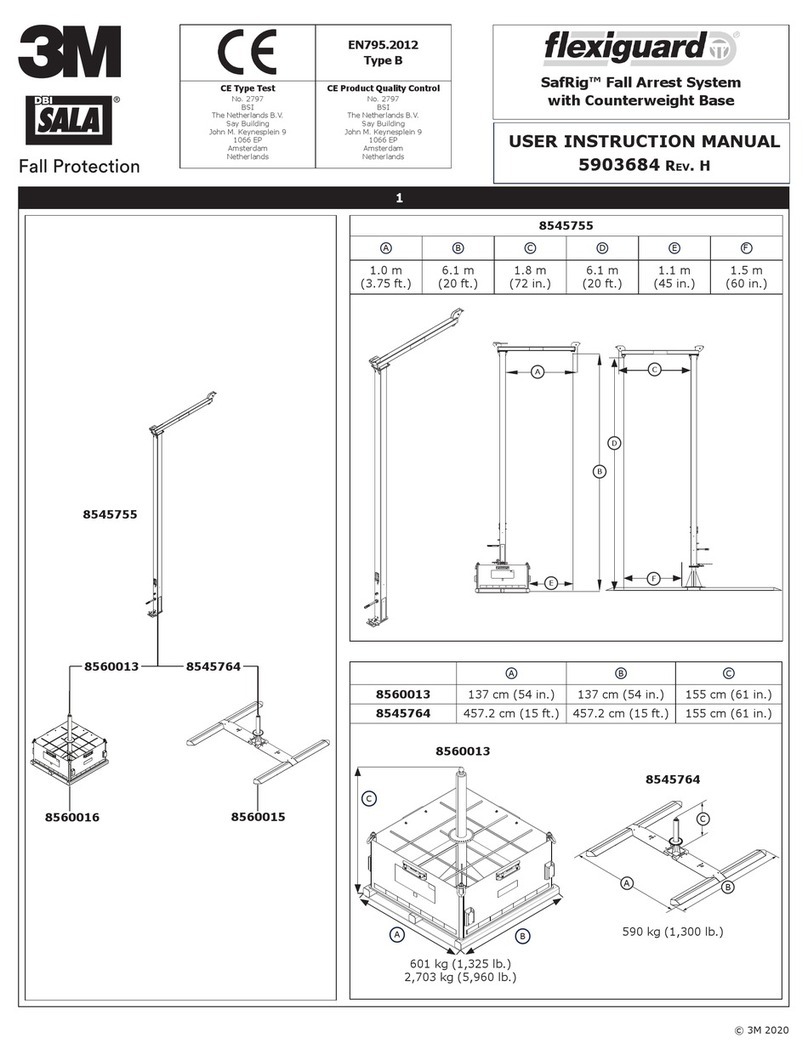

1.2 3M Integrated Protection Terminal Dimensions

Model Height Width Depth

4990IPT-100 13" (330 mm) 13.5" (343 mm) 6" (152 mm)

3M™Indoor/Outdoor Integrated Protection Terminal

4990IPT - 100 pair

1.3 Protector Specifications

Use only UL Recognized 3M™Single Pair

Protectors 2814SPD in the 3M 4588IPT terminals.

1.4 Materials and Special Tools Needed to Splice

3M 710 Splicing System tooling plus 710 SC

Modules, 3M MS2Splicing System tooling,

plus MS24005-GBM Modules. All versions are

terminated on 3M 710 or MS2splice modules.

2.0 3M Indoor/Outdoor Building

Entrance Terminal IPT Location

and Mounting

2.1 Locate the terminal according to your company’s

standard operating procedure. Consider the

following points:

a) Locate the terminal inside/outside the

building/room as close as possible to the

MGN or ground wire source.

b) Locate the terminal inside/outside the

building/room as close as possible to the

cable entrance.

c) Locate the terminal on a firm mounting

surface where it will be accessible to all

technicians at all times.

d) Locate the terminal where it can be reached

without a ladder.

e) Avoid locating the terminal where it projects

out in a hazardous manner.

278-0015-3160-3-AOctober 2016