AMC

AMCAMC

AMC-

--

-1022M

1022M1022M

1022M

iii

TABLE OF CONTENTS

Page

TABLE OF CONTENTS...................................................................................................III

WARRANTY ................................................................................................................... IV

LIABILITY................................................................................................................................................................IV

MODIFICATIONS AND SUBSTITUTIONS........................................................................................................IV

PRODUCT RETURN UNDER WARRANTY ......................................................................................................IV

SPECIFICATIONS............................................................................................................ V

1 INTRODUCTION........................................................................................................ 1

1.1 GENERAL DESCRIPTION......................................................................................................................... 1

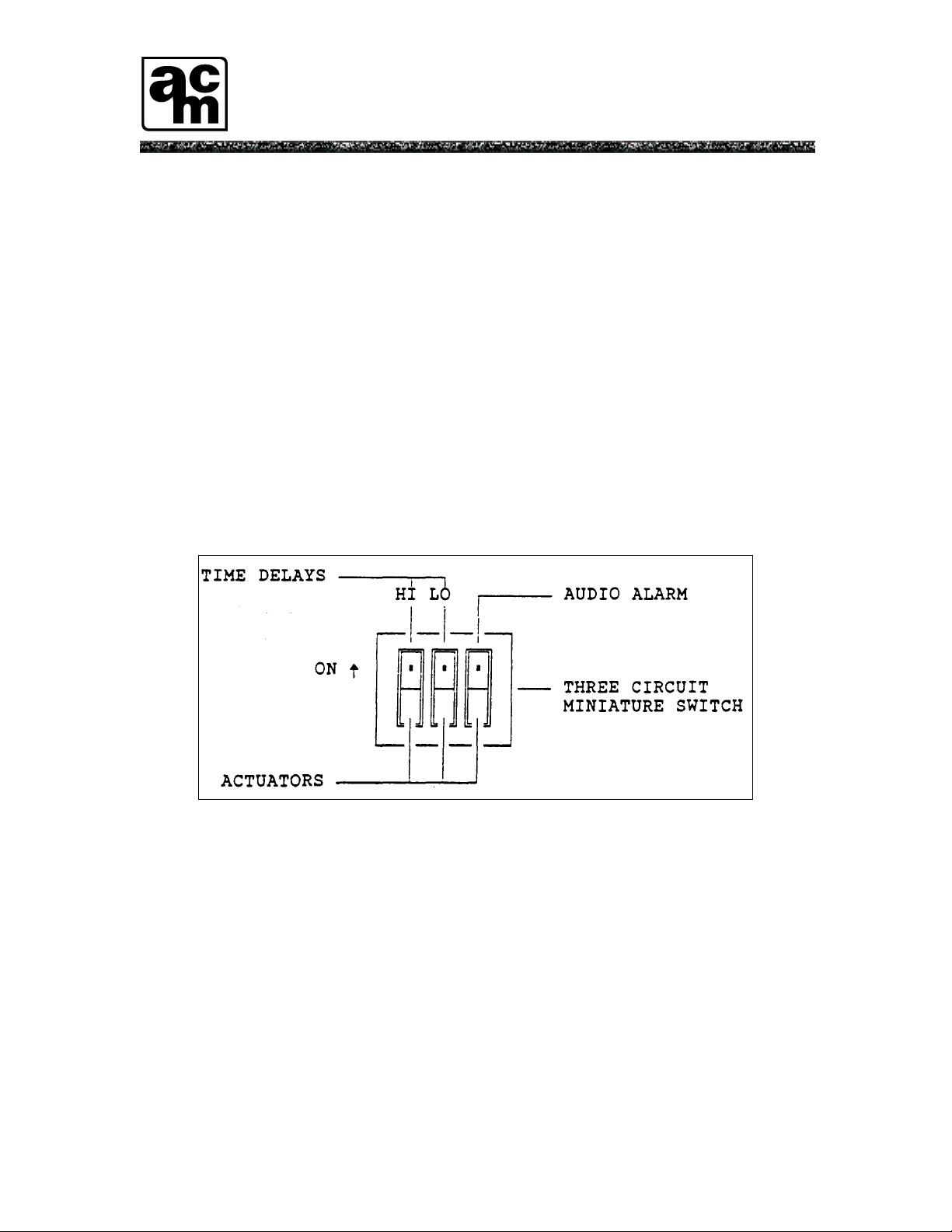

Figure 1.1 Three circuit miniature switch........................................................................................... 2

Figure 1.2 AMC-1022M series monitor, front panel......................................................................... 3

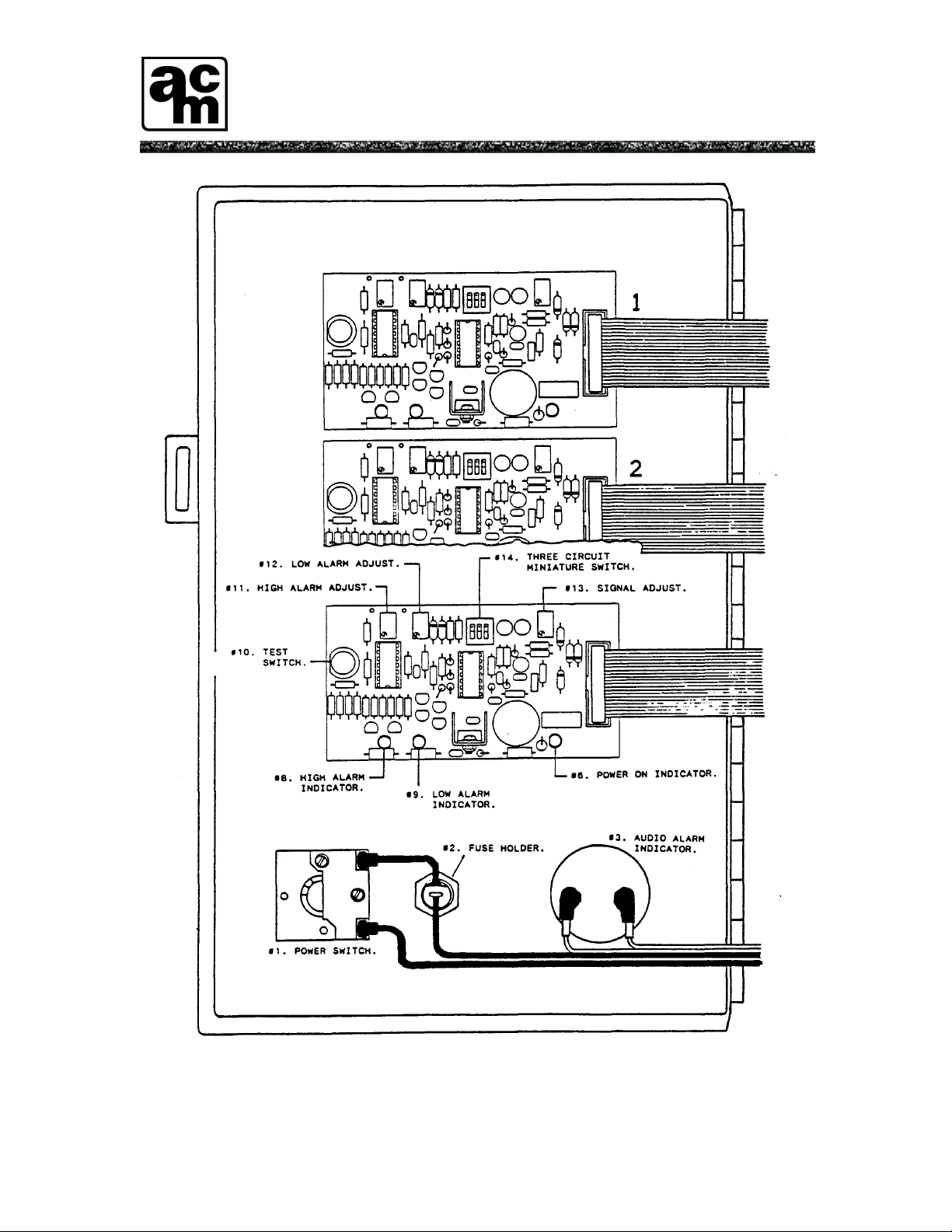

Figure 1.3 AMC-1022M series monitor, inside front panel. ............................................................. 4

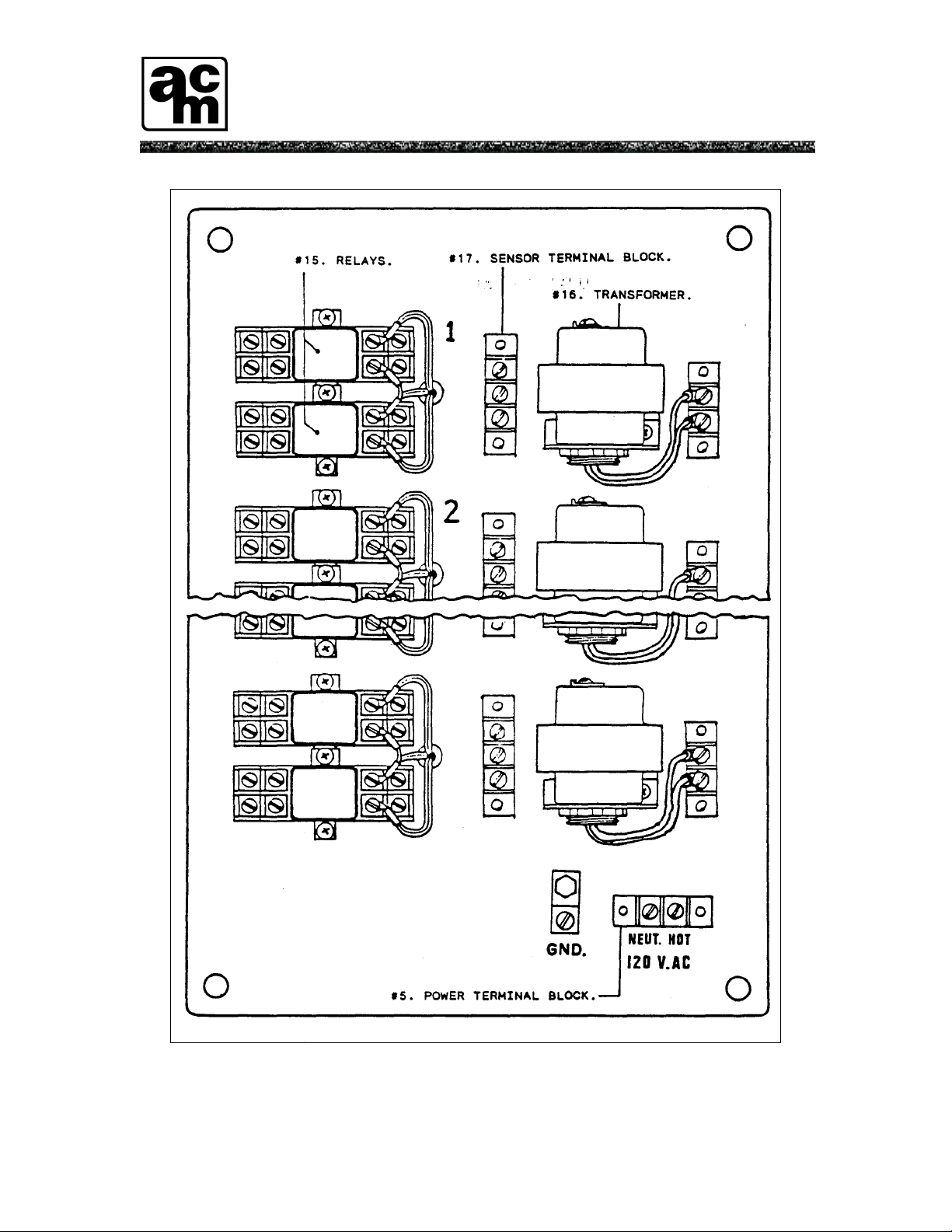

Figure 1.4 AMC-1022M series monitor, inside power/relay panel. .................................................. 5

2 INSTALLATION......................................................................................................... 6

2.1 LOCATION AND MOUNTING................................................................................................................. 6

2.2 WIRING OF THE MONITOR & SENSORS AND/OR TRANSMITTERS........................................... 6

Figure 2.1 Monitor power supply connections. ................................................................................ 7

2.3 SCHEDULE OF CABLE SIZES ................................................................................................................. 7

Figure 2.2 Monitor mounting dimensions. ........................................................................................8

Figure 2.3 remote sensor/transmitter wiring layout (one channel) .................................................... 9

Figure 2.4 Relay contact arrangement ............................................................................................. 10

3 OPERATION AND CALIBRATION ....................................................................... 11

3.1 OPERATION............................................................................................................................................... 11

3.2 CALIBRATION.......................................................................................................................................... 11

3.2.1 APPLYING CALIBRATION GAS SAMPLE(S) ................................................................ 11

3.2.2 ADJUSTMENTS.................................................................................................................. 11

Figure 3.1 Trimmer adjustments and test point locations................................................................. 13

4 MAINTENANCE....................................................................................................... 14

4.1 GENERAL................................................................................................................................................... 14

4.2 VERIFICATION OF OPERATION.......................................................................................................... 14

4.3 SENSOR REPLACEMENT....................................................................................................................... 14