78-0013-1813-4-A 3

2.0 Terminal Location and Mounting

2.1 Locate the terminal according to standard

operating procedures. Consider the following

points:

a) Locate the terminal inside the building as

close as possible to cable entrance.

b) Locate the terminal on a firm mounting

surface where it will be accessible to the

technicians at all times; where it can be

reached without a ladder; and where it will

not project in a hazardous manner.

c) Observe caution when exposing the terminal

to chemicals in liquid or vapor form as they

may damage the plastic components.

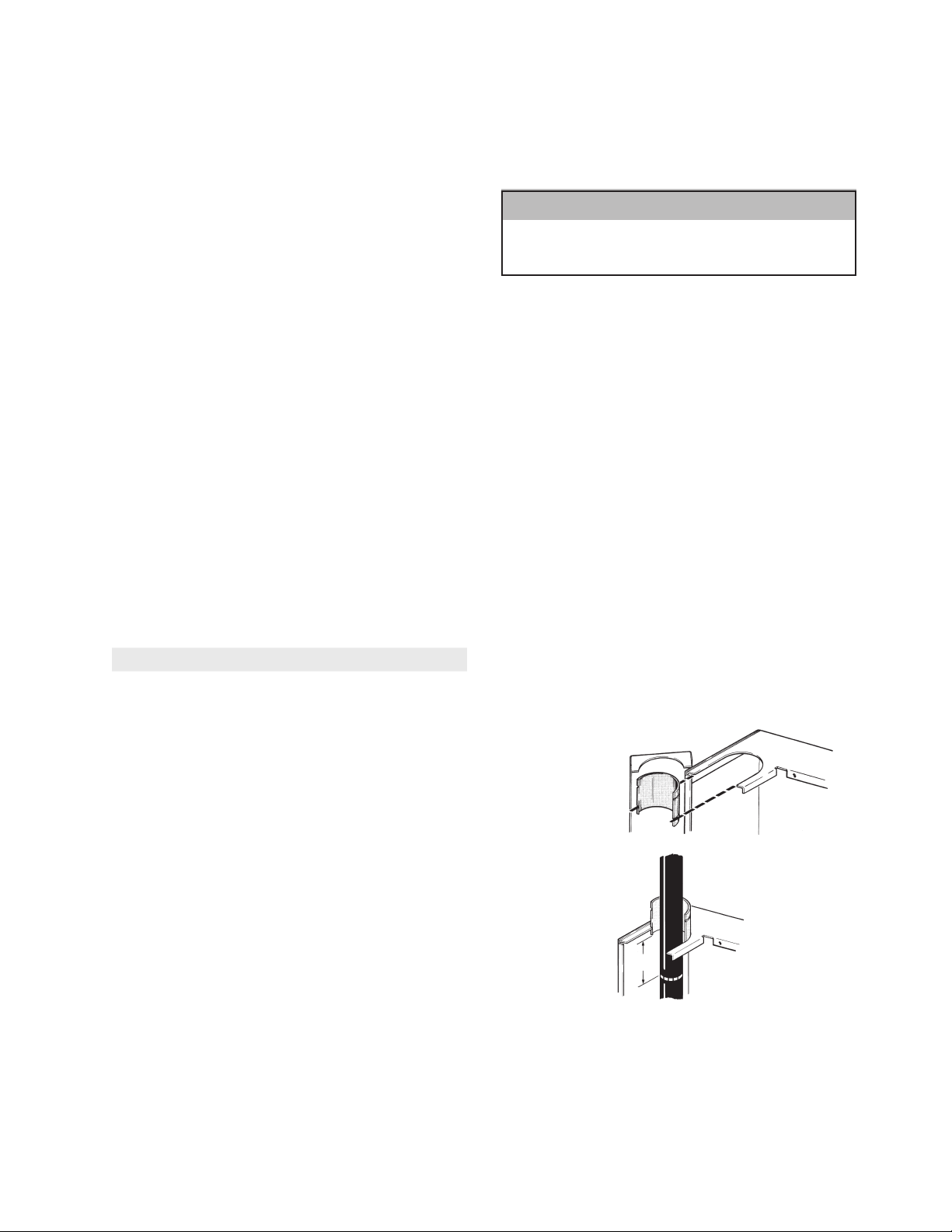

CAUTION

Avoid locations near flammable materials, ignitable gases,

dust, moisture, temperature extremes, moving machinery,

electric light and power circuits, and electrical equipment.

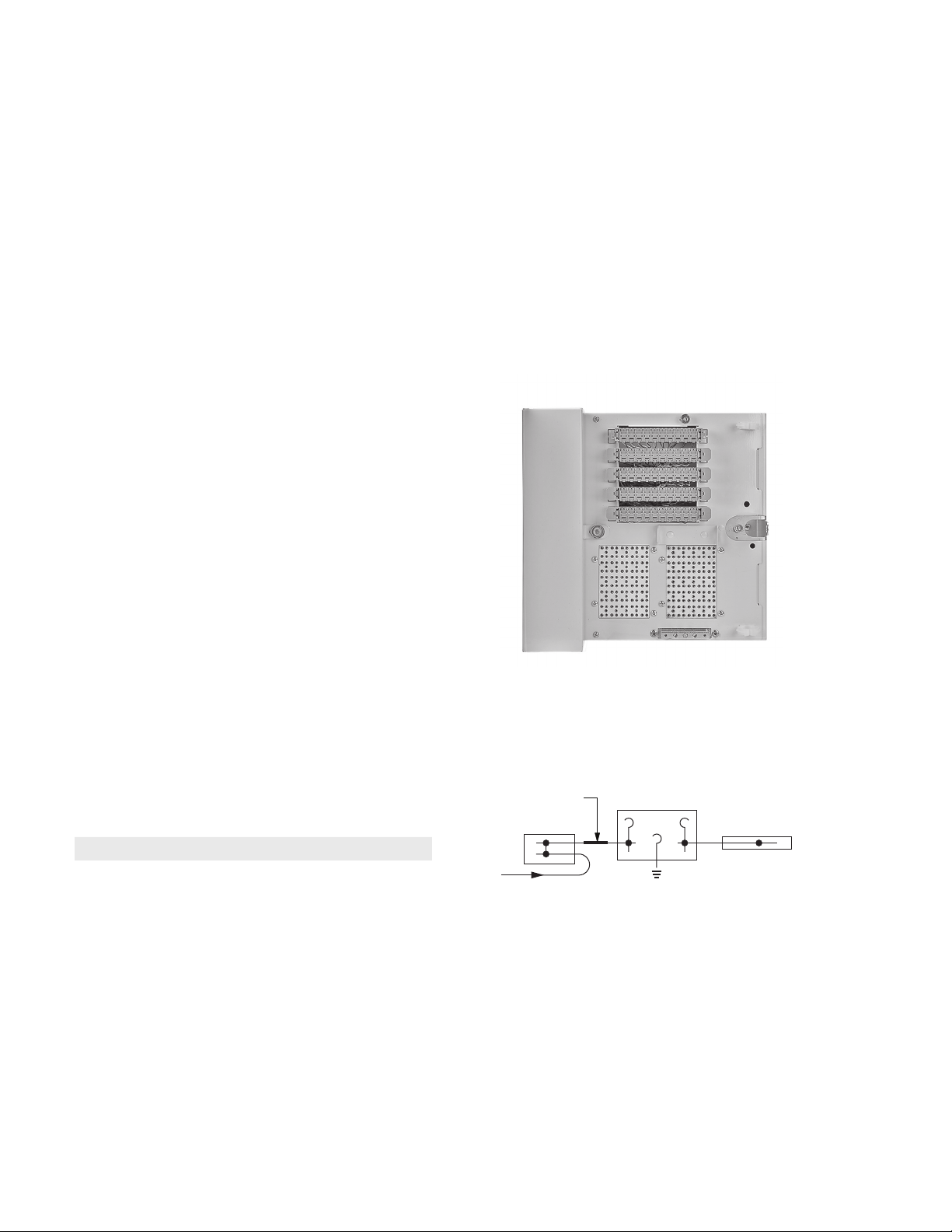

2.2 Open the splicing chamber by loosening the bolt securing the splicing chamber door. Open the splicing chamber

door. (See-fig. 7.02)

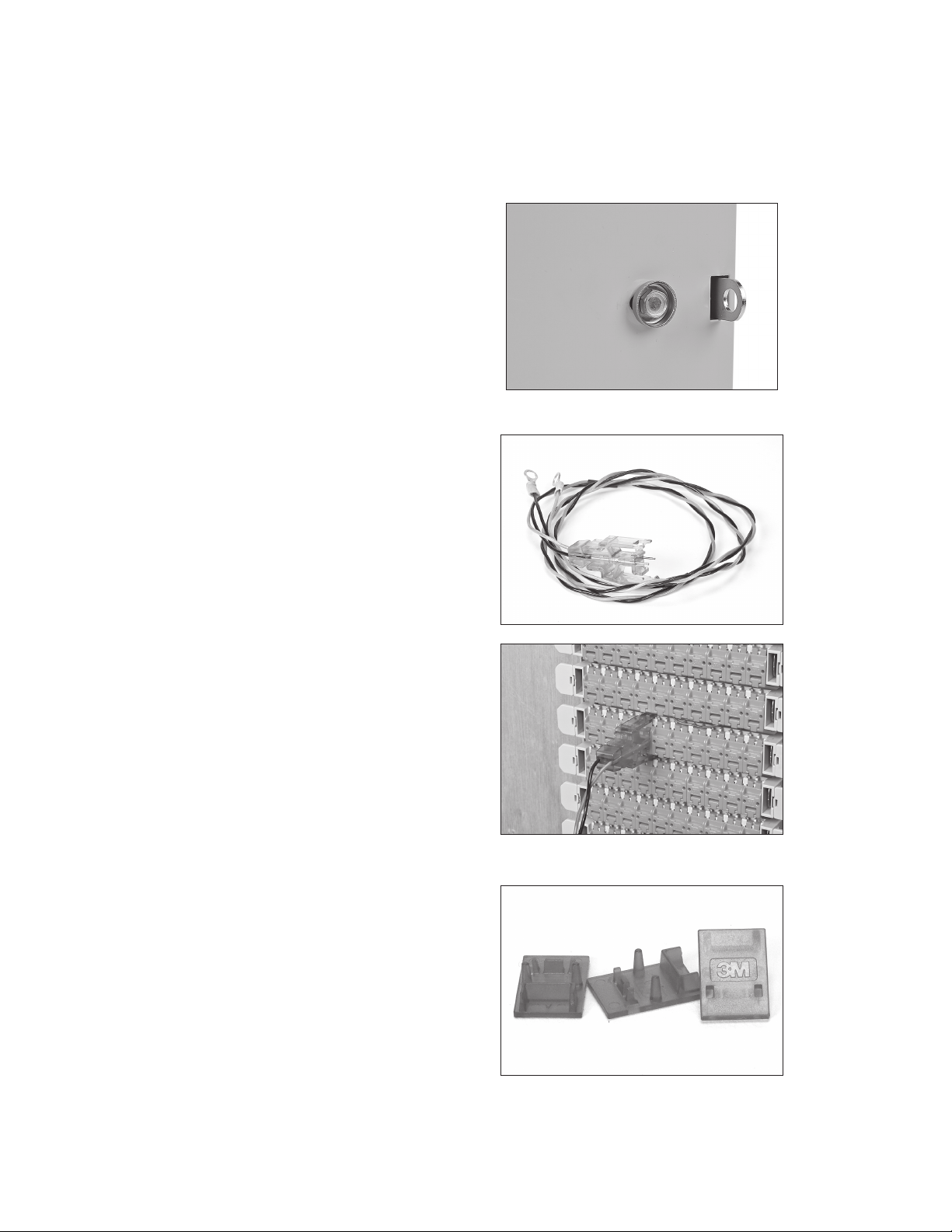

2.3 Pull the preterminated short stub, insulated ground wire, and accessories out of the splicing chamber.

2.4 Mount the terminal in designated position with the three mounting screws provided.

2.5 Remove the jumper wire retaining ring from poly bag and install in faceplate.

3.0 Feeder Cable Preparation and Strain Relief

3.1 Feeder cable diameters for the 3M™ Indoor Building Entrance Terminal (IBET) 4588V-QCS Series

PET Pair Count

Feeder Cable

Minimum Maximum

Diameter Diameter

25 .42" 1.08"

50 .63" 1.45"

If the cable diameter is smaller than the minimum, use 3M™ 130C tape to build up to the minimum.

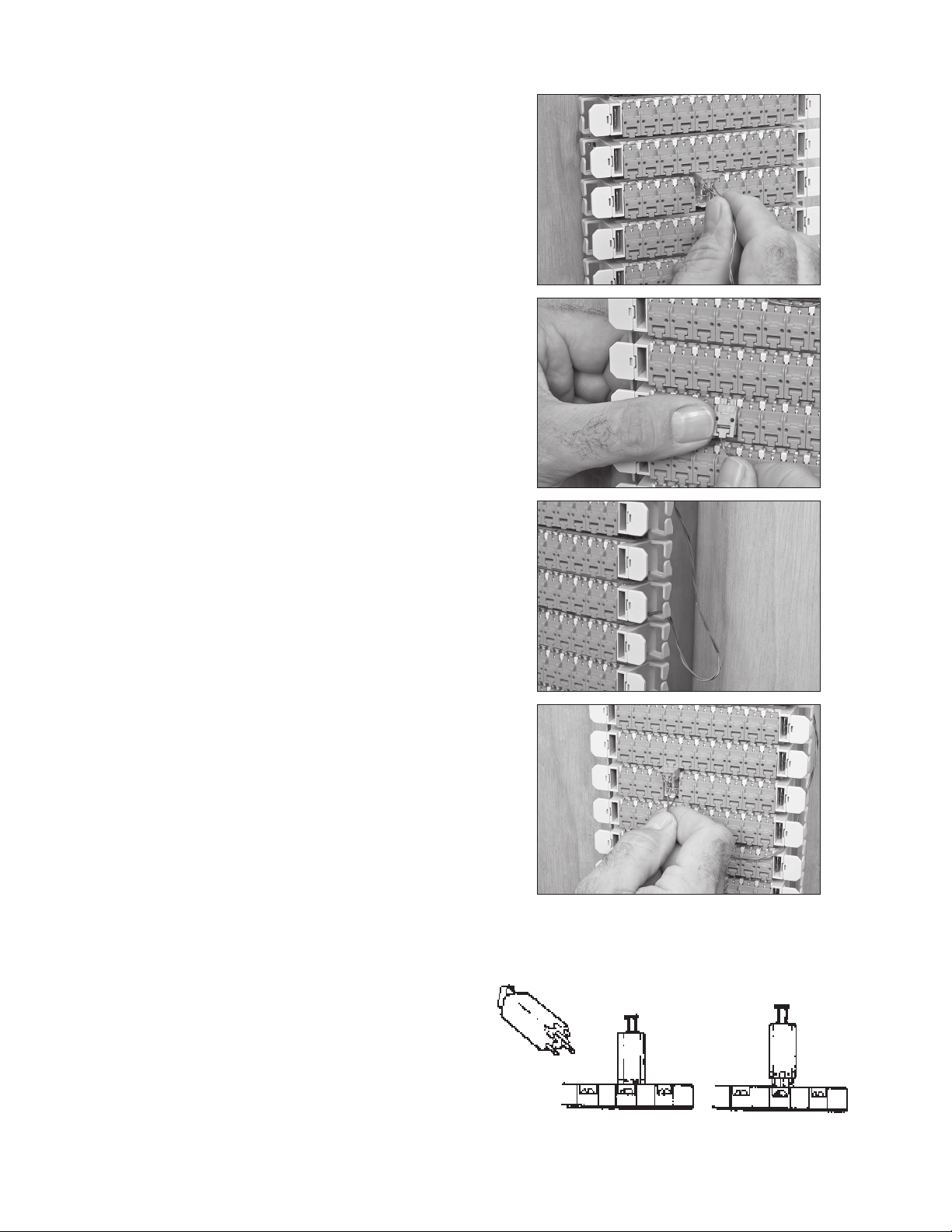

3.2 Run the feeder cable 24" past the IBET terminal

cable entry port.

3.3 Slide the 3M™ Pull ’N’ Shrink Tube (PST) on the

end of the cable with the pull-tab away from the

IBET terminal and temporarily keep it out of the

way.

3.4 With the groove toward the IBET terminal and

long end toward the cable, snap the cable gland

halves around the cable. Slide the gland into the

entry port of the IBET terminal.

3.5 Measure 2" of sheath past the gland inside the

IBET terminal. Pull the gland and cable out of the

IBET terminal.

843014

2"

25-50

pair

100 pair