3S SL-R60S User manual

www.3SLift.com

File No. Version Date

TD-RND-TF-065 A 2020.8

EN

SL-R60S Fall Arrester

Operation And Maintenance Manual

Ficont Industry (Beijing) Co., Ltd.

1005, SK Tower, No.6 Jia, Jianguomenwai Avenue, Beijing, China

No. 15, Chuangyi East 2nd Road, Xiji Development Zone, Tongzhou, Beijing, China

Tel: +86 10 69597866

E-mail: [email protected]

Ficont Industry (Tianjin) Co., Ltd.

No. 8, Cuiyuan Road, Wuqing Development Zone, Tianjin, China

Tel: +86 022 22140477

E-mail: [email protected]

3S Americas, Inc.

2840 Guilder Drive, Suite 100, Plano Texas, 75074 USA

Tel: +1 312 6232662

E-mail: [email protected]om

3S Europe GmbH

Erdmannstr. 10, 22765 Hamburg, Germany

E-mail: [email protected]

3S Lift India Private Limited

No. 2C Shyams Garden, Khadar Nawaz Khan Road,

Nungambakkam, Chennai – 600006, India

E-mail: [email protected]

Limited Warranty ................................................................................. 1

1. Precautions .......................................................................................2

2. Product Description & Components ............................................5

3. Specifications...................................................................................6

4. Marking..............................................................................................7

5. Operation ..........................................................................................9

6. Inspection ........................................................................................ 11

7. Storage ............................................................................................ 13

8. Repair and Maintenance .............................................................. 13

Appendix 1:Routine Inspection..................................................... 14

Appendix 2:Annual Inspection ..................................................... 15

Contents

1 2

SL-R60S Fall Arrester

Limited Warranty

3S Lift warrants that commencing from the date of shipment to the Customer and

continuing for a period of the longer of 365 days thereafter, or the period set forth in the

standard 3S Lift warranty, the Product described in this Manual will be free from defects

in material and workmanship under normal use and service when installed and operated in

accordance with the provisions of this Manual.

This warranty is made only to the original user of the Product. The sole and exclusive remedy

and the entire liability of 3S Lift under this limited warranty, shall be, at the option of 3S Lift, a

replacement of the Product (including incidental and freight charges paid by the Customer)

with a similar new or reconditioned Product of equivalent value, or a refund of the purchase

price if the Product is returned to 3S Lift, freight and insurance prepaid. The obligations of

3S Lift are expressly conditioned upon return of the Product in strict accordance with the

return procedures of 3S Lift.(i) has been altered without the authorization of 3S Lift or its

authorized representative;

This warranty does not apply if the product:

(ii) has not been installed, operated, repaired, or maintained in accordance with this

Manual or other instructions from 3S Lift;

(iii) has been subjected to abuse, neglect, casualty, or negligence;

(iv) has been furnished by 3S Lift to Customer without charge; or

(v) has been sold on an “AS-IS” basis.

Except as specifically set forth in this Limited Warranty,All express or implied conditions,

representations and warranties, including, but not limited to, any implied warranty or

condition of merchantability, fitness for a particular purpose, non-infringement, satisfactory

quality, course of dealing, law, usage or trade practice are hereby excluded to the maximum

extent permitted by applicable law and are expressly disclaimed by 3s lift. If, pursuant to

any applicable law, to the extent an implied warranty cannot be excluded as provided in this

limited warranty, any implied warranty is limited in time to the same duration as the express

warranty period set forth above. Because some states do not permit limitations on the duration

of implied warranties, this may not apply to a given customer. This limited warranty gives

customer specific legal rights, and customer may have other legal rights under applicable laws.

This disclaimer shall apply even if the express warranty fails of its essential purpose.

In any cases of dispute, the Chinese original shall be taken as authoritative.

3 4

SL-R60S Fall Arrester

Precautions

withstand the loads specified in the

standards.

1.3 The operator must have obtained a

proper professional training, be familiar

with the operation and installation of

product, and have the ability to attach,

detach and use the product. The

operator must always wear personal

protective equipment, such as safety

helmet, safety shoes and safety gloves,

etc.

1.4 Maximum of 2 operators are allowed on

the same ladder and to attach to the fall

protection system at a time, in which

case a minimum distance of 6 m must

be maintained between them.

1.5 The operator may not be protected

against hitting the ground or the starting

platform within the first 2 m climbing.

Therefore, particular caution must be

taken when operator starts climbing.

The Manual is supplied in the language of

the designated country where the product

is used. The translations in various languages

must be authorized by 3S Lift. The operator

must read, understand and follow these

complete product instructions. Failure to do

so may cause severe injury or death. Keep the

product instructions for future references.

1.1 The fall arrester is an integral component

of fall protection system which falls

into category of personal protection

equipment (PPE). Both the fall arrester

and fall protection system we offer

conform to EN353-1:2014+A1: 2017, ANSI/

ASSE Z359.16-2016 and CSA Z259.2.4. The

fall arrester shall be used in conjunction

with a full body harness that is fitted

with a sternal attachment point in

accordance with EN361 and ANSI Z359.11.

1.2 The ladder on which the fall protection

system is mounted should conform

to EN131-2, EN 14122-4, ANSI A14.3 and

1.6 When attaching or detaching the fall

arrester to/from fall protection lifeline,

ensure that the operator is at a safe

position and protected by a separate

personal protection equipment.

1.7 To achieve the optimal operation and

improve safety, keep a minimum

distance of 100mm between torso and

ladder during normal climbing, and

keep correct climbing postures.

1.8 The weight of the operator (including

tools and equipment) shall not exceed

the rated load of 140 kg (310 lbs).

1.9 The weight of the operator (excluding

tools and equipment) shall not be less

than 30 kg (66 lbs).

1.10 The fall arrester shall never be used

for work positioning or for securing

equipment. If work positioning at the

ladder is required, a separate dedicated

and approved work positioning

equipment shall be used.

1.11 A fall arrester can only be used by one

operator at a time.

1.12 Service temperature of fall arrester is

-40°C to +60°C. Ensure that the system is

free of grease oil and ice.

1.13 According to OSHA 1926.1053, the

connection between the fall arrester and

the attachment point of the full body

harness shall not exceed 23 cm (9 inches)

in length! The length of the connection

shall not be extended or shortened, e.g.

by adding or subtracting a connector.

1.14 Always wear a full body harness that

perfectly fits. If it becomes loose during

ascent or descent, adjust it to a snug fit

in time at a safe position.

1.15 The operator must be in good health

without acrophobia, hypertension,

or heart disease, and not be under

influence of alcohol or drugs during

operation.

1.16 If the equipment is found abnormal

during operation, the operator must

immediately stop using it and notify the

equipment administrator.

5 6

SL-R60S Fall Arrester

1.17 No modification or extension of the

fall protection system shall be allowed

without prior written consent of 3S

Lift. Otherwise for any consequences

affecting the product performance

and safety, 3S Lift will not assume any

liabilities.

1.18 DO NOT carry tools or materials by hands

while climbing up or down the ladder,

during which a fall of tools or materials

may occur resulting in damage to

equipment or injury to personnel below.

1.19 Before each use, perform a routine

inspection to ensure that the fall

arrester functions properly. The annual

inspection shall be performed by a

competent person

1.20 A copy of the user’s manual must be

handed out to the operator and must be

available for reference.

1.21 Before and during use of the fall

protection system, a rescue plan

which copes with all kinds of possible

emergencies should be in place.

1.22 The fall arrester can only be used in

conjunction with 3S Lift rail guided fall

protection system, or a written consent

by 3S Lift shall be obtained if it is

intended to be used with other systems

other than described herein. Otherwise,

for any consequences affecting the

product performance and safety, 3S Lift

will not assume any liabilities.

1.23 The installation, maintenance and

inspection of the fall protection system

can only be performed by qualified

personnel trained by 3S Lift, or under the

guidance of related professionals.

1.24 Follow site emergency protocol. Do not

use the fall arrester as an assisted rescue

device.

1.25 DO NOT use the fall protection system in

environments where the user is exposed

to hazards such as high heat, chemicals

or falling risks that could result in injury

to the user.

1.26 Long distance climbing may require

several movable rest standings mounted

in the climbing passage to avoid fatigue.

Use proper work positioning equipment

for rest breaks. Do not climb in strong

winds or adverse weather.

1.27 Always maintain three points of contact

(hands and feet) with the ladder while

climbing. Should a mis-locking of the fall

arrester occur, the operator shall climb

up a bit to unlock the fall arrester.

Note: Should the fall arrester lock on the

guide rail, never unlock it by means of

detaching it off the guide rail.

1.28 If the fall arrester has been subjected to

a fall which leads to deformation, it must

be removed out of service immediately

and scrapped.

1.29 The ladder onto which the fall

protection system is mounted can be

installed on the tower wall in accordance

with the information supplied by the

manufacturers (see Fig. 1.1 and Fig. 1.2).

For example: weld a base plate with

embeded bolt onto the wall of wind

turbine tower, mount a supporting

bracket onto base plate, and fix the

supporting bracket to the ladder stile

with a clamp. The ladde should have a

capacity of supporting static load of 16

kN (3600 lbs).

Fig. 1.1

Fig. 1.2

7 8

SL-R60S Fall Arrester

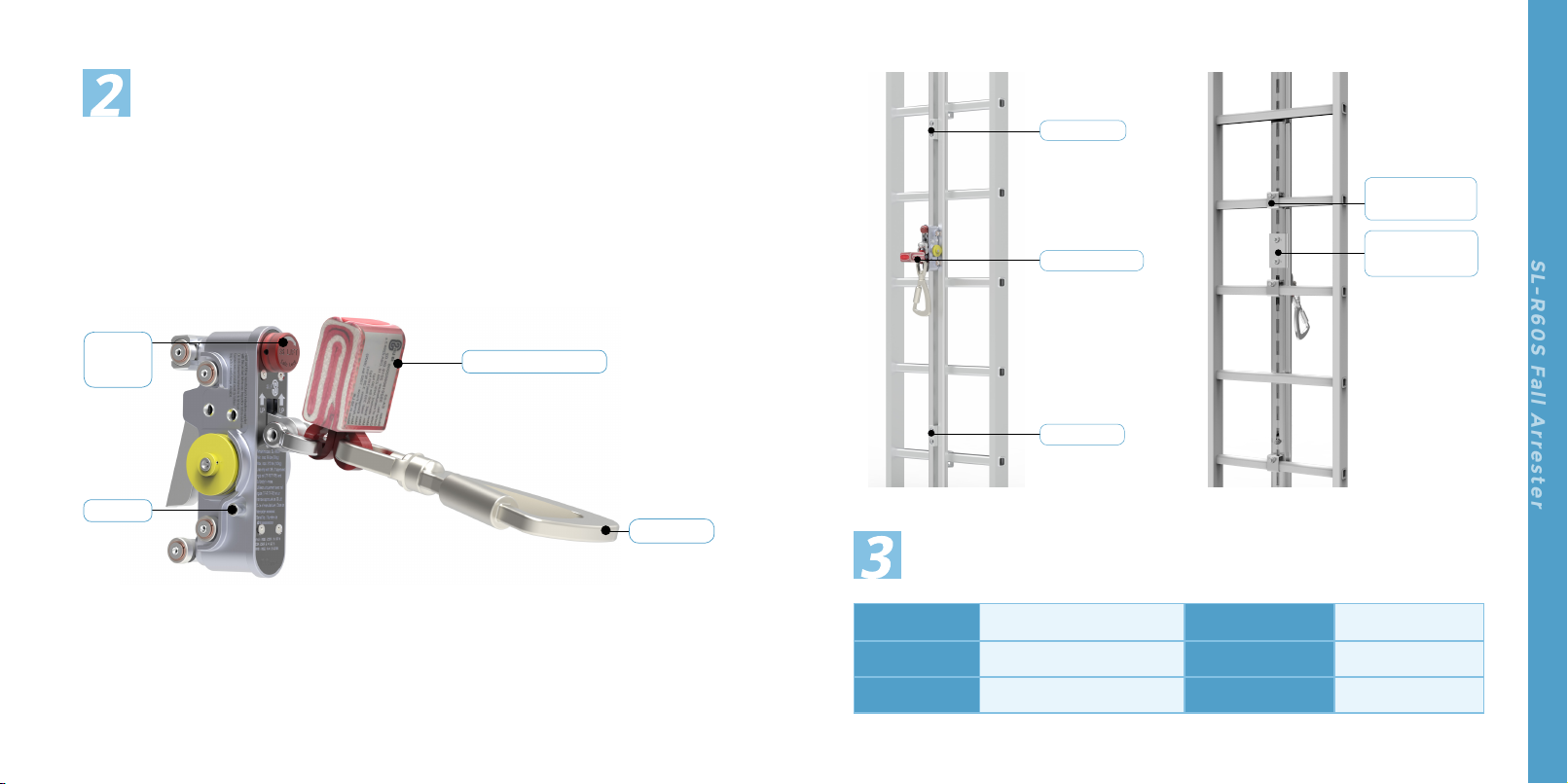

Product Description & Components

Fall arrester (SL-R60S) is used on the rigid guide rail lifeline. When using the fall arrester,

connect the carabiner of fall arrester onto the sternal attachment point of operator's full body

harness. When a fall occurs, the fall arrester will lock on the guide rail automatically.

2.1 The fall arrester is shown in Fig. 2.1 .

2.2 Rigid guide rail lifeline is shown in Fig. 2.2 and Fig. 2.3.

Fig. 2.1

Rotary

knob

Button

Carabiner

Shock absorber

Fig. 2.2 Fig. 2.3

Clamp and

fasteners

Rail fishplate

and fasteners

Specications

End stop

End stop

Fall arrester

Model SL-R60S Self Weight 1.75 kg (3.9 lbs)

Static strength 16 kN (3600 lbs) Rated Load 140 kg (310 lbs)

Dimensions 280 mm× 160 mm× 61 mm Guide Rail Model TF-R/ TF-R5

9 10

SL-R60S Fall Arrester

Marking

The markings shall be legible and clear. During maintenance, check the engraved markings. If

they are not clearly legible, return the fall arrester to 3S Lift for repair. The marking details are

shown in the following figures (See Fig.4.1, Fig.4.2 and Fig.4.3)

FIg. 4.1

Fig. 4.2

Read instructions before use

Fig. 4.3

Attaching direction

Model

Compatible guide

rail model

Load capacity

Serial No.

Reference standard

11 12

SL-R60S Fall Arrester

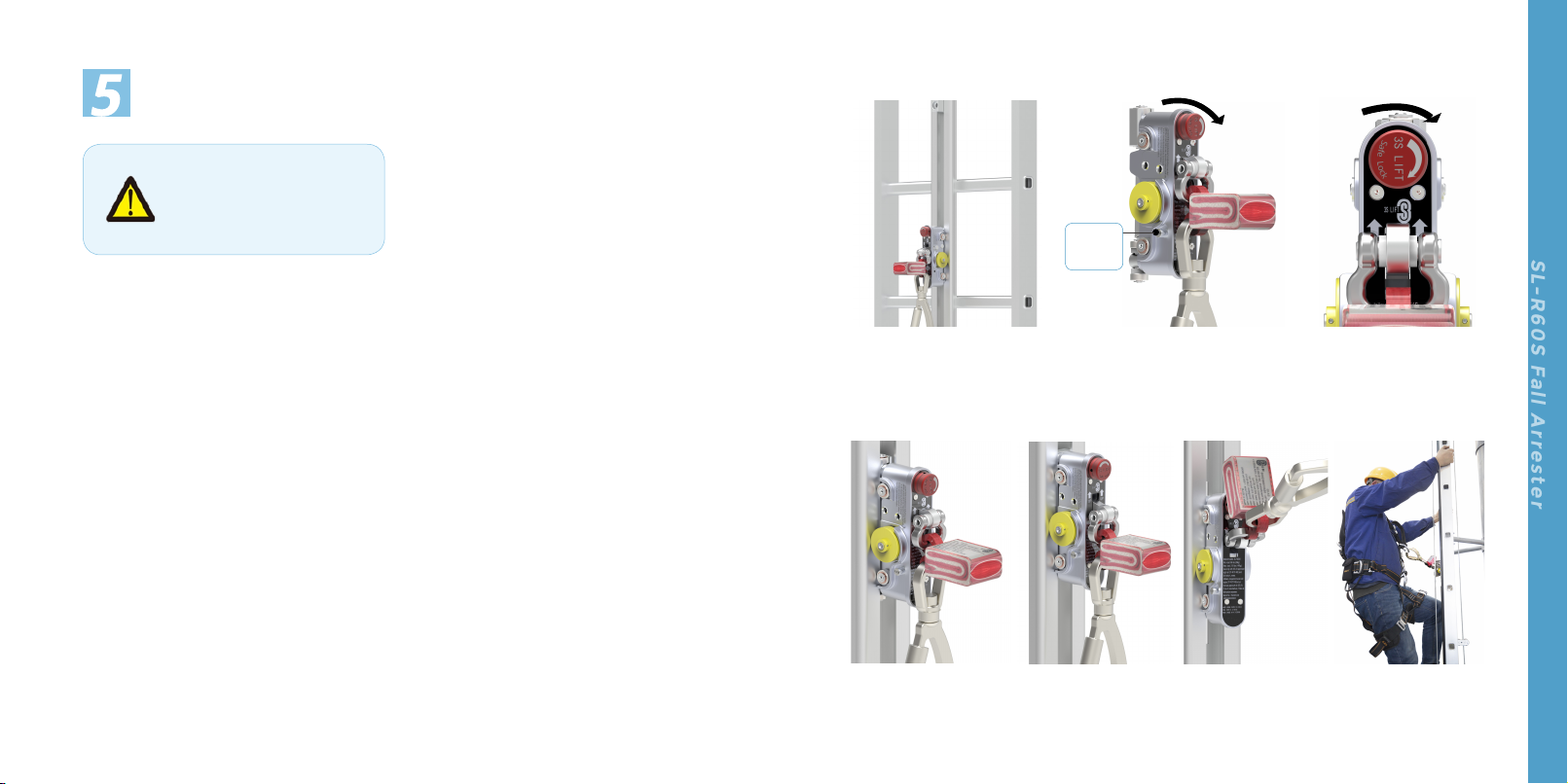

Attention!

Ensure that the safety

carabiner is fully closed and

locked.

Operation

5.1 Attach the fall arrester to the guide rail at

any position. The guide rail should have

been installed along the central line of

the ladder. (As in Fig. 5.1)

5.2 Press down the button and turn the

rotary knob clockwise to its limit, hold

the button and knob, and put the rollers

into the slot of the guide rail. (See Fig. 5.2,

Fig. 5.3 and Fig. 5.4.)

5.3 Release the button and the rotary knob

to let them return to their original

positions. (See Fig. 5.5)

5.4 The fall arrester is ready for use. (See Fig.

5.6)

5.5 Connect the carabiner to the sternal

attachment point of the full body

harness, and ensure the gate of the

carabiner is closed and locked. The fall

protection system is well established for

fall protection at the time.(See Fig. 5.7)

5.6 To detach the fall arrester, press down

the button and turn the rotary know

clockwise, hold the button and knob, and

detach the fall arrester off the rail. (See

Fig. 5.8)

5.7 Release the button and rotary knob to let

them return to their original positions. (As

in Fig. 5.9)

5.8 Open the the gate of the carabiner to

disconnect it from the full body harness

of the operator.

5.9 The fall arrester is integrated with anti-

reverse mechanism, which disenables

the user to turn the rotary knob if he

attempts to attach the fall arrester

upside-down, therefore making reverse

attaching impossible. (See Fig. 5.10)

Fig. 5.1 Fig. 5.2 Fig. 5.3

90°

90°

Press

down

Fig. 5.5 Fig. 5.6 Fig. 5.7

Fig. 5.4

13 14

SL-R60S Fall Arrester

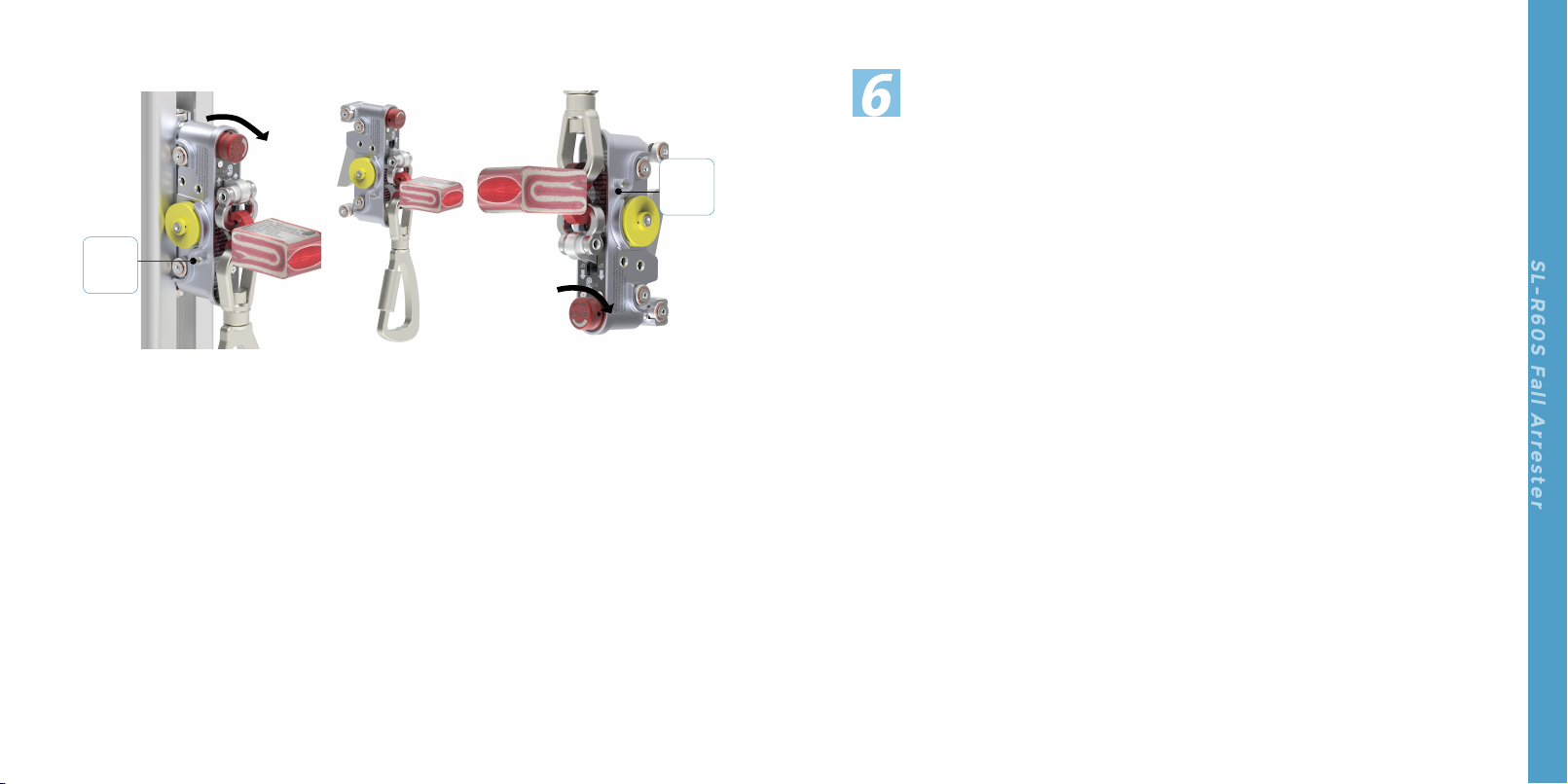

Fig. 5.8 Fig. 5.9 FIg. 5.10

90°

Press

down 90°

Press

down

Inspection

The fall protection system shall be inspected

at least once a year by a certified technician,

and can be used only if the inspection reveals

no problem. If a fall occurs, inspection and

maintenance of the fall protection system

including fall arrester, guide rail and ladder,

etc. must be performed by competent

personnel other than the operator.

Note: Use a separate fall protection system

while inspecting and maintaining the

fall protection system.

If any fault or defect of the fall protection

system is found during routine inspection or

annual inspection, the fall protection system

shall not be used until troubleshooting

is conducted. The fault or defect shall be

reported to the equipment administrator,

and the system including the fall arrester

shall be inspected by competent personnel

who should record the fault or defect and

decide on repair or scrapping. Before each

use, conduct routine inspection of the system

in accordance with Section 6.1 and Section

6.2.

6.1 Visual check

6.1.1 Check the guide rail: During upward

climbing, visually check the guide

rail and its joints for any damage or

deformation. Ensure that all fasteners

are secured well, and guide rail

sections have been correctly installed

in accordance with instructions.

6.1.2 Check the fall arrester: check the

locking lever and swing lever for any

damage or deformation. Ensure that

the shock absorber is complete and has

not extended, and that the carabiner is

complete without break or crack.

6.2 Function check

6.2.1 Check whether the fall arrester

functions normally by following the

instructions below. Stop using if any

damage or defect is found.

6.2.2

Press down the button on fall arrester

and turn the rotary knob clockwise (to

its limit) simultaneously, hold and then

15 16

SL-R60S Fall Arrester

release both the button and

rotary knob and see whether they

automatically return to their original

positions.

6.2.2

Press down the button on fall arrester

and turn the rotary knob clockwise

(to its limit) simultaneously, hold and

then release both the button and

rotary knob and see whether they

automatically return to their original

positions.

6.2.3 Pull the fall arrester up and down the

rail, then release it and see whether it

locks on the guide rail immediately.

6.3 Annual Inspection

6.3.1 Perform the visual check and function

check following clause 6.1 and clause

6.2 during annual inspection.

6.3.2 Ensure that the locking lever and swing

lever rotate without clamp stagnation

when the carabiner of fall arrester is

pulled up, and automatically return

to their original positions when the

carabiner is released.

6.3.3 Ensure that the fall arrester is free of oil,

grease, dust and the like. Clean the fall

arrester if necessary with steel wire or

brush in such manner as not to cause

component damage. If the fall arrester

does not function normally due to oil

or dirt, return it to 3S lift for repair.

6.3.4 Ensure that all shafts and other

components are secured well and all

rollers rotate freely.

6.3.5 If any malfunction or defect is found

before or during inspection, the fall

arrester shall not be used further

and shall be returned to 3S Lift for

repair. An annual inspection of the fall

protection system shall be performed

by competent personnel, during which

any abnormality should be recorded

and maintained.

6.3.6 Inspect the connection between the

ladder and the fall protection system

to verify that the ladder equipped

with fall protection system is in good

working condition. In case of damage,

deformation or other defects, notify the

relevant person.

Note:Parts which are not provided or

approved in written by 3S Lift shall not

be used.

6.3.7 Ensure that the guide rail is in good

condition without deformation,

cracks or other defects, and its joints

(between its sections) are aligned with

a clearance less than 2 mm.

6.3.8 Check all labels of the fall protection

system for damage or loss, and replace

with or affix new labels as needed.

6.3.9 Ensure that all end stops, fish plates

and fasteners of the fall protection

system are secured well.

6.3.10 Ensure that the metal parts of fall

arrester show no signs of corrosion and

oxidation. If any, consult competent

personnel of 3S lift who will determine

between replacement or scraping.

6.4 Criteria of disposing the fall

arrester

6.4.1 The fall arrester is designed with

service life of 5 years. However, the

actual service life is dependent on use

Fig.6.1 Fig.6.2

environment, temperature, storage and

frequency of use. Extreme temperature,

fall, or contamination by harmful

substances will adversely affect the

service life.

6.4.2 If the routine inspection or annual

inspection reveals that the fall arrester

fails to meet prescribed criteria and

cannot be repaired, the fall arrester

shall be scrapped.

6.4.3

A fall arrester which has blocked a fall

shall not be used any more.(As in Fig. 6.1

and Fig. 6.2)

17 18

SL-R60S Fall Arrester

Repair and maintenance

8.1 When the guide rails and the fall arrester

are found to be contaminated by

corrosive substances such as oil, grease,

paint or other substances during the

inspection following clause,8, please

clean them with warm water and a little

soft detergent. Do not use other cleaning

agents.

8.2 Wipe it off with a clean cloth and then

dry them in air. Do not dry with an

artificial heat source.

8.3 If necessary, a small amount of oil can be

added at the contacts between the rollers

and the shafts, to ensure that the rollers

smoothly rotate without abnormal noise.

8.4 Repair and maintenance must be carried

out by a qualified person who must be

familiar with and fully understand the

instructions.

7.1 Personal protective equipment should be

stored in a cool, dry, clean environment,

and out of direct sunlight.

7.2 Do not expose the fall arrester and full

body harness to the corrosive substances

including oil, grease, paint or other

chemicals. Otherwise the service life of

the product might be shortened.

7.3 The reconstruction or modification of

fall arrester is not allowed. 3S Lift will not

assume any responsibility of any injury

or death caused by reconstruction or

modification of the fall arrester.

7.4 The fall arrester and full body harness

should be stored and carried in tool kit or

packing box.

Storage Routine Inspection

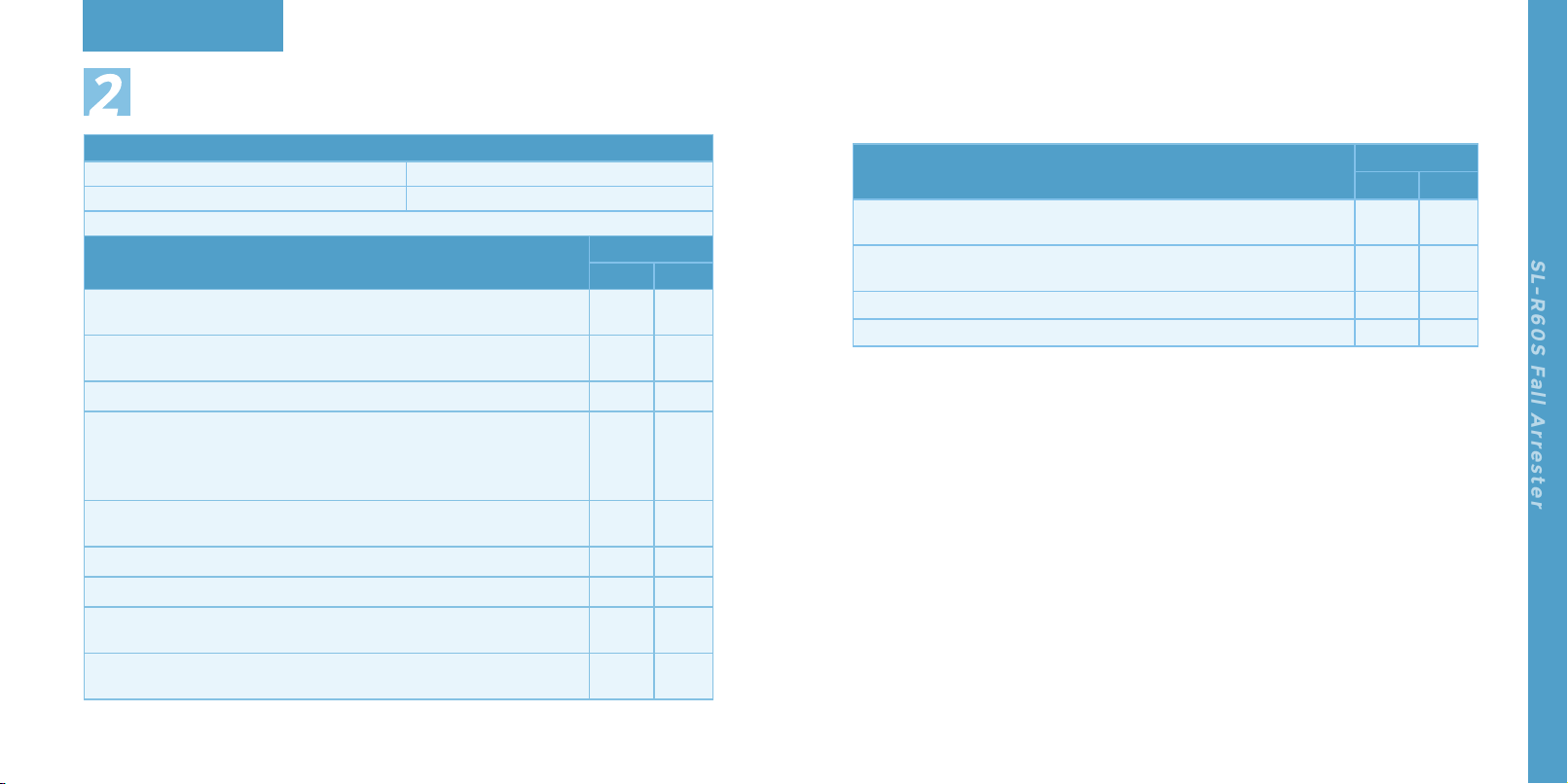

Inspection record

Date of inspection: Model/Standard:

Inspected by: Serial number:

Date of initial use:

Inspection items Remarks

Yes No

1. Check and ensure no damage, oil, dust, or dirt on the surface of the fall

arrester.

2. Check and ensure no deformation or fracture of the carabiner. Check

and ensure that the gate of the carabiner can be closed and locked

automatically.

3. Check and ensure all rollers rotate flexibly.

4. Check and ensure no deformation and damage on the fall arrester, and

that the locking lever and swing lever rotate flexibly without clamping

stagnation when the carabiner is lifted, and return to original position

automatically after the carabiner is released.

5. Check and ensure that the push button and rotary knob return to their

original positions after they are released.

6. Check and ensure the shock absorber is intact without being extended.

7. Check and ensure all fasteners are firmly riveted and no obvious tear or

deformation.

This table can only be filled in by competent person, and can be duplicated for further use.

Appendix

19 20

SL-R60S Fall Arrester

Inspection record

Date of annual inspection: Model/Standard:

Inspected by: Serial number:

Date of initial use:

Inspection requirements Remarks

Yes No

1. Check and ensure no damage, oil, dust, or dirt on the surface of the fall

arrester.

2. Check and ensure no deformation or fracture of the carabiner. Check

and ensure the gate lock of carabiner can be automatically closed.

3. Check and ensure all rollers rotate flexibly.

4. Check and ensure no deformation and damage on the fall arrester, and

that the locking lever and swing lever rotate flexibly without clamping

stagnation when the carabiner is lifted, and return to original position

automatically after the carabiner is released.

5. Check and ensure that the push button and rotary knob return to their

original positions after they are released.

6. Check and ensure the shock absorber is intact without being extended.

7. Check and ensure the joint gap is less than 2mm.

8. Check and ensure that when the fall arrester moves along the guide rail,

no abnormal noise is heard.

9. Check and ensure all connections by riveting are secure without obvious

wear, deformation or dislocation of torque marks.

Annual Inspection

Appendix

Inspection requirements Remarks

Yes No

10.Ensure no deformation, cracks or looseness on the ladder and guide

rail.

11. Ensure that the end stops on the rail type fall protection system are

mounted properly.

12. Ensure that all mounting brackets and fasteners are well secured.

13. Ensure completeness and legibility of the markings on the fall arrester.

This table can only be filled in by competent person, and can be duplicated for further use.

Table of contents

Popular Safety Equipment manuals by other brands

Lanex

Lanex PB-20 instruction manual

SKYLOTEC

SKYLOTEC ANCHOR ROPES Instructions for use

Besto

Besto Buoyancy Aid 50N Instructions for use

TEUFELBERGER

TEUFELBERGER NODUS Manufacturer's information and instructions for use

Troy Lee Designs

Troy Lee Designs Tbone Product owners manual

Innova

Innova Xtirpa Instruction and safety manual

bolle SAFETY

bolle SAFETY B810 quick start guide

SHENZHEN FANHAI SANJIANG ELECTRONICS

SHENZHEN FANHAI SANJIANG ELECTRONICS A9060T instruction manual

Hiltron security

Hiltron security POWER8E Installation and use manual

Salewa

Salewa MTN SPIKE user manual

Hatco

Hatco B-950P installation guide

Sitec

Sitec TX MATIC operating manual