120 - 150i B2 / TS / CS front and rear Engine Manual

through

the cylinder(s)

fins.

The

freely

flowing, but

directed and

turbulent air

between

the

fins

provides

the maximum

cooling

for

an

air

cooled engine. Without

ba

f

fling

(meaning wood

or

composite dampers

that direct

the

airflow)

the

air

will

t

ake

the

p

ath

of

least

resis

t

ance. Some

incoming air

will

bounce

o

ff

the cylinder(s) and the

rest

will

escape

around the cylinder(s)

without

coming

into

con

t

act

with

the cylinder(s).

Engine in pusher operation:

Impor

t

ant

note!

When

engines

are

used operating

in

pusher

configuration cooling

ge

ts critical

and

special

attention

has

to

be

given

to

an

e

f

fective

cooling

method. A

good cooling

system

layout

depends

on

the actual

location (position)

of

the engine

in

the fuselage.

Operating temperature

To be able to check the cylinder head temperature ( CHT ) a thermo element has to be installed which fits

under the spark plug ( M 10 thread ). Optimum operating temperature range : 180°C - 220°C. In this range

piston, spark plug and combustion chamber will be free of remains. Maximum temperature of 270°C should

not be exceeded. During a certain time at full speed the temperature could be 250°C.

Colour of the spark plug should be : light or middle brown. A grey / gray colour is a typical sign for over

heating. Temperatures above 270°C are critical and over 300°C, piston can seize and could completely

damage the engine.

Temperatures below 180°C create remains ( carbon ) on the piston crown. Increasing remains hit the

cylinder and cause abnormal running noises ( knocking ) which will increase the load of the needle

bearings and can destroy them. Under extreme conditions the crankshaft can break and a complete

damage of the engine will be the result.

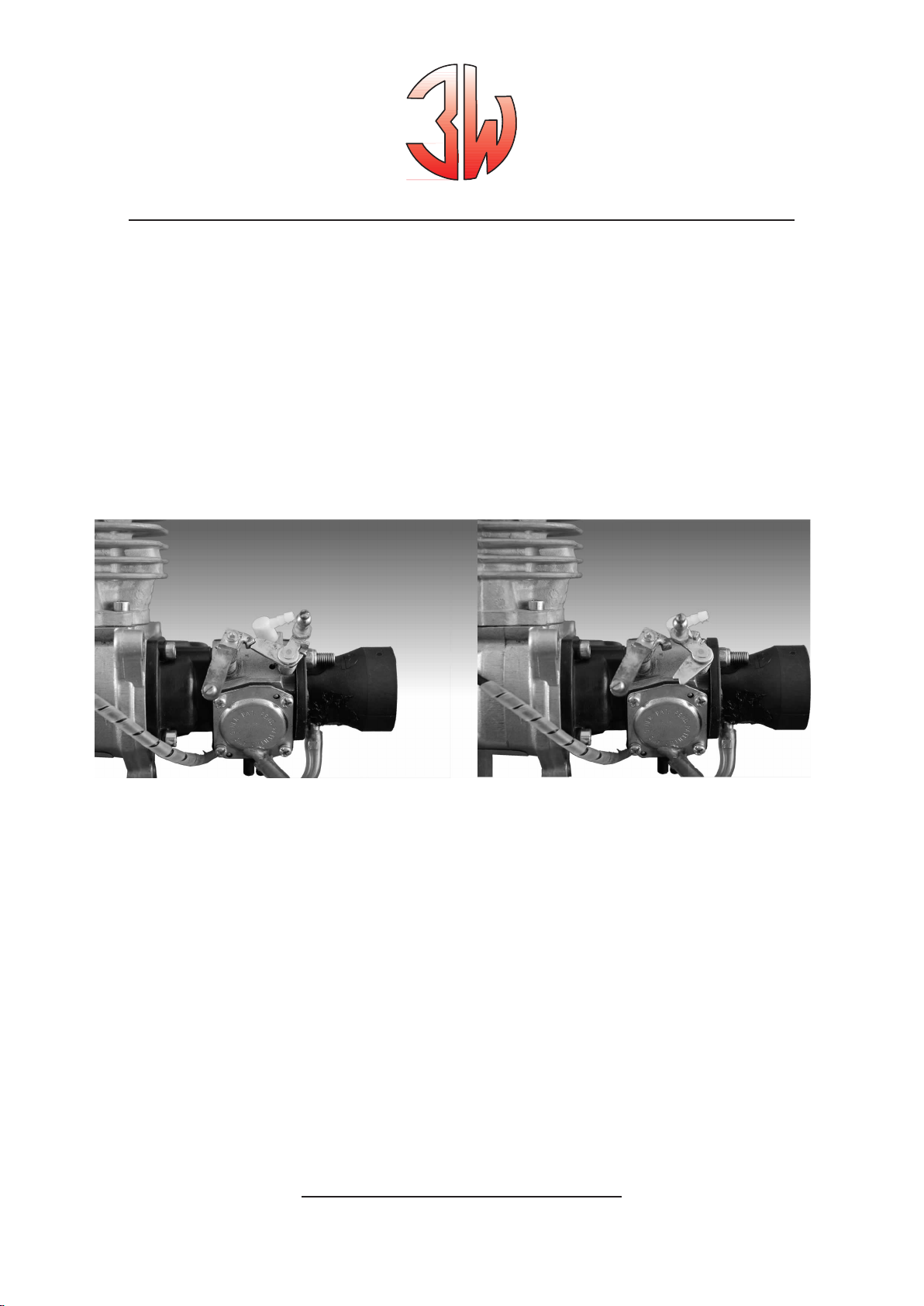

Rear induction

Carburetors, whether

front or

rea

r, require

a

steady

supply

of

fresh

air.

The

best

way

to

supply

air

to

a

rear

carburetor

is

by

ins

t

alling

an

air

scoop.

Some have

thought

to

drill

holes

into

the

fuselage

near

the carburetor

area

rather than creating

an

air scoop

for

the carburetor. This does

not

work,

it

fact

it

will

create

a

vacuum

e

f

fect that

will

draw the

air

away

from

the

carburetor!

Again,

you should

ins

t

all

an

air scoop

into

the

front of

the plane

which

will

supply air

into

the fuselage.

This

air

will

then

need

to flow

out

of

the fuselage.

Drill

exit

holes

into

the

rear

area

of

the fuselage

for this

purpose. Impor

t

ant:

The

interior of

the fuselage

must

be sealed

to

prevent

damage

from

gasoline

that

sprays

from

the carburetor.

Use

a

thin

epoxy

or

other appropriate

fuel proofing

method.

Do

not overlook

this

step

as

gasoline

will

melt some materials

like

S

tyrofoam

very

quickl

y.

www.3w-modellmotoren.com