ENGLISH 6

4 FITTING

4.1 Inspect door / door system

Thedoormustbeinaawlessmechanicalcondition,aswell

as correctly balanced, so that it can be easily operated by hand

(EN 12604).

►Lift the door by approx. one metre and let it go. The door

should stay in this position and neither move downward nor

upward. If the door does move in either direction, there is

a danger that the compensating springs / weights are not

properly adjusted or are defective. In this case, increased

wear and malfunctioning of the door system can be expected.

►Check whether the door can be opened and closed correctly.

►The mechanical locking devices of the door that are not

needed with a garage door operator must be put out of

commission. This especially includes the locking mechanisms

of the door lock.

►Thettermustcheckthatthettingmaterialssuppliedare

suitableforthepurposeandtheintendedttinglocation.

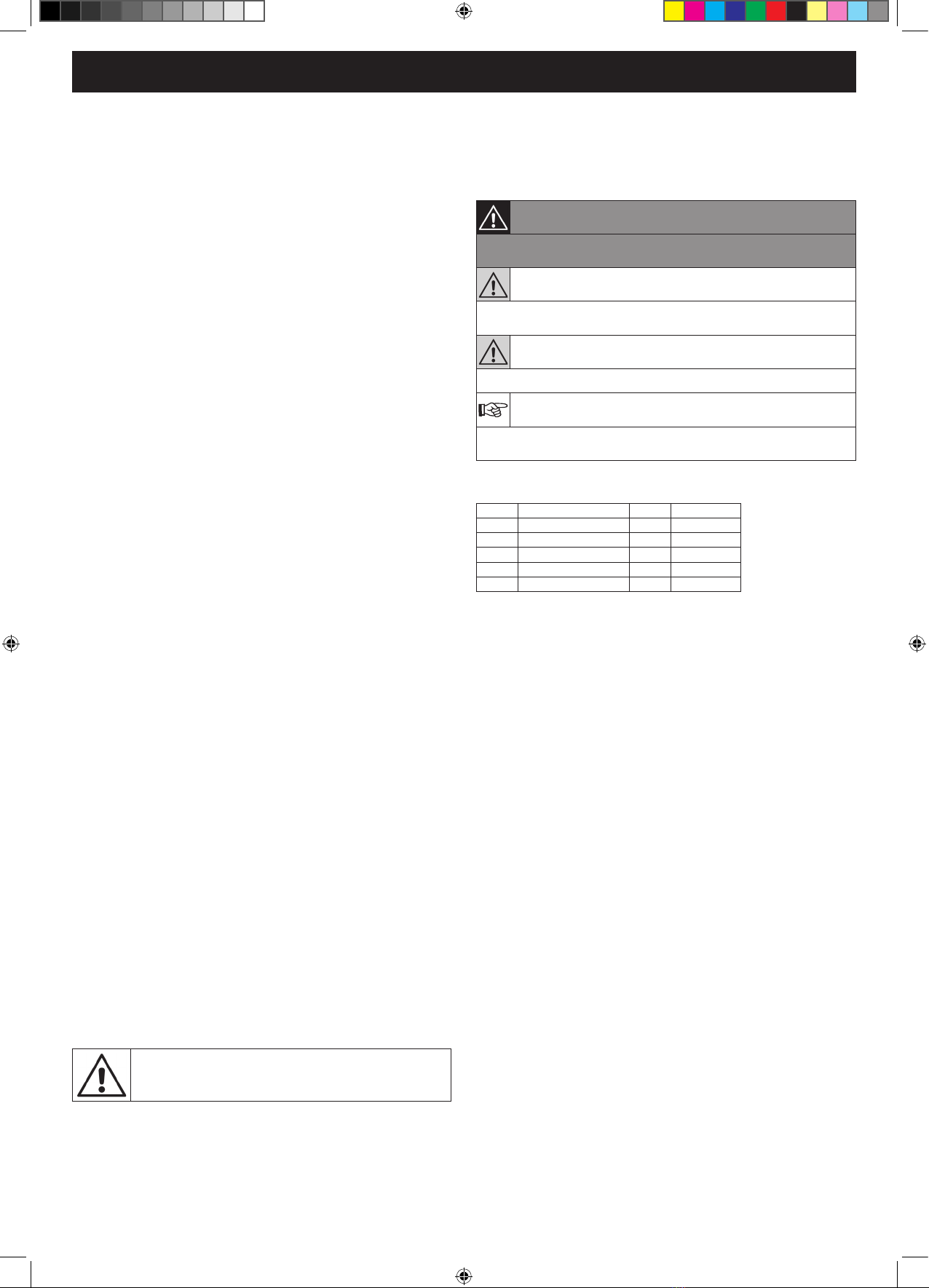

4.2 Clearance required

▪The clearance between the highest point of door travel and

the ceiling (even when opening the door) must be at least

30 mm. See Figures 1.1a and 1.2b.

▪If the clearance is smaller, the operator can also be mounted

behind the opened door if enough space is available. In this

case,anextendedttingbracket(orderedseparately)must

be used.

▪The garage door operator can be arranged up to max.

500 mm off-centre.

▪ Theelectricaloutletshouldbettedapprox.500mmfromthe

operator head.

Check these dimensions!

4.3 Preparing the door

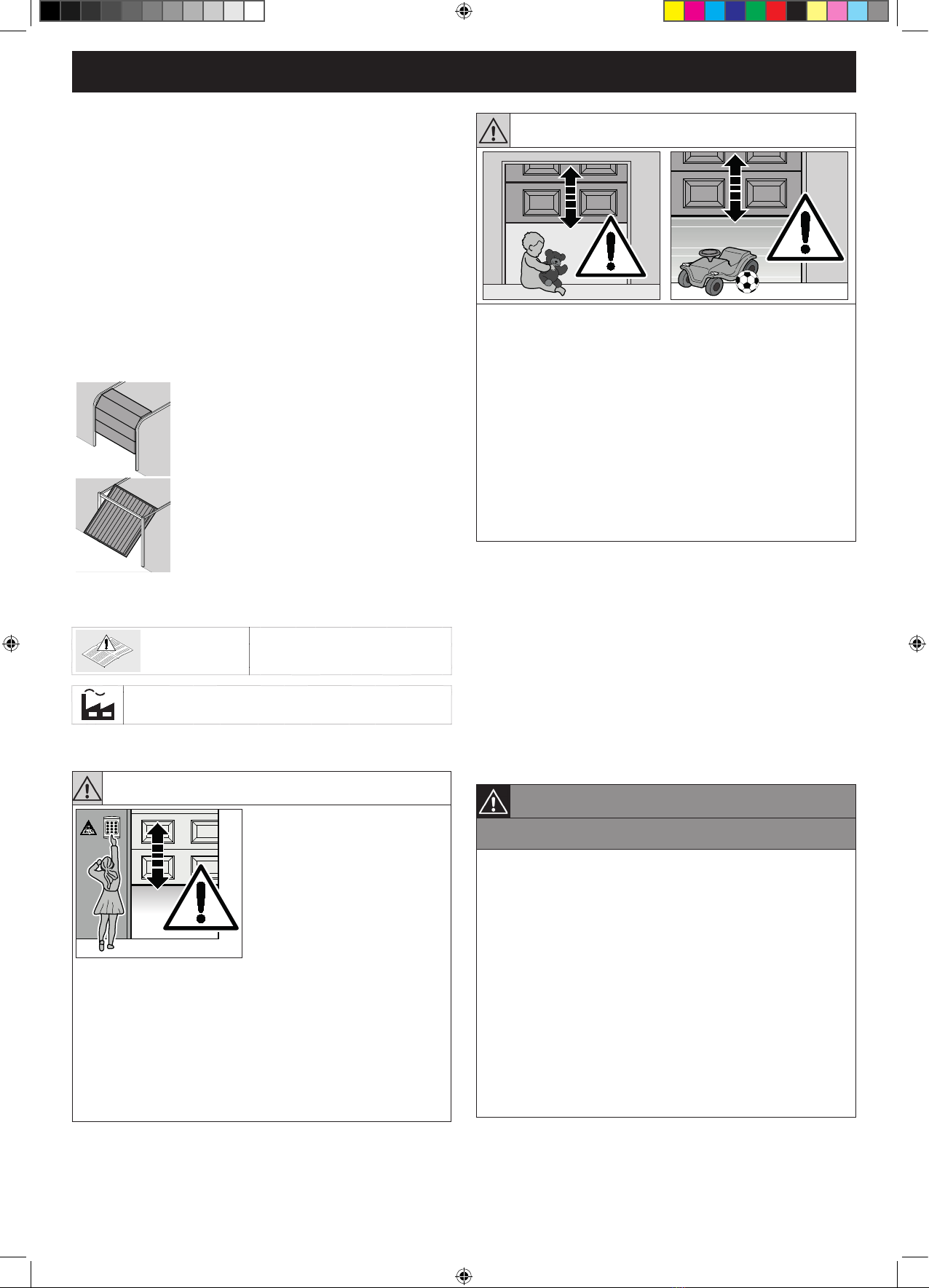

WARNING!

Danger to life from the pull rope!

A running rope may lead to strangulation.

►Removetheropewhilettingtheoperator(seeFigure1.2a).

►Completely disassemble the mechanical door locking on the

sectionaldoor.Seegure1.3aonpage 21.

►Withanoff-centrereinforcementproleonthesectionaldoor,

tthelinkbracketonthenearestreinforcementproletothe

leftorright.Seegure1.5aonpage 22.

►For sectional doors with centre door locking, arrange the lintel

jointandlinkbracketmax.50cmoff-centre.Seegure1.6a

on page 23.

►Render the mechanical door locking on the up-and-over door

inoperable. For door models not covered here, block the

catches on site. See Figures 1.3b/1.4b/1.5b on page 24.

►In a deviation from the illustrated section, attach the lintel

ceiling console and link bracket max. 50 cm off-centre for

up-and-over doors with ornamental iron door handles. See

gure1.6bonpage 25.

►ForN80doorswithtimberinll,thebottomholesonthelintel

jointmustbeusedfortting.Seegure1.7bonpage 25.

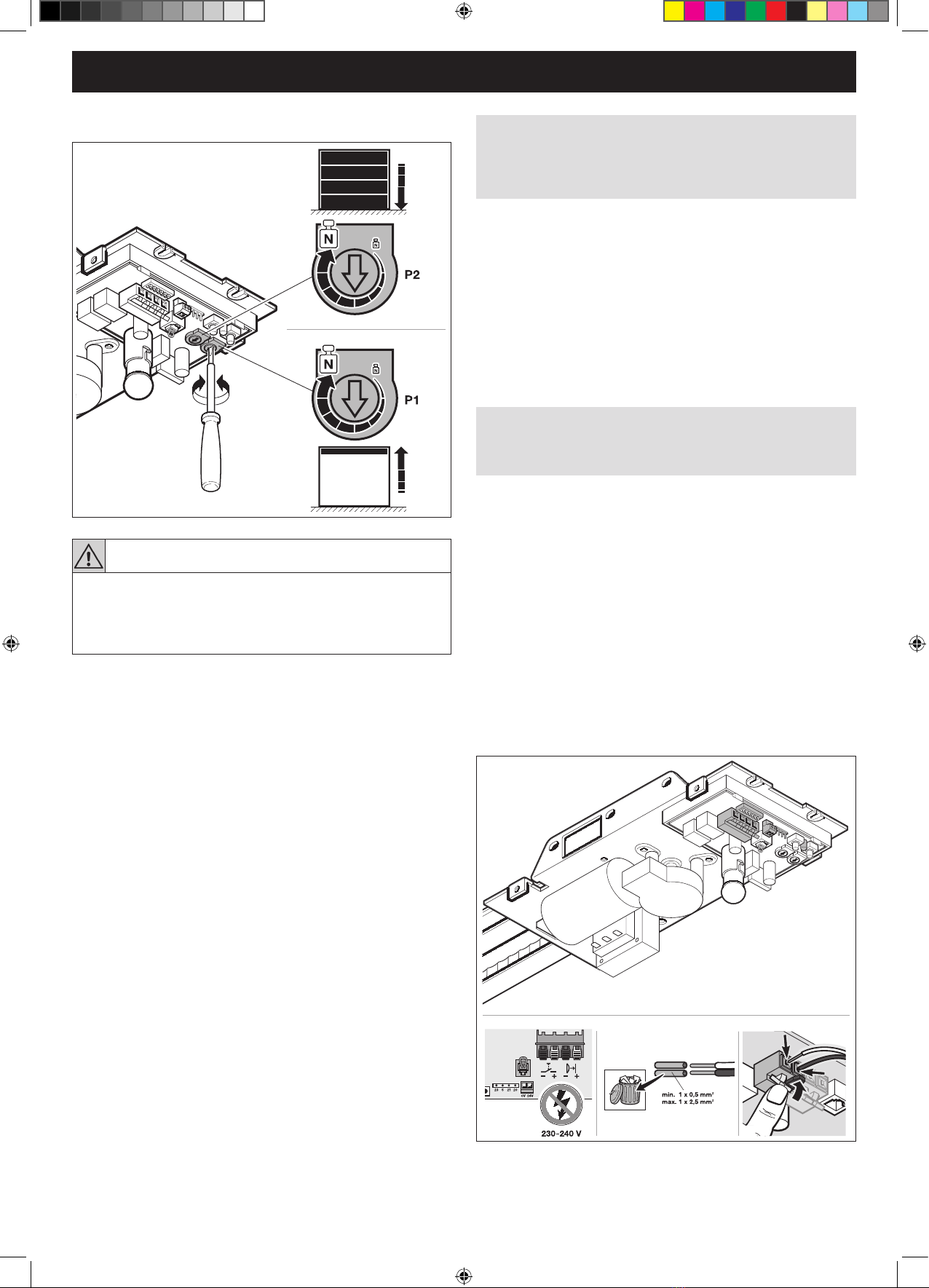

4.4 Fitting the boom

WARNING!

Unsuitable xing material

Useofunsuitablexingmaterialmaymeanthattheoperatoris

insecurely attached and could come loose.

►Thettermustcheckthesuitabilityoftheprovidedxing

material(plugs)foruseintheintendedttinglocation.

►Onlyusetheprovidedxingmaterials(plugs)inconcrete

≥B15(seeFigures1.6a/1.8b/2.4).

ATTENTION!

▪Before the boom is fi tted on the lintel and under the ceiling,

shift the slide carriage approx. 20 cm towards the middle of

the boom. This is no longer possible once the end stops and

operator have been fi tted.

▪Only use the booms recommended by us for the garage door

operators – depending on the respective application!

▪Drilling dust and chippings can lead to malfunctions.

Cover the operator during drilling work..

Note

A second suspension is recommended with divided rails

(availableunderaccessories)(seegure2.5onpage 27).

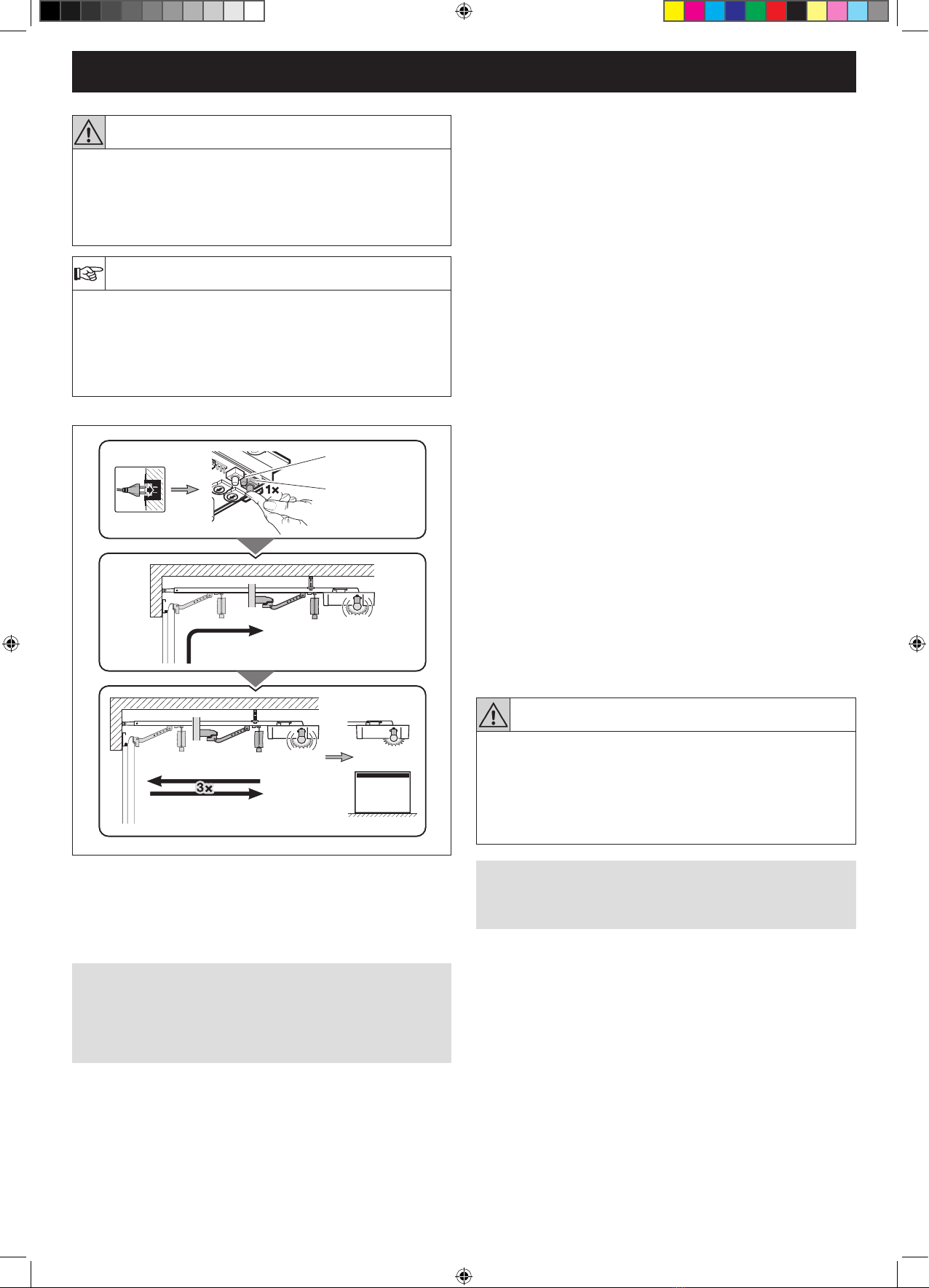

4.5 Boom operating modes

4.5.1 Manual operation

The slide carriage is disengaged from the belt lock to enable the

door to be moved by hand. For disengaging the slide carriage:

Pull on the cord of the mechanical release.

Seegure4onpage 30.

4.5.2 Automated operation

The belt lock is engaged in the slide carriage to enable the door

to be moved with the operator. For preparing the slide carriage

for engaging:

• Pressthegreenknob.Seegure6onpage 30

• Move the belt in the direction of the slide carriage until the belt

lock engages.

4.6 Emergency release

WARNING!

Danger of injury by fast-closing door!

If the cord knob is actuated while the door is open, there is a

danger that the door will close rapidly if the springs are weak,

broken or defective, or if the counterbalance is inadequate.

►Only pull the cord knob when the door is closed!

An emergency release is necessary for garages without a

second entrance that prevents the possibility of being locked

out; this must be ordered separately.

►Check the emergency release monthly for proper function.

EBA GA103_4ddoors_GBR, Rev. 1.0, 25.04.2014.indb 6 5/26/2014 9:53:22 AM