Page 3Pro-150 controller instructions

3Safety

Electric motors and batteries are dangerous. Any

motor controller can only operate properly in a

properly designed and functioning environment.

The Pro-150 can deliver short-term currents in excess

of 150 amps. Batteries of the sort commonly used

can delivered a huge mount more current: faulty

wiring or components can therefore cause the

batteries, the motor and their wiring to be a potential

fire risk.

A digital controller performs checks on its wiring as

it is switched on, and also does certain checks 'on the

fly' during operation. These checks should catch

most faults (inside the controller, as well as outside)

but conditions of operation, programming and use are

outside our control and 4QD can accept no liability

for the results of any fault.

Suggestions for wiring etc are given in good faith

and will suit most customers. 4QD can however

accept no liability for the design of your particular

machine: it is up to the machine manufacturer to

make sure that the machine is safe under any and all

fault conditions.

Circuit breaker

Faults in the battery or motor wiring pose a fire risk,

as well as introducing the possibility of uncontrolled

operation. You should make sure your batteries have

adequate circuit breakers to disconnect them in the

event of such fault, or in he event of unforeseen

circumstances where the power must be

disconnected.

Mechanical braking

In a controller with regenerative braking, mechanical

brakes are hardly used. However, it is the battery that

is doing the actual braking, not the controller. Faults

in the battery or any of the power wiring can

therefore render regenerative braking inoperative.

Mechanical braking should then be fitted as a safety

precaution.

Mounting

The controller must be mounted so that water and

dirt cannot contaminate it. The metal base plate

must not be modified as this will produce metal

swarf Such contamination is likely to compromise

the controller's safety features and can make it

behave in an unsafe manner or even destroy it.

Such damage caused by contamination will not be

repaired under the guarantee.

If water or other contamination does enter the

controller you must disconnect the battery

immediately and clean or thoroughly dry out the

controller before re-connecting the battery.

The unboxed controller has no protection against

contamination, so should not be used in

environments where this is a possibility.

Metal swarf is the most dangerous kind of

contamination, therefore never cut drill file or work

metal in any way near to the controller or the motor

unless properly sealed. In particular, never modify

the base plate while it is attached to the controller!

The boxed controller, if properly mounted, has

reasonable protection against rain etc.

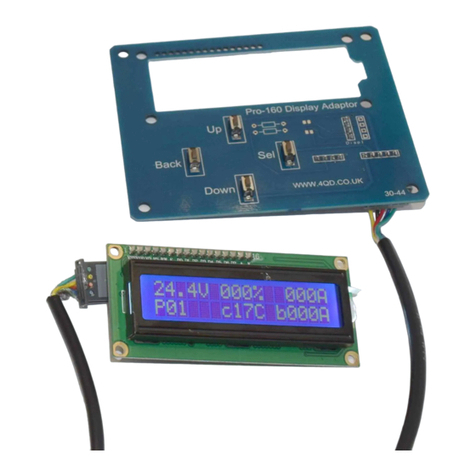

The unboxed controller (or without its cover) and the

display both have full battery voltage present on

them: take great care that no conducting object or

contamination touches them while the battery is

connected. This is particularly likely if you are

accessing them, for instance to alter the performance.

Handling

The capacitors in the Pro-150 can retain charge for a

long while after the battery is disconnected so

immediately after disconnecting the batteries turn on

the ignition for a few seconds to discharge them.