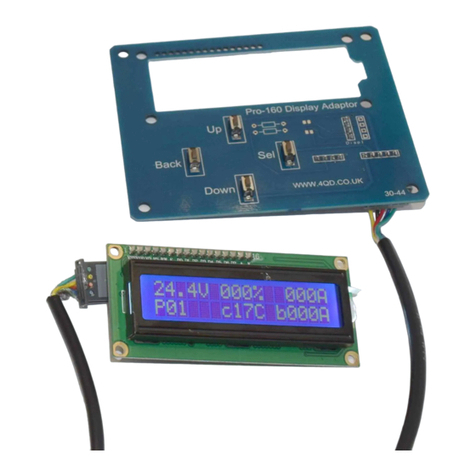

PRO-160 V2.0 10/19 Page 10 www.4qd.co.uk

14. Input configuration

14.1 “Input mode”. Selects the input to be used. Pot will use the signal applied to pin B

of the control port. RC will use the RDO port.

14.2 “Joystick”. Selects either single ended or joystick [center-off / wig-wag] mode.

14.3 “Deadband”. Sets the amount of input required before the output starts.

14.4 “Pot learn”. See Using the “learn” function.

14.5 “RC learn.” See Using the “learn” function.

14.6 “High pot lockout”. Prevents the motor starting if the Pro-160 is switched on with

the throttle not at zero. This setting defines the throttle setting above which this

occurs.

15. Using the “learn” function

The “learn”function allow you to match zero speed, full forward, and full reverse

from the Pro-160 to specific input signals from your pot, radio control receiver, or

other input source.

15.1 Set either “Pot learn” or “RC learn”active [only one per profile].

15.2 Select “Learn zero”and press SEL, the Pro-160 will show a number related to the

value detected from the pot [or other input].

15.3 Set the pot, transmitter stick, or other input to the point you want to have as zero,

and press SEL to capture the associated number.

15.4 Repeat steps 15.2 –15.3 for “Learn max forward” and “Learn max reverse”

15.5 Use BACK to return to the main menu and then save changes.

Note: If you are not using “Joystick” mode, you should set “Learn max reverse” to

the same value as “Learn max forward”. Reverse is then selected by the reverse

switch.