6

Hot water dispensing (to prepare hot drinks such as tea, chamomile, etc.)

Check the level indicator to make sure there is enough water in the boiler.

In case there is not, contact the after-sales service center.

Make sure the water is hot, checking that the boiler pressure gauge indicates a pressure of approximately 0.8 to 1 bar

Place the empty container under the hot water wand and press the button on the touch button panel.

Preparing coffee

- Pour the desired amount of coffee into the filter basket and press it with the specifically designed tamper.

- Insert the filter holder into the group and turn it to the right-

- Place one or two cups under the filter holder spout

- Press the desired selection button . The corresponding LED turns on.

- The machine will automatically stop when the preset amount has been dispensed.

- To interrupt the brewing process at any time, press the selection button again. Our machines have a 3-minute

dispensing time-out, after which the pump and group solenoid valve will stop.

When dispensing is finished, leave the filter holder in the group until the next brewing.

Before dispensing again, empty the grounds into the knock out drawer after having unhooked the filter holder from the

group.

Make sure the pressure gauge indicates a pressure of approximately 8.5 bars (123 psi) during dispensing. If not, adjust

the calibration screw on the pump.

Programming

In order to program the doses, use the push button panel on the right. The push button panel on the left will be

automatically set with the same doses.

- Keep the button pressed for at least 5 seconds.

- All of the LED lights turn on.

- Press the selection button to be programmed. The corresponding LED flashes

- The LED of the button remains on.

- The machine pump and group solenoid valve are enabled.

- When the desired amount has been dispensed, press the button again to stop dispensing.

- Repeat these operations to program the other doses.

- Thirty second after programming, the machine automatically saves the set doses

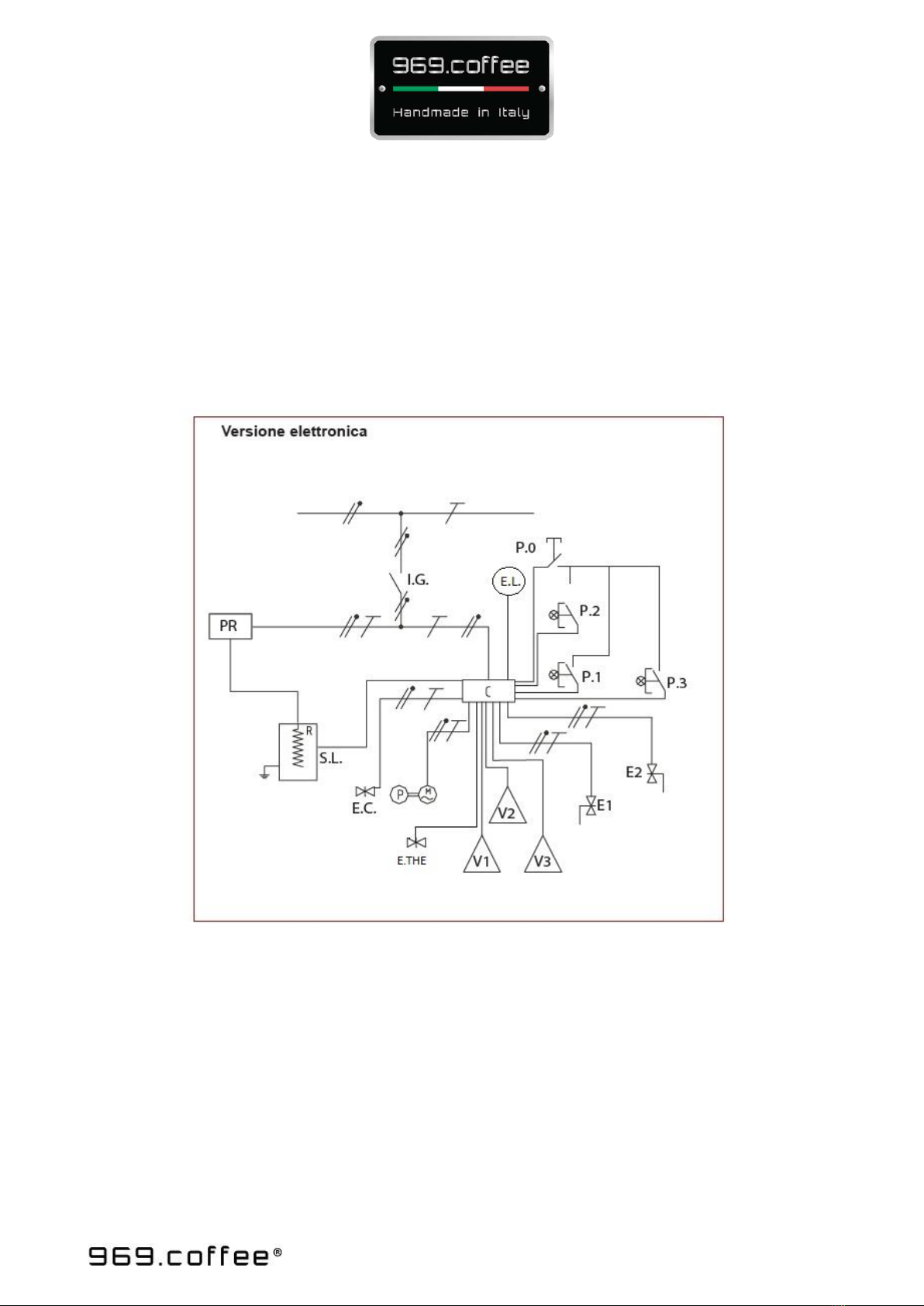

The electronic models are equipped with a control unit.

Periodic controls

On a regular basis, i.e. every 15/20 Kg of coffee, remember to clean the water softener system in order to remove any

calcium salts deposited inside (see the related manual)

Cleaning

To ensure both trouble-free operation of this machine and great-tasting coffee, the machine must be cleaned properly

We recommend repeating the operations below at least once a day and/or after long idle periods!

WARNING!

Turn off the machine and unplug it before carrying out any cleaning operations!

To clean the machine, do not use water jets or immerge it in water!

Do not use solvents, abrasive powders, or steel wool.

Outside

After having dispensed the last coffee, clean the filter baskets and filter holders (Fig. 14) with boiling water, detergent,

and the special brush.

Remove the grid and drip tray (Fig. 15) and use hot water and a sponge to eliminate any residue.

Also clean the external body with a sponge or soft cloth and liquid detergent.

Ducts